Vacuum tube wall type heat absorber

A vacuum tube and heat sink technology, which is applied to heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problems of high concentrating precision requirements of heliostat field, prone to high temperature oxidation, small opening of heat sink, etc. Achieve the effect of improving energy utilization efficiency, simple structure and increasing opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

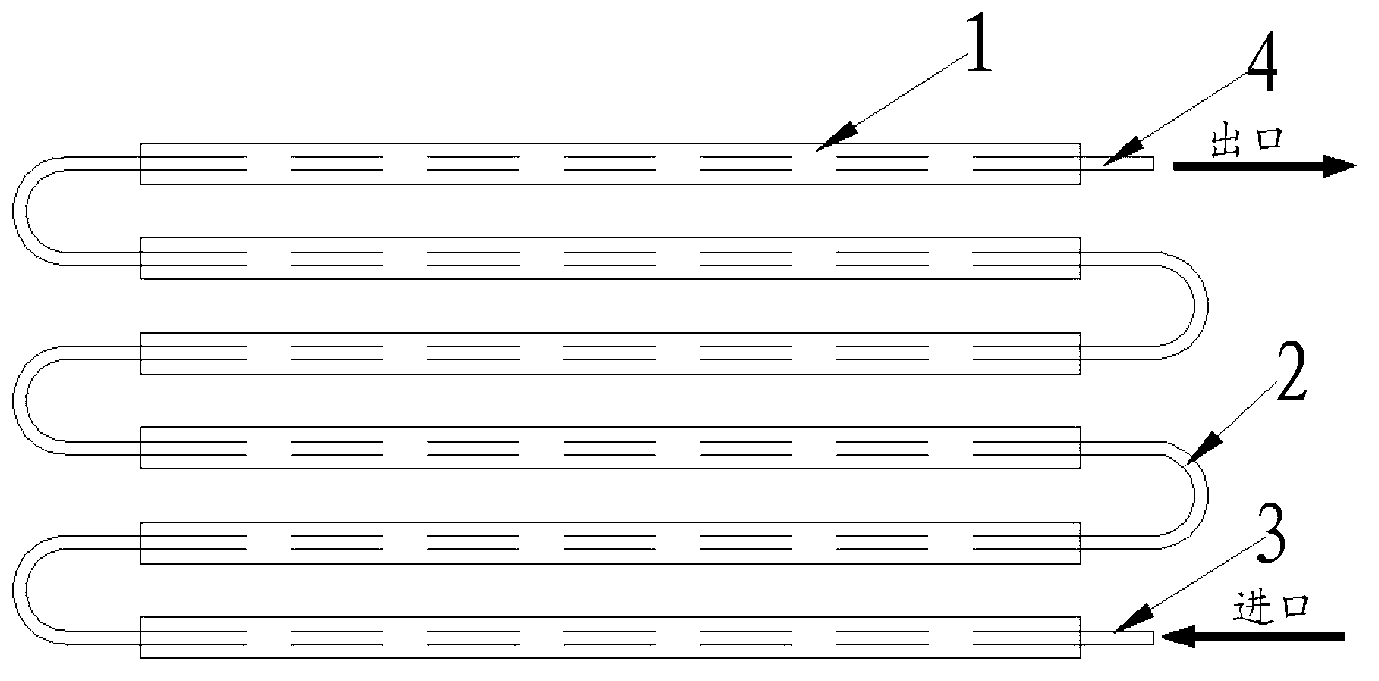

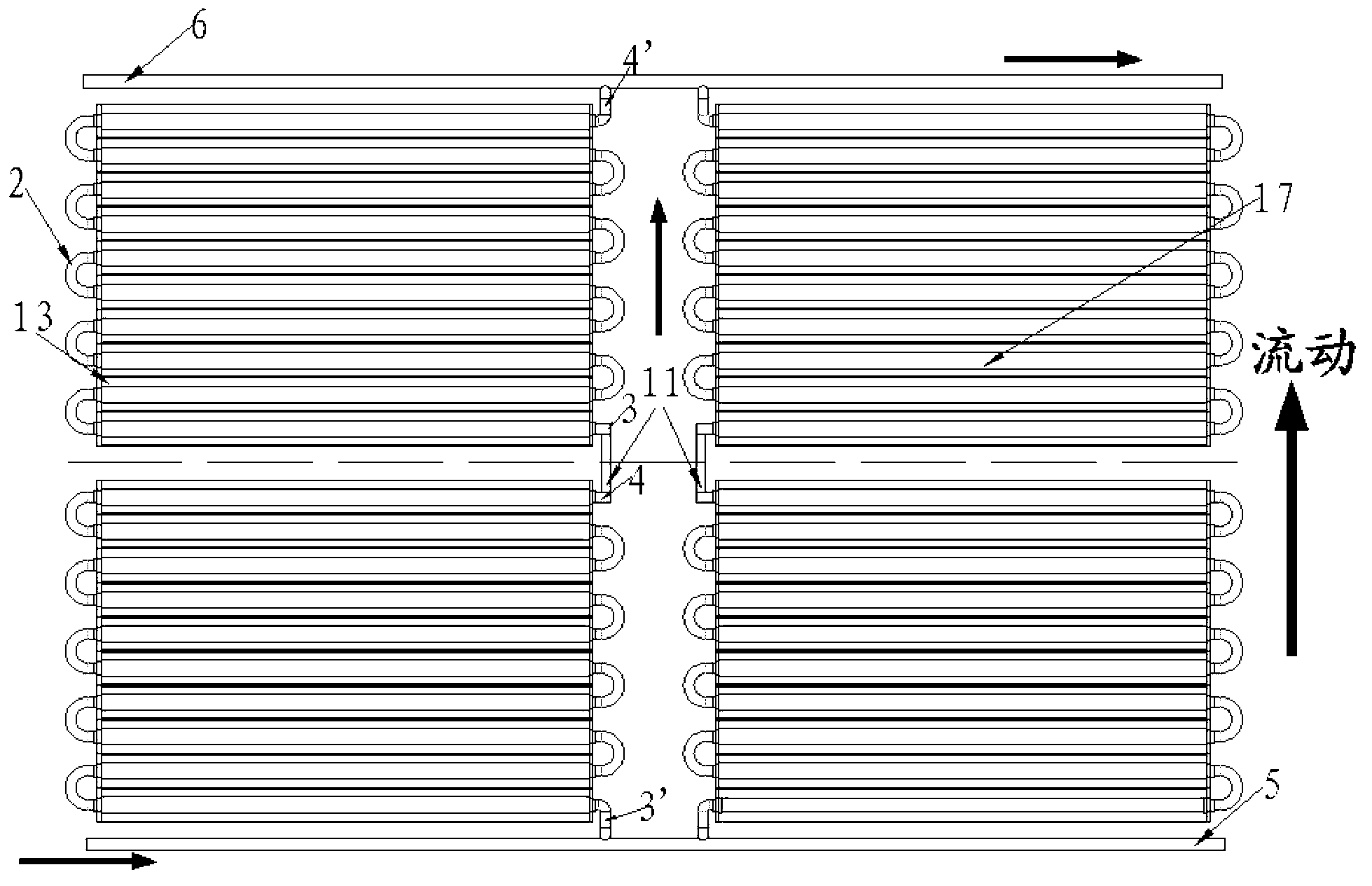

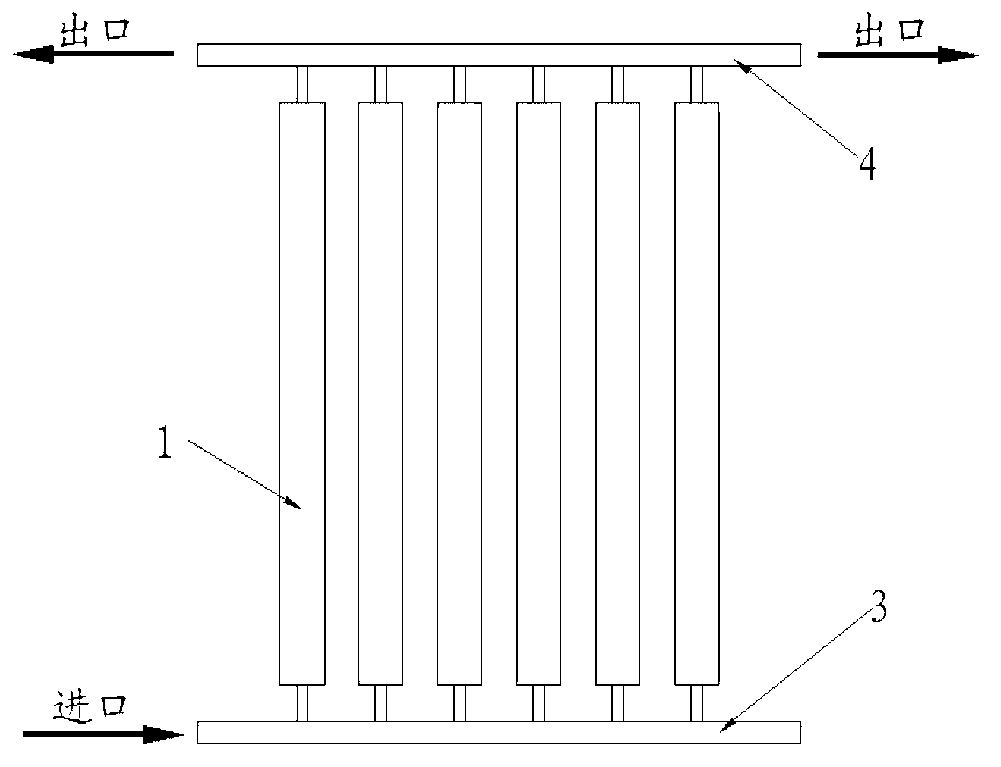

[0032] The vacuum tube wall heat absorber of the present invention is composed of series heat absorption modules 17 or parallel heat absorption modules 18 , connecting pipes 11 , inlet main pipe 5 and outlet main pipe 6 .

[0033] A plurality of the heat-absorbing modules 17, 18 are connected in series through the connecting pipeline 11, one end of the connecting pipeline 11 is welded to the inlet pipe 3 of the heat-absorbing module, and the other end of the connecting pipeline 11 is connected to the outlet pipe of the heat-absorbing module. 4 welding Unicom. The inlet main pipe 5 is the main pipeline through which the heat transfer working medium of the heat absorber flows into the heat absorber, and the inlet main pipe 5 and the heat absorption module inlet pipes 3' of the heat absorption modules 17 and 18 located at the outermost side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com