Device and method for transferring rod-like product

A kind of product and rod-shaped technology, which is applied in the field of tobacco processing equipment, can solve the problems of high sealing requirements, adjustment time, and affecting the quality of the outer surface of cigarettes, and achieve the effect of improving the end of the filament and reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

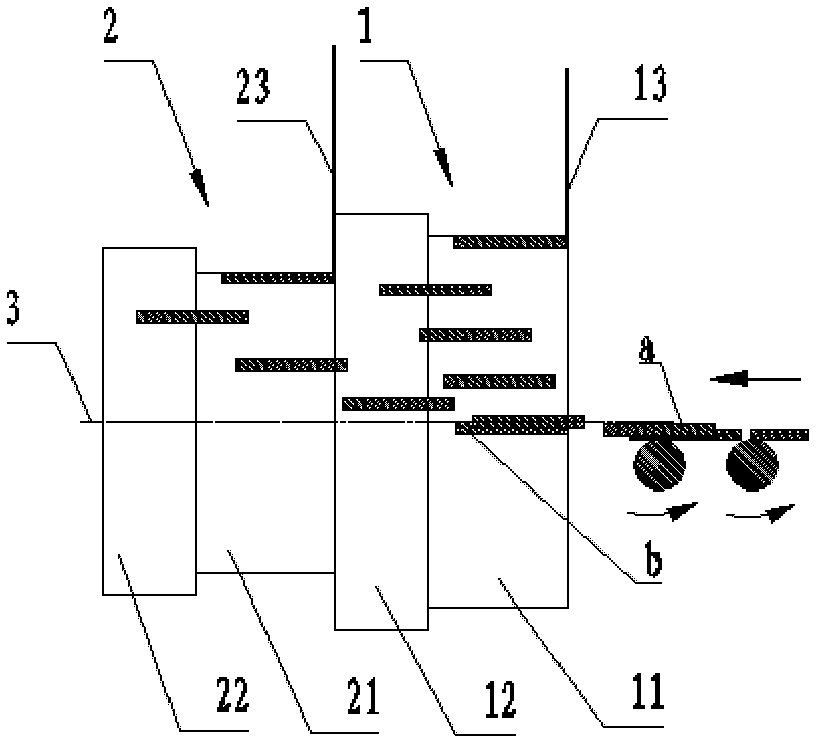

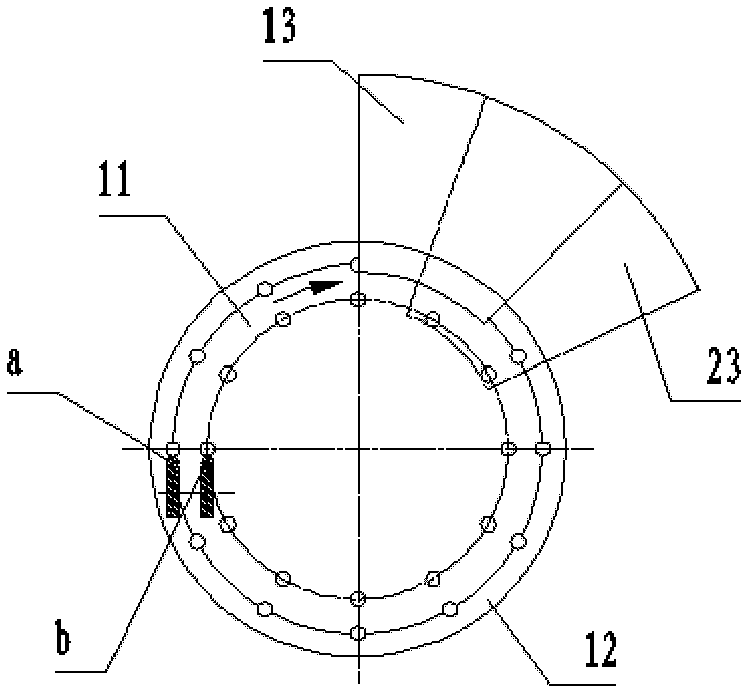

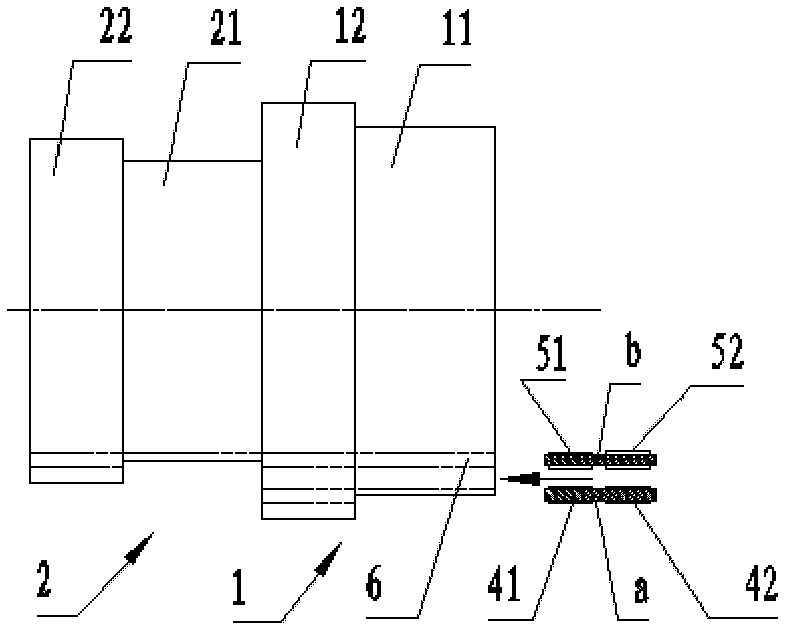

[0047] Such as Figure 1 to Figure 3 As shown, the device for transferring rod-shaped products of the present invention includes two pairs of cam smoke pulling wheels and a transmission roller, and the two pairs of cam smoke pulling wheels are arranged on the front side of the transmission roller;

[0048] The conveying roller comprises two roller bodies 1 and 2 with different diameters, the front roller body 1 comprises the first roller body 11 and the second roller body 12, and the rear roller body 2 comprises the third roller body 21 and the fourth roller body 22; The roller bodies 11, 12, 21, 22 are connected sequentially; the diameters of the first roller body 11 and the third roller body 21 are different;

[0049] The front roller body 1 and the rear roller body 2 have a common axis of rotation 3 around which the two roller bodies 1, 2 rotate;

[0050] The front ends of the first roller body 11 and the third roller body 21