Novel material dynamic mechanics performance testing method and device thereof

A technology of dynamic mechanics and measurement methods, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as data processing errors, and achieve the effect of compact measurement system and reduction of errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

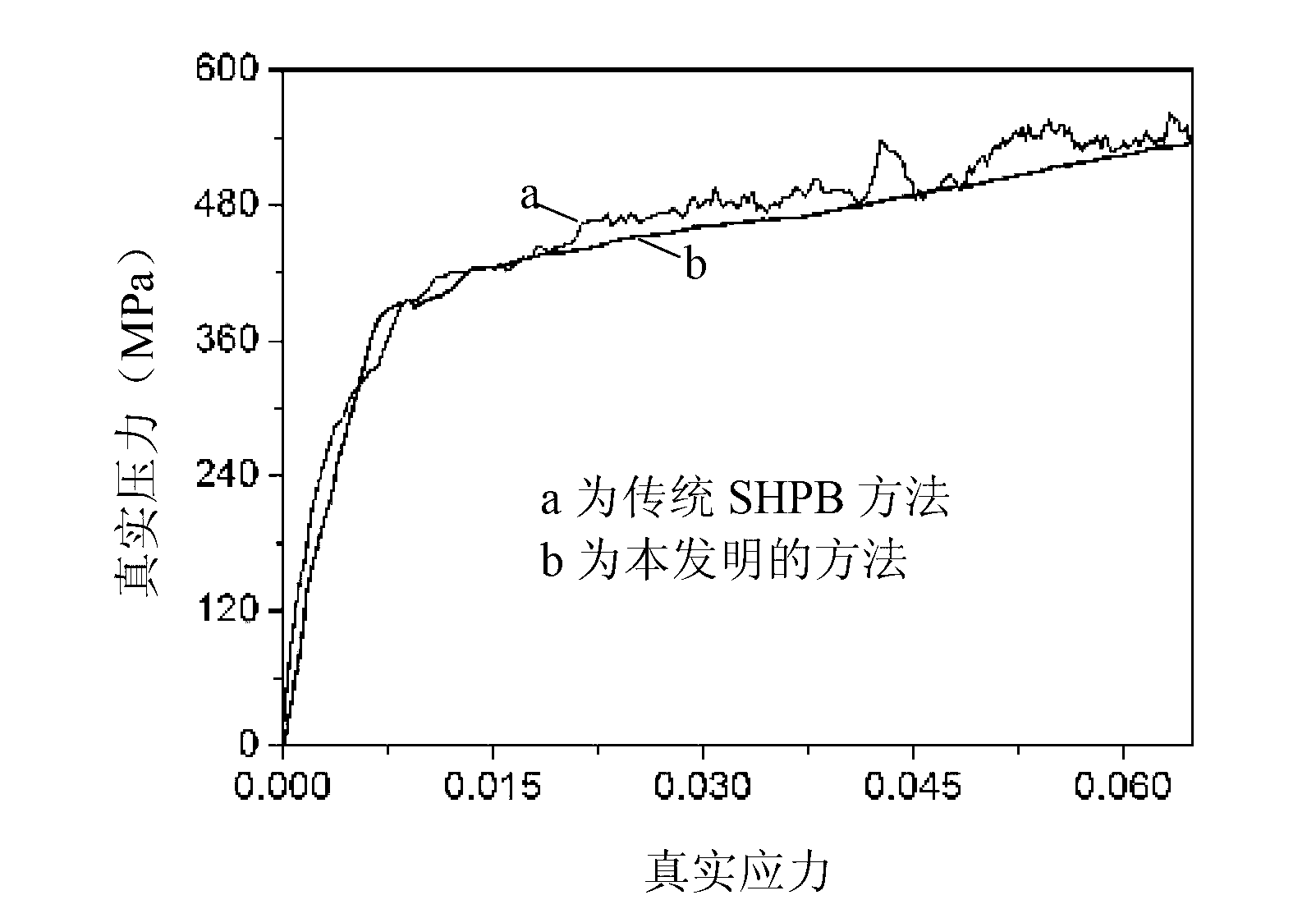

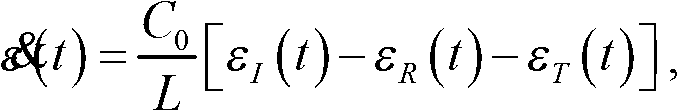

[0034] The experimental principle of the present invention is: when the stress wave propagates inside the sample, due to the effect of lateral expansion and lateral inertia, the radial velocity v of the particle will be generated R , the particle velocity is measured by a high-precision velocimeter, and the stress waveform passing through the sample is measured by a high-sensitivity pressure sensor. The stress-strain relationship of the sample is obtained by processing the data.

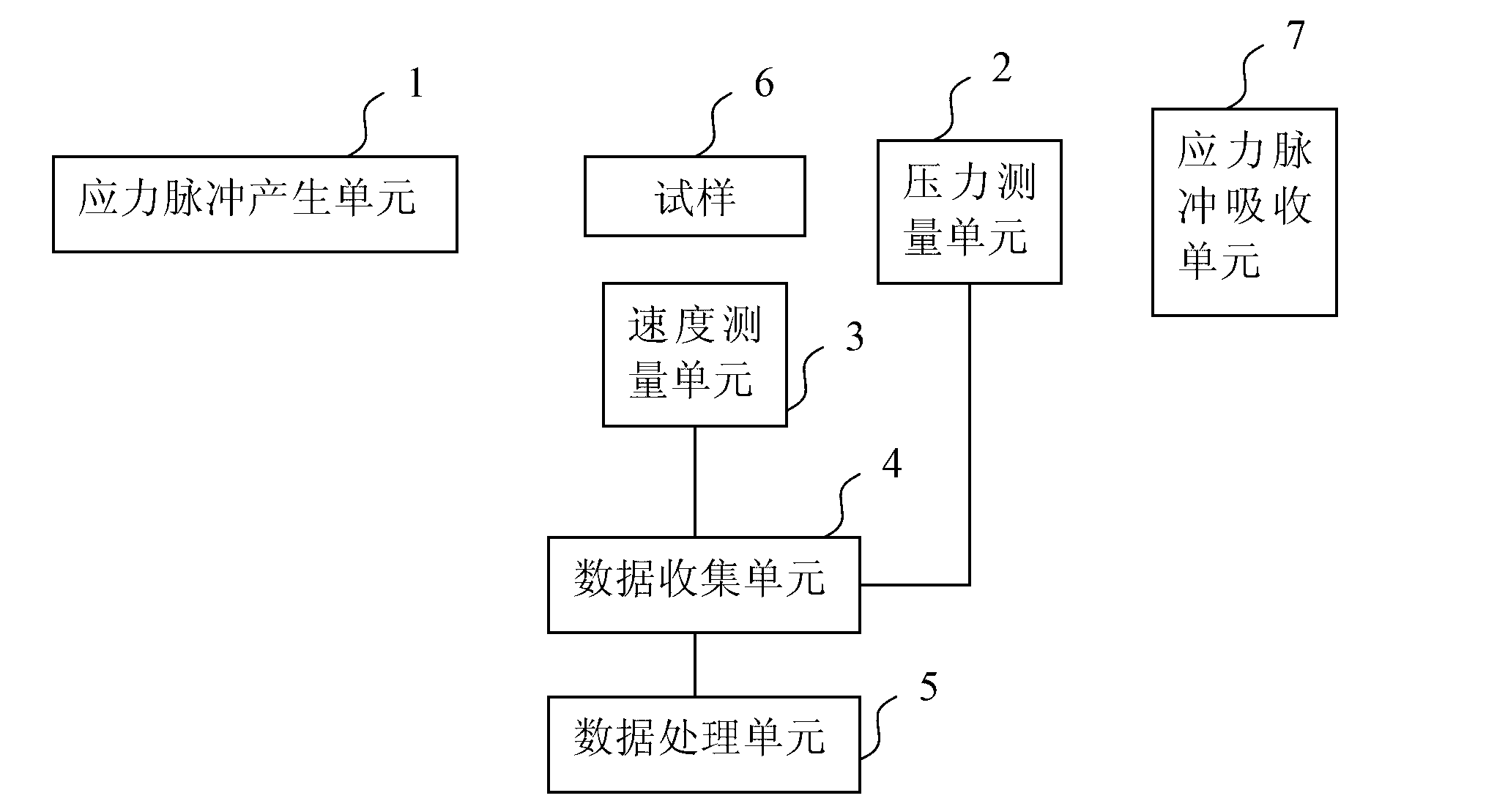

[0035] Such as figure 1 As shown, the present invention includes: a stress pulse generation unit 1 , a pressure measurement unit 2 , a velocity measurement unit 3 , a data collection unit 4 , a data processing unit 5 and a stress wave absorption unit 7 .

[0036] The stress pulse generation unit 1 is used to generate a stress pulse with predetermined intensity and pulse width, and send it to the sample 6 to be tested.

[0037] The pressure measurement unit 2 is used to measure the stress wave passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com