Milling tool as well as segment therefor

A milling cutter and cutter body technology, applied in the field of milling cutters and cutter segments, can solve the problems of insufficient machining accuracy, cumbersomeness, complex adjustment and grinding of cutter segments, etc., and achieve simple installation and disassembly, high positioning reliability, high The effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

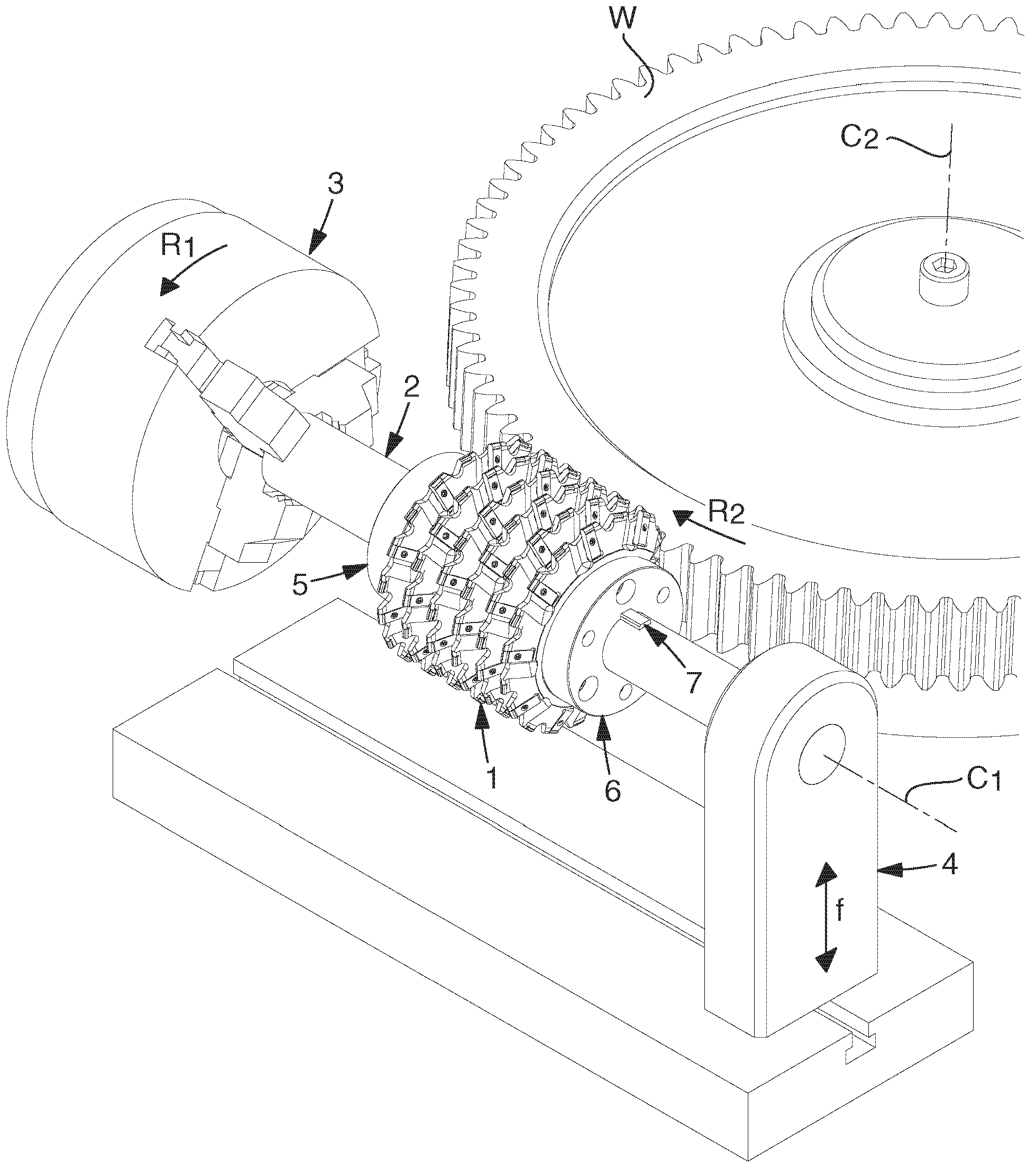

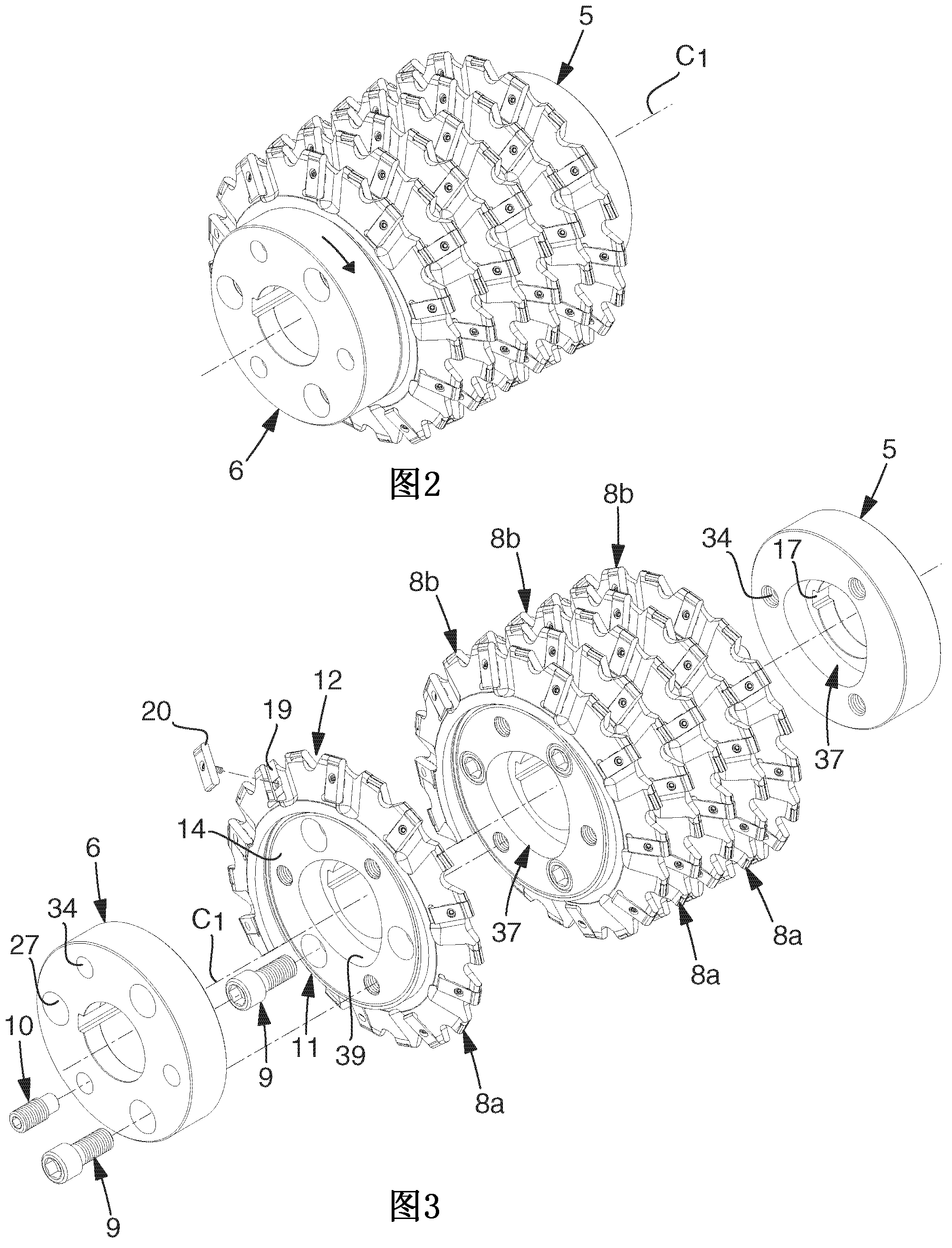

