CMOS image sensor module and manufacturing method thereof

A technology of image sensor and manufacturing method, which is applied in radiation control devices, semiconductor/solid-state device testing/measurement, etc., can solve the problems of low yield rate and high cost, and achieve low cost, stable performance, and good moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

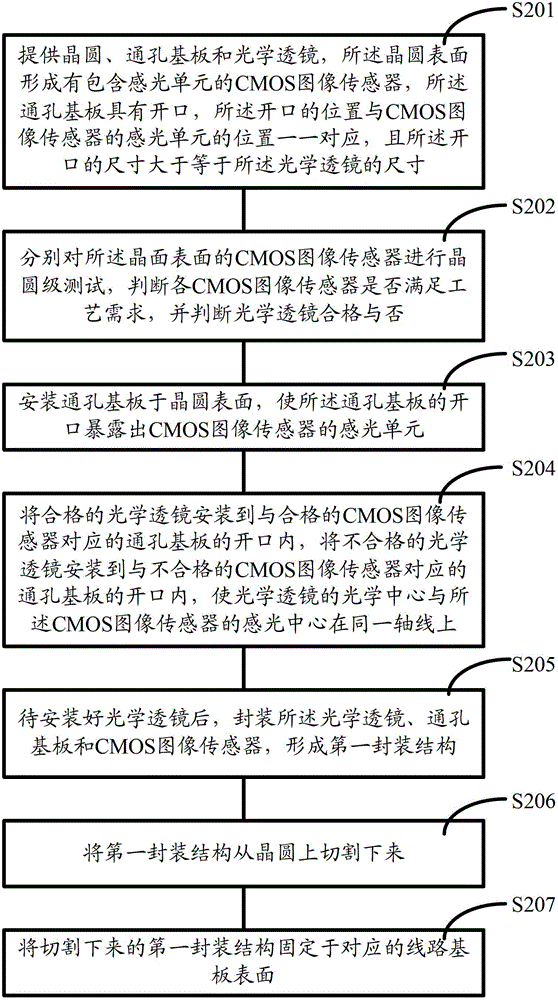

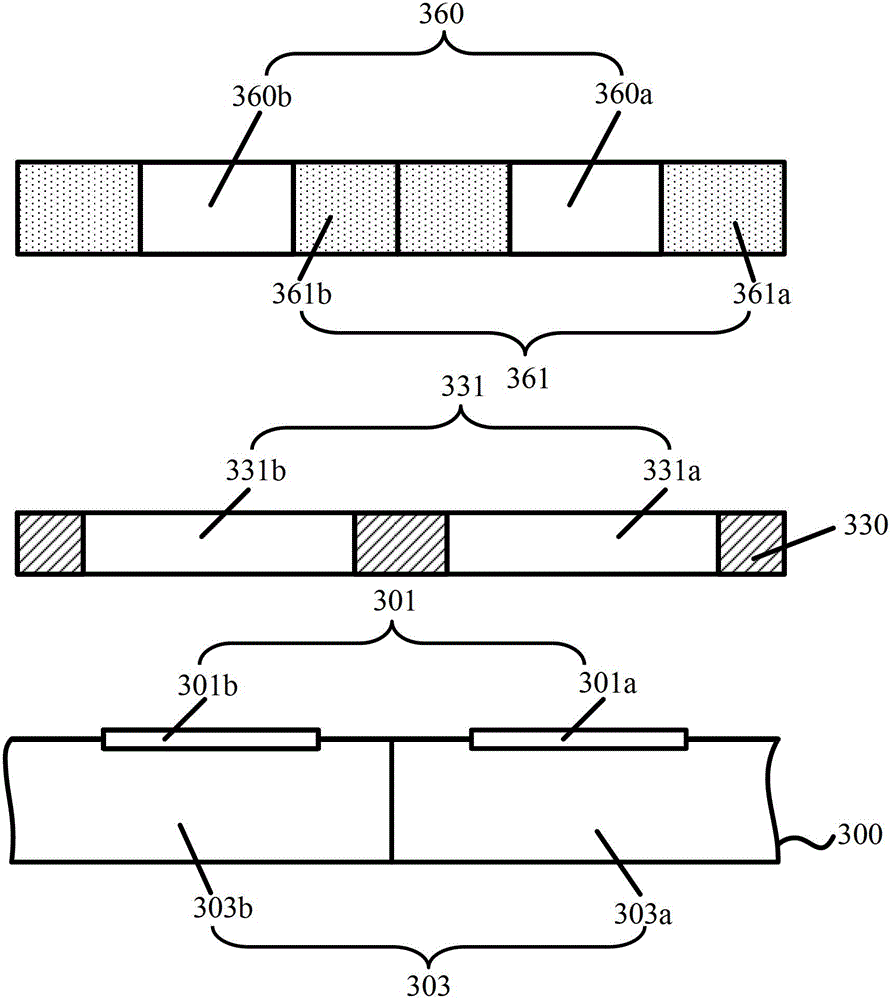

[0074] Please refer to figure 2 , the manufacturing method of the CMOS image sensor module in the first embodiment of the present invention, comprising:

