Screw-thread-driven rotary-linear ultrasonic motor using columnar stator high-order bending vibration mode

A linear ultrasonic motor, bending vibration technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of small output torque, achieve performance improvement, work High efficiency and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

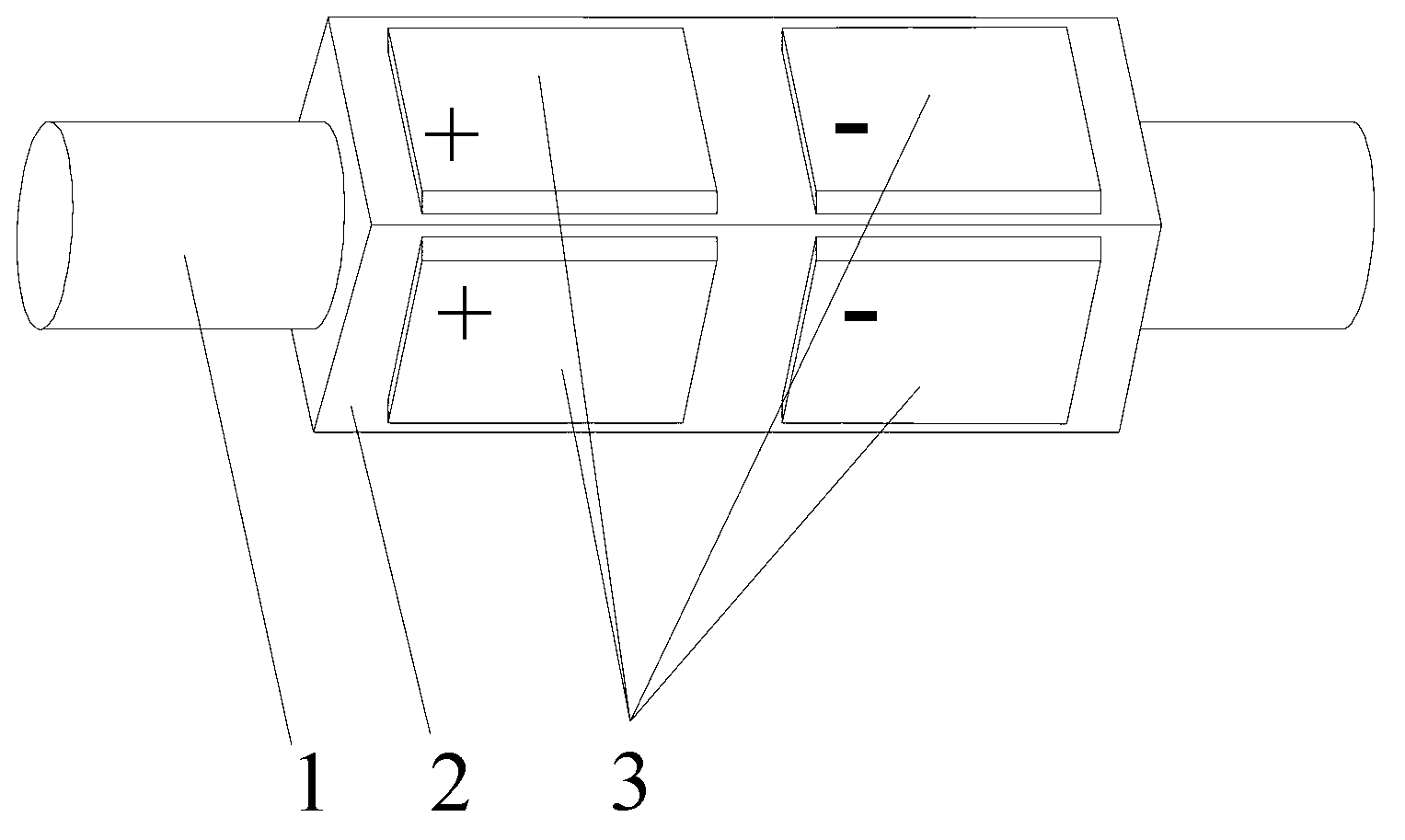

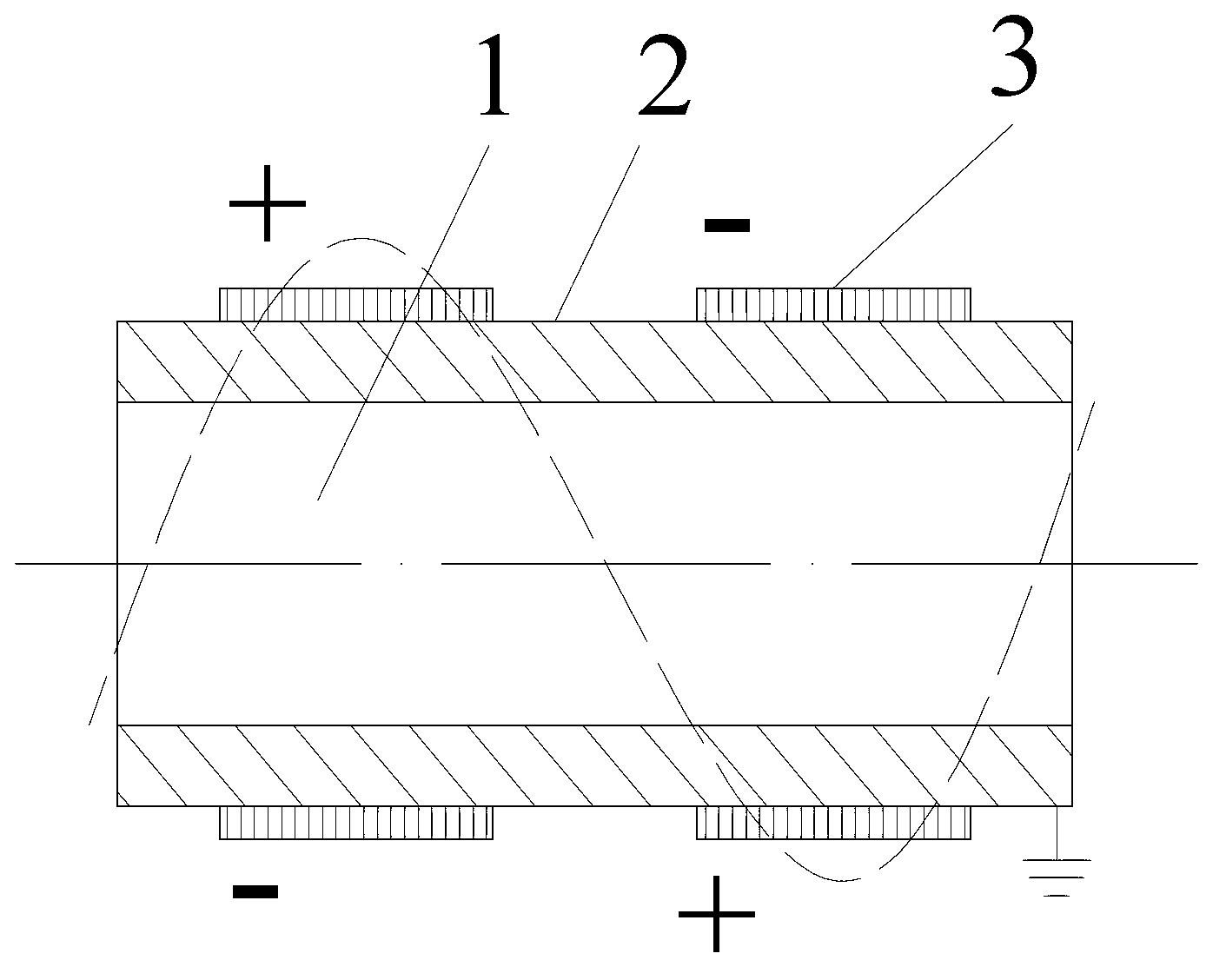

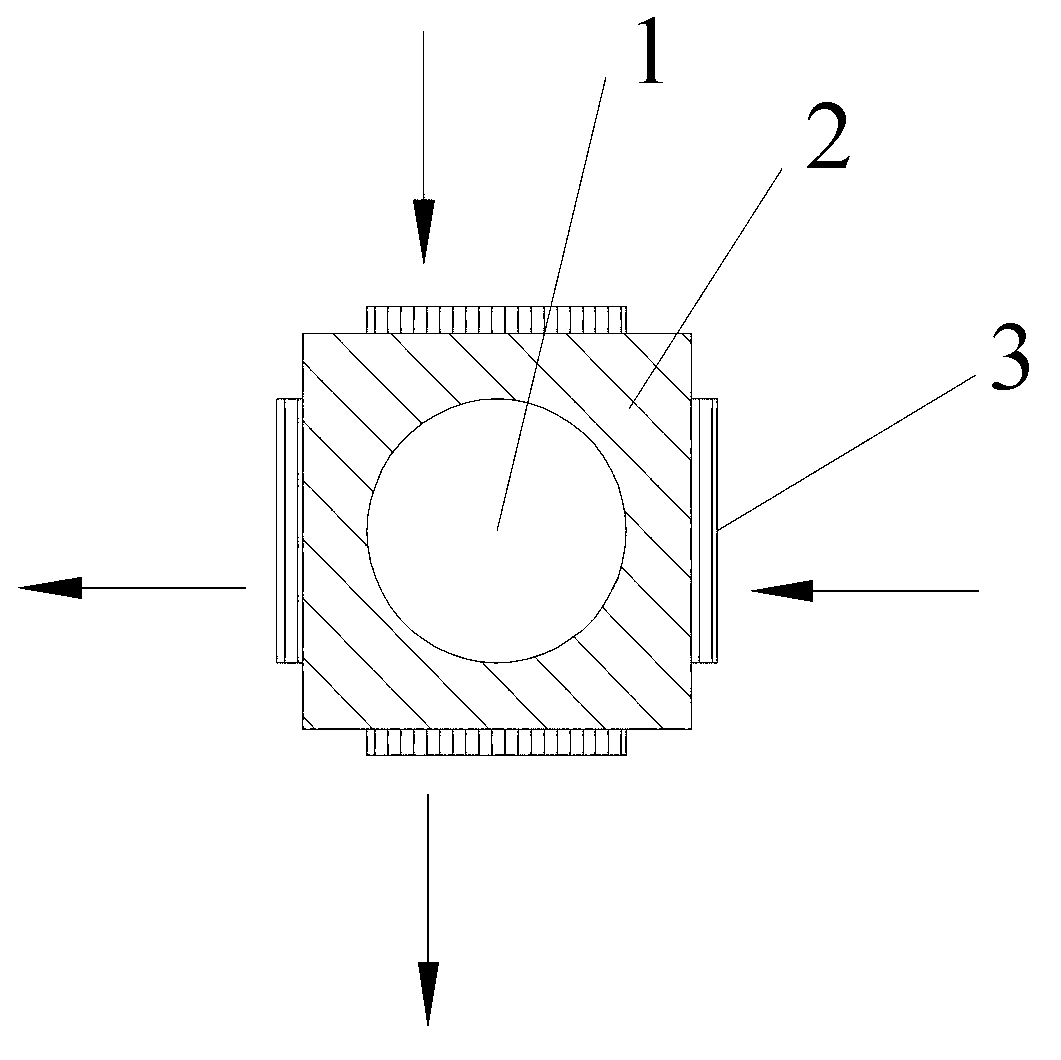

[0053] Specific implementation mode one: the following combination Figure 1 to Figure 7 This embodiment is described. The thread-driven rotary linear ultrasonic motor using the high-order bending vibration mode of the cylindrical stator described in this embodiment includes a threaded output shaft 1, a metal tube elastic sleeve 2 and m groups of piezoelectric ceramic sheets 3, m is a positive integer,

