Sensing heating overheating device for steam heat storage device

A technology of induction heating and superheating device, which is applied in the direction of steam superheating, steam generation, and superheating temperature control, etc. It can solve the problems of low accuracy of thermal deviation calculation, many explosion accidents of superheater, and large fluctuation of steam supply pressure. To achieve the effect of easy control of heating temperature, labor saving and stable air supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

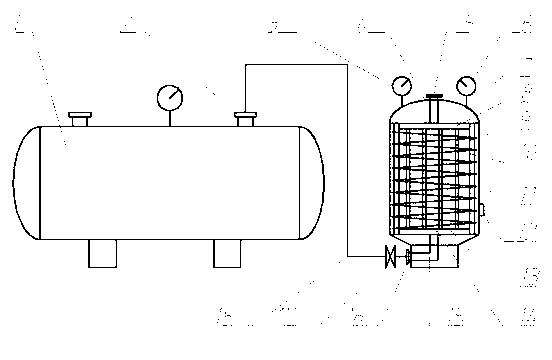

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

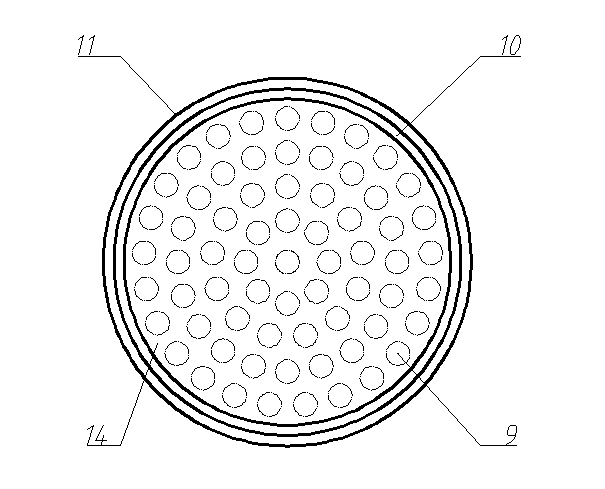

[0021] An induction heating superheating device for a steam accumulator includes a steam accumulator 1, a steam outlet 2 of the steam accumulator, a thermometer 3, a steam outlet pipe 4, a superheater steam outlet 5, a pressure gauge 6, and an induction heating superheater 7, steam collecting pan 8, induction heating tube 9, thermal layer 10, superheater outer wall 11, temperature controller 12, coil 13, steam distribution pan 14, steam inlet pipe 15, superheater steam inlet 16, steam inlet switch 17, connect the pipe 18. The induction heating superheater 7 is connected to the steam accumulator 1 through a connecting pipe 18, the connecting pipe 18 is provided with a steam inlet switch 17, and the induction heating superheater 7 is provided with a temperature gauge 3 and a pressure gauge 6.

[0022] A temperature controller 12 is installed on the outer wall 11 of the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com