[0075] Step S201, providing a wafer, a through-hole substrate, and an optical lens. A CMOS image sensor including a photosensitive unit is formed on the surface of the wafer. The through-hole substrate has an opening, and the position of the opening is the same as that of the photosensitive unit of the CMOS image sensor. The positions are in one-to-one correspondence, and the size of the opening is greater than or equal to the size of the optical lens;

[0076] Step S202, performing a wafer-level test on the CMOS image sensors on the wafer surface, judging whether each CMOS image sensor meets the process requirements, and judging whether the optical lens is qualified;

[0077] Step S203, installing a through-hole substrate on the surface of the wafer, so that the opening of the through-hole substrate exposes the photosensi...

no. 2 example

[0112]Different from the first embodiment of the present invention, in the second embodiment of the present invention, after the through-hole substrate is installed on the wafer surface to expose the photosensitive unit of the CMOS image sensor, a protective plate is formed on the surface of the through-hole substrate to protect the subsequent The CMOS image sensor in the process is protected from dust and moisture. And before installing the optical lens into the opening of the through-hole substrate, the protective plate is removed.

[0113] Please refer to Figure 7 , the manufacturing method of CMOS image sensor module in the second embodiment of the present invention, comprises:

[0114] Step S401, providing a wafer, a through-hole substrate, and an optical lens. A CMOS image sensor including a photosensitive unit is formed on the surface of the wafer. The through-hole substrate has an opening, and the position of the opening is the same as that of the photosensitive unit...

no. 3 example

[0159] Different from the first embodiment and the second embodiment of the present invention, the third embodiment of the present invention provides a CMOS image sensor module.

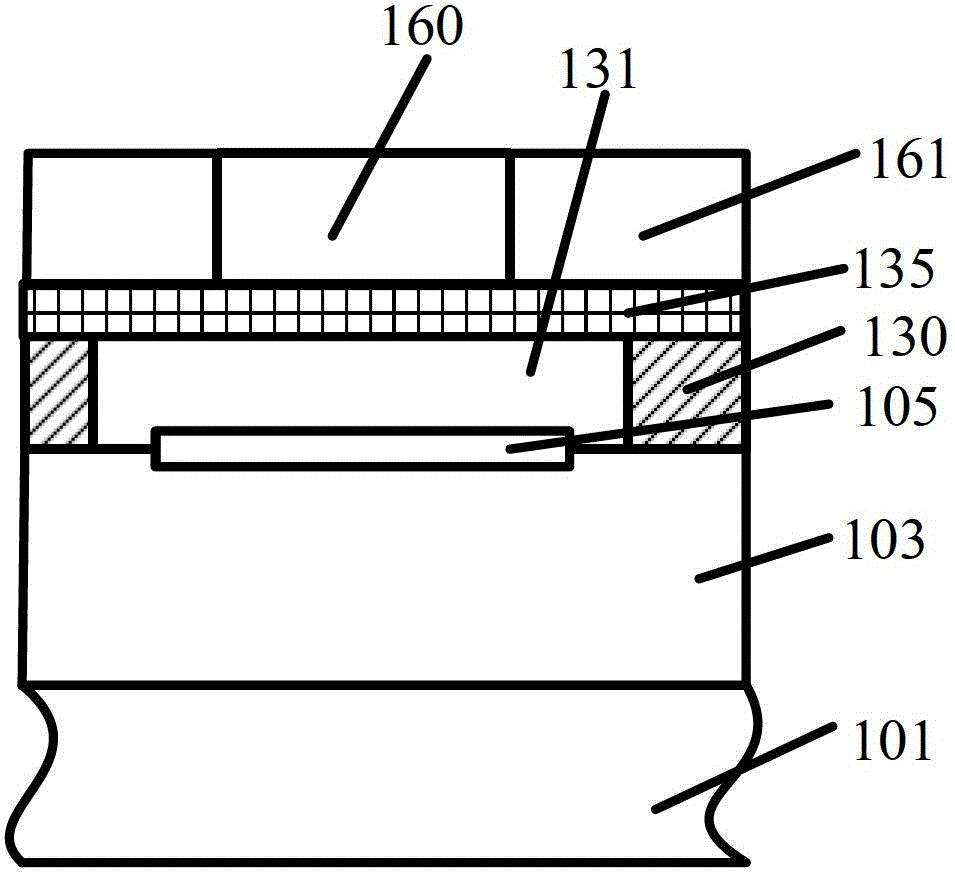

[0160] Accordingly, please refer to Figure 13 , the inventor also provides a CMOS image sensor module, including:

[0161] Circuit substrate 601;

[0162] A CMOS image sensor 603 located on the circuit substrate 601 and electrically connected to the circuit substrate 601, the CMOS image sensor 603 including a photosensitive unit 605;

[0163] An optical lens 660, the optical lens 660 is located above the CMOS image sensor 603, and the optical center of the optical lens 660 is on the same axis as the photosensitive center of the photosensitive unit 605;

[0164] The through-hole substrate 630 between the CMOS image sensor 603 and the optical lens 660, the through-hole substrate 630 has an opening 631, and the light of the optical lens 660 is irradiated to the photosensitive unit of the CMOS image s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com