Automated positioning of wheels in tyre pressure control systems

A technology for motor vehicles and wheels, which is applied in tire measurement, vehicle parts, transportation and packaging, etc., which can solve the problems of measurement accuracy uncertainty and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

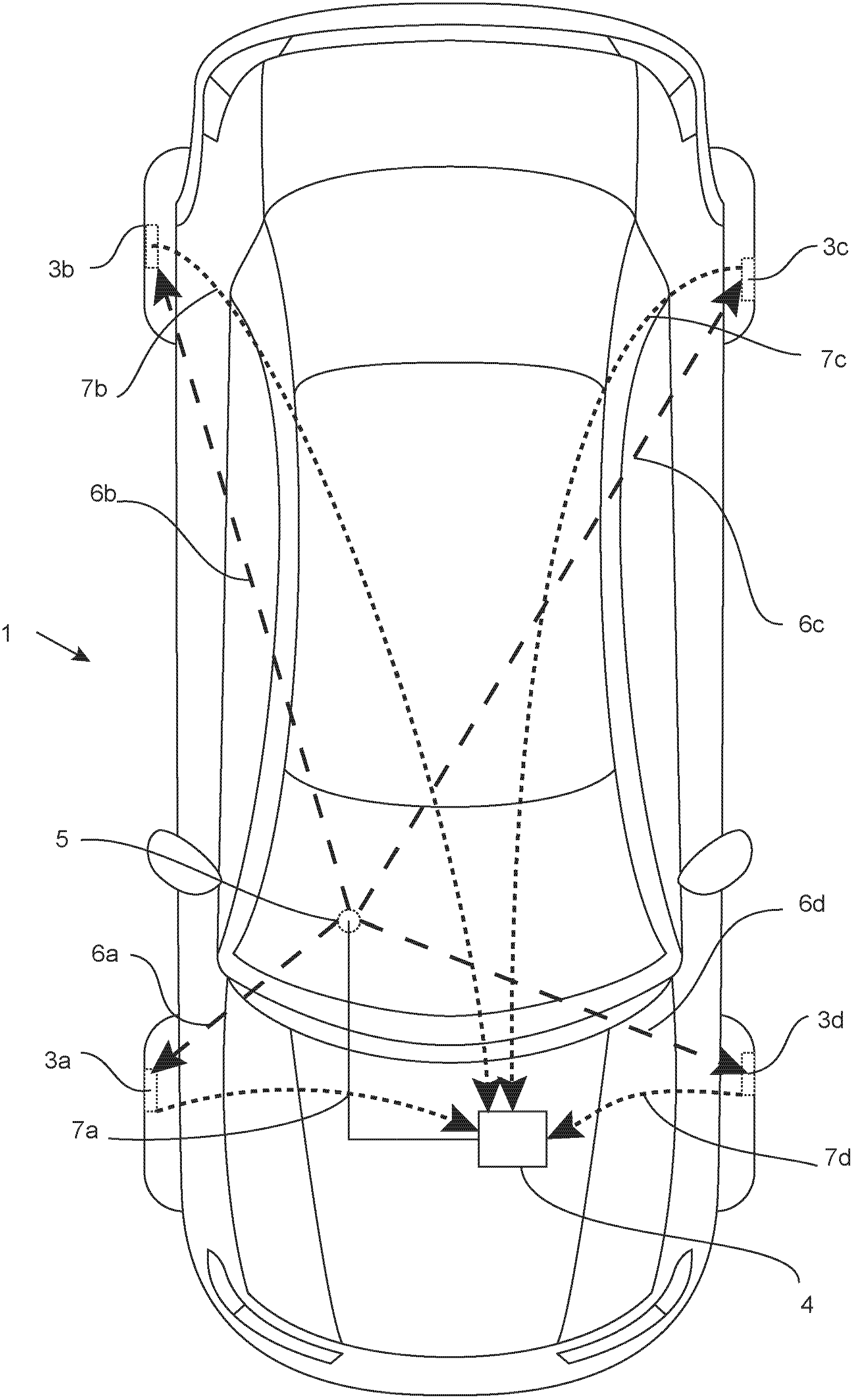

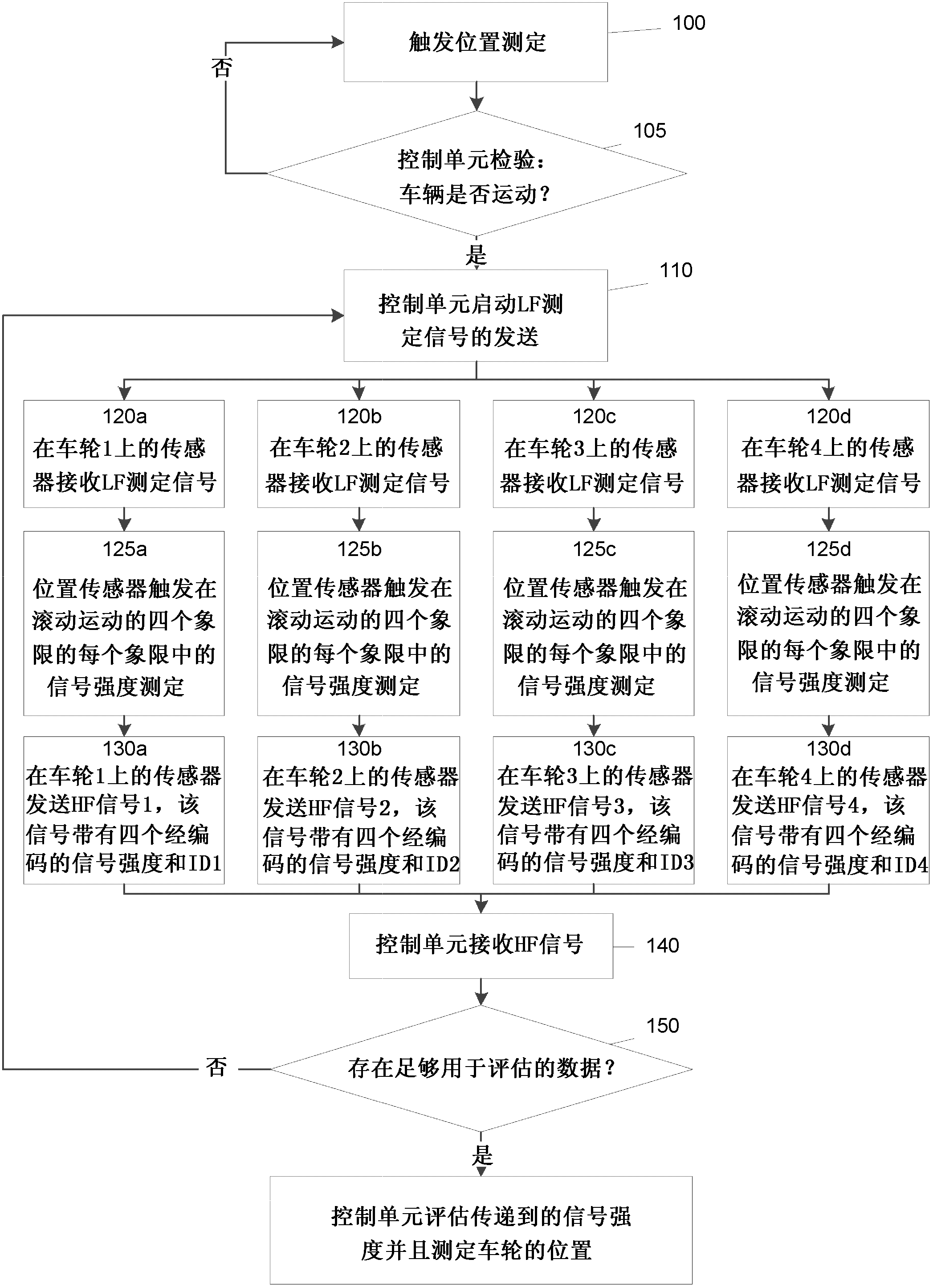

[0026] figure 1 A motor vehicle 1 is shown in , which has tire pressure sensors 3 a , 3 b , 3 c and 3 d on its wheels 2 .

[0027] A control device 4 is embodied on the motor vehicle. An antenna 5 arranged under the vehicle for radiation to the outside area is coupled to the control device 4 . The control device 4 can control the antenna 5 in order to transmit a measurement signal with a frequency of 125 kHz. In this example, the antenna is arranged below the vehicle floor with a certain radiation and is positioned decenter on the vehicle. The antenna 5 is arranged offset both to the longitudinal axis of the vehicle and to the central transverse axis of the vehicle. The antenna 5 has a different distance from each of the pressure sensors 3a, 3b, 3c and 3d. The signal paths from the antenna 5 to the sensors are shown with arrows 6a, 6b, 6c and 6d. Pressure sensors 3 a , 3 b , 3 c and 3 d have mechanisms with which radio communication with central control unit 4 can be carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com