[0054] The metal tube elastic sleeve 2 is sleeved on the outer surface of the threaded output shaft 1, and is connected with the threaded output shaft 1 through a thread pair. The outer contour of the cross section of the metal tube elastic sleeve 2 is a regular n-gon, and the value of n is is an integer multiple of 4,

[0055] On the outer surface of the metal tube elastic sleeve 2, m groups of piezoelectric ceramic sheets 3 are evenly distributed in the axial direction, each group of piezoelectric ceramic sheets 3 is composed of n piezoelectric ceramic sheets, and each grou...

specific Embodiment approach 2

[0061] Specific implementation mode two: the following combination Figure 8 to Figure 12 This embodiment is described. The thread-driven rotary linear ultrasonic motor using the high-order bending vibration mode of the cylindrical stator described in this embodiment includes a threaded output shaft 1, a metal tube elastic sleeve 2 and m groups of piezoelectric ceramic sheets 3, m is a positive integer,

[0062] The metal tube elastic sleeve 2 is sleeved on the outer surface of the threaded output shaft 1, and is connected with the threaded output shaft 1 through a thread pair. The outer contour of the cross section of the metal tube elastic sleeve 2 is composed of a circular arc and two straight lines. A shape composed of arcs greater than or equal to one-half of the circumference, and two straight line segments of equal length and perpendicular to each other;

[0063] On the outer surface of the metal tube elastic sleeve 2, m groups of piezoelectric ceramic sheets 3 are eve...

specific Embodiment approach 3

[0071] Specific implementation mode three: the following combination figure 2 and Image 6 This embodiment is described. This embodiment is a further description of Embodiment 1 or 2. The m groups of piezoelectric ceramic sheets 3 are respectively located at the center amplitudes of m amplitudes of the m-order bending vibration of the metal tube elastic sleeve 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com