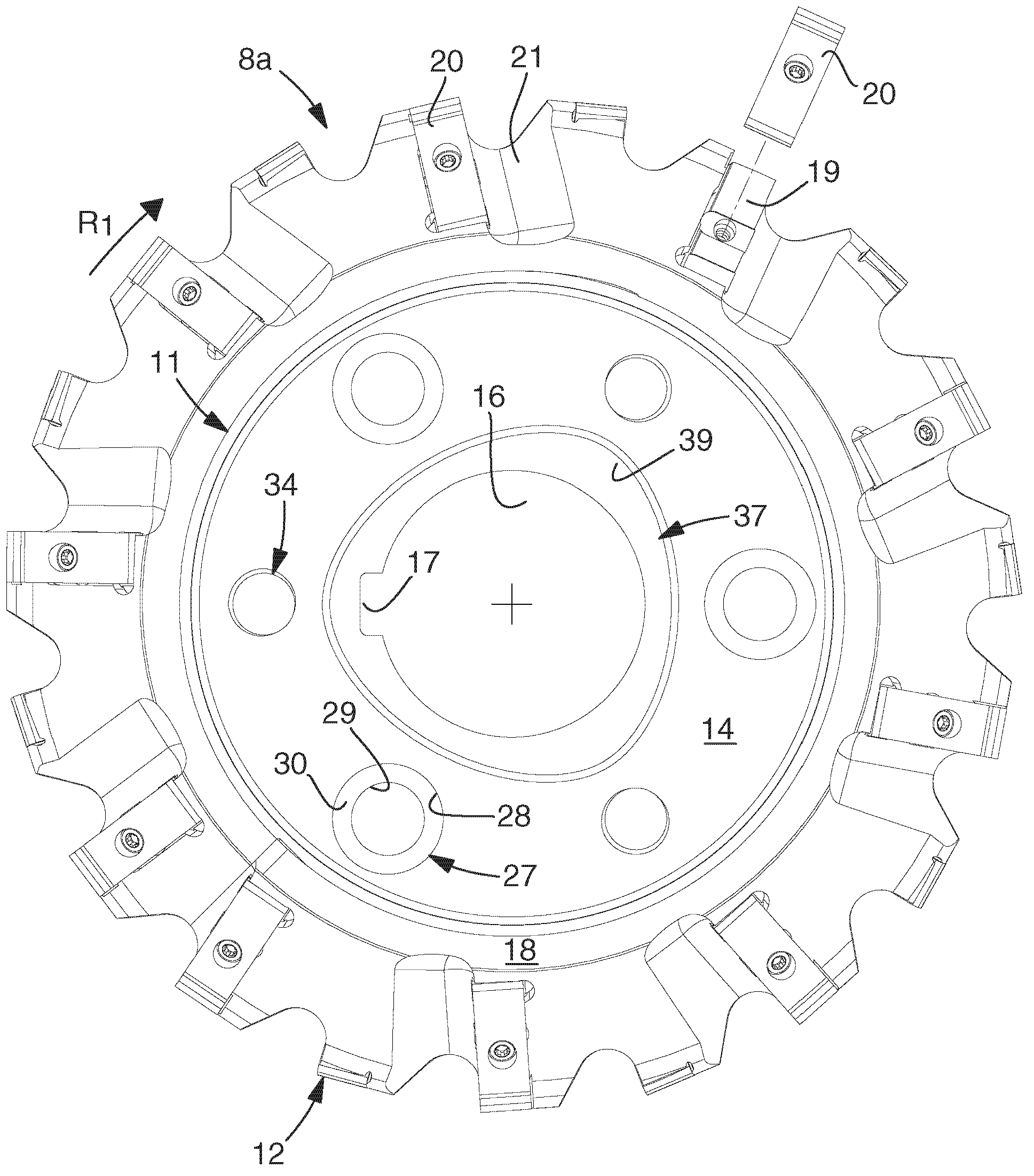

[0029] exist figure 1 , schematically shows a milling cutter 1 manufactured according to an embodiment of the invention during the machining of a workpiece W for the purpose of forming a cog (for clarity, the cog and notch are shown in the final machining state ). In other words, the invention is exemplified in the form of a segmented hob. In this example, the tool 1 is mounted on a shaft 2 whose central axis is designated C1 and which is clamped at one end in a chuck 3 and at the opposite end in a support bracket 4 . The segments which together form the milling cutter 1 are placed between a pair of end pieces, one of which is designated 5 and the other end piece is designated 6 . In order to transmit the torque from the drive shaft 2 to the tool 1, the wedge 7 is countersunk in a groove on the drive shaft and engages with an internal groove in the different segments. While the workpiece W can be turned or rotated in the direction R2 , more precisely around the center axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com