Pot-type insulator

A basin-type insulator and basin-body technology, which is applied to insulators, electrical components, circuits, etc., can solve the problems of uneven electric field distribution, flashover discharge of insulators, and inability to meet the requirements of high voltage levels, and achieve cost reduction and smooth slope. , Improve the effect of electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

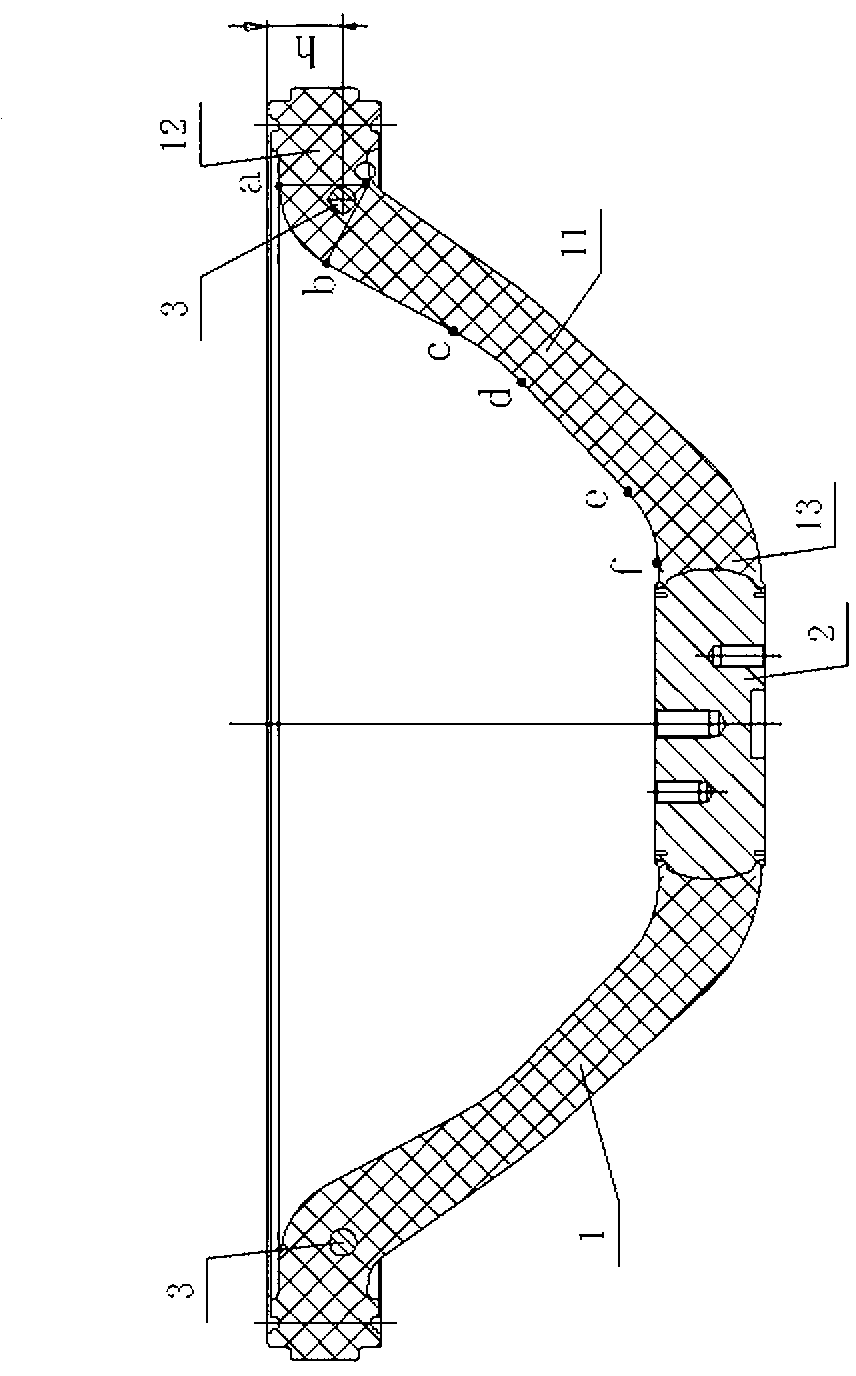

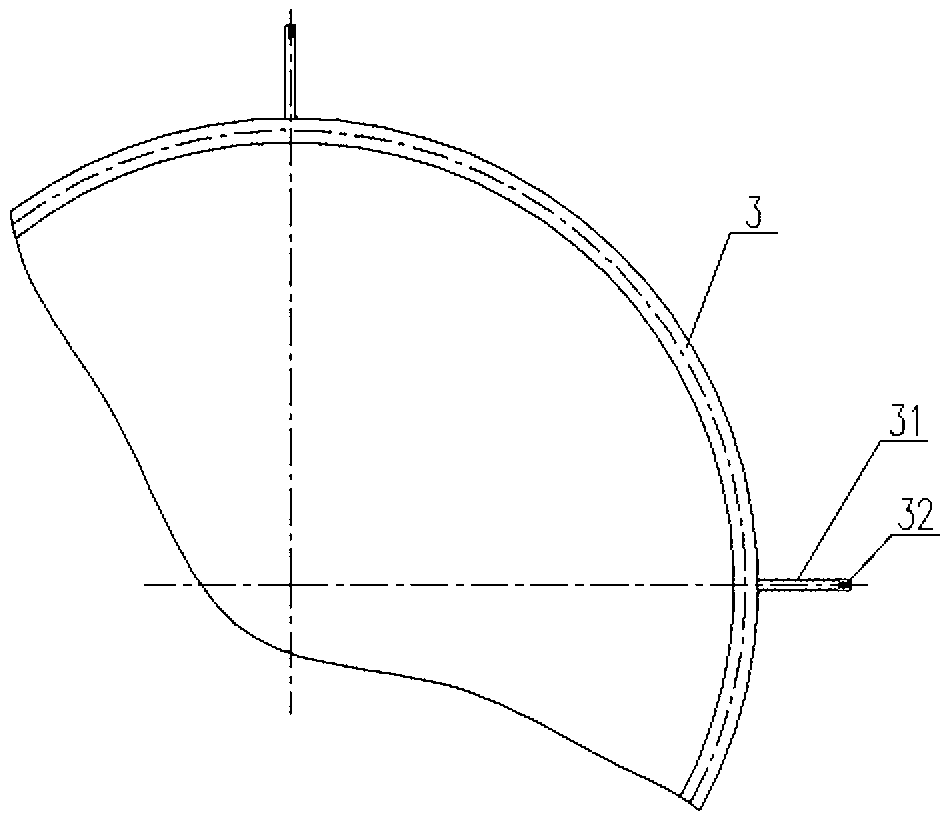

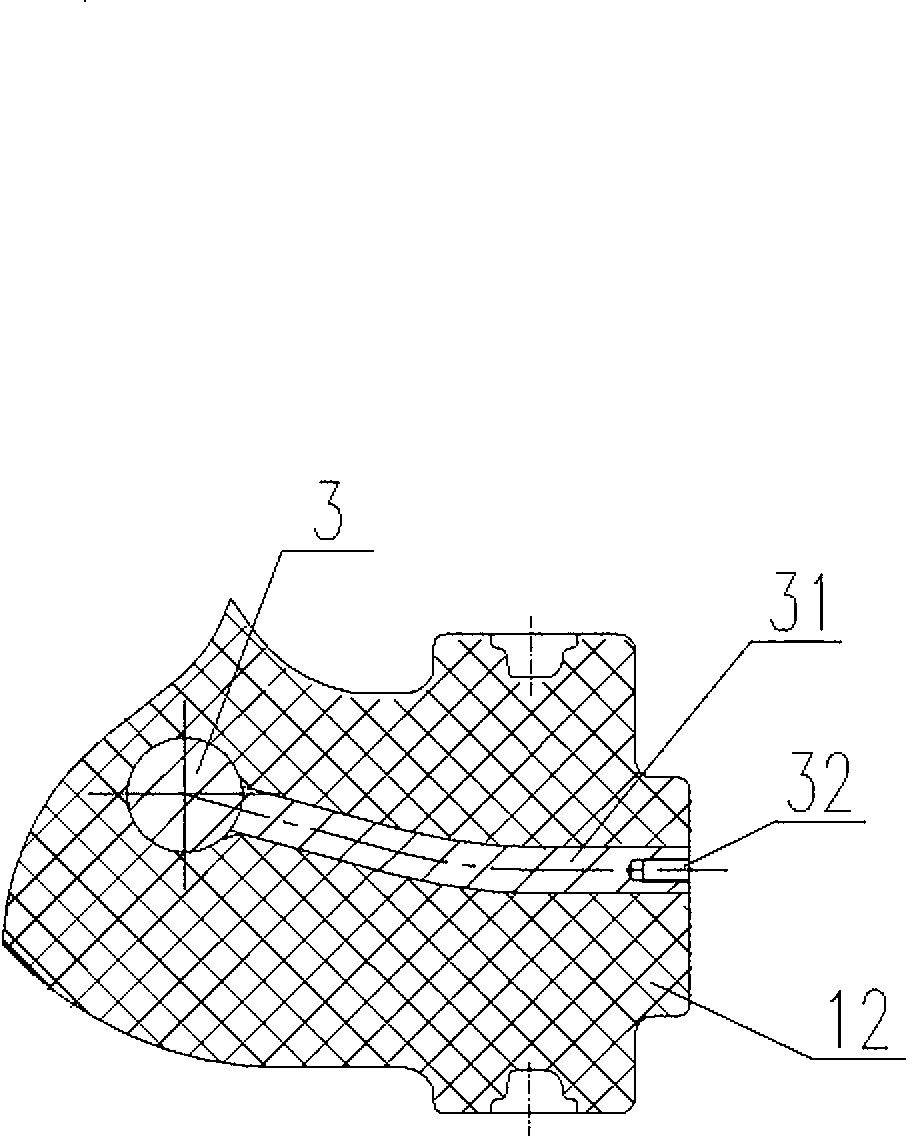

[0019] For an embodiment of the pot insulator provided by the present invention, see Figure 1-Figure 3 As shown, it includes a basin-shaped insulating casting body 1 composed of a basin bottom 13, a basin body 11 and a basin edge 12. The basin bottom 13 of the insulating casting body is provided with a central conductor 2 formed integrally with it by casting. The inner wall surface of the pot body 11 of the pouring body is connected with the corresponding surfaces of the pot edge 12 and the pot bottom 13 respectively through the corresponding tangent first arc surface segment ab and the second arc surface segment ef, and the first arc surface segment is an arc surface Section, the inner wall surface of the basin body 11 is composed of upper and lower cone sections bc, de and a transition arc surface section cd connecting the two cone sections, the two ends of the transition arc surface section cd are connected with the upper and lower cone sections The lower cone section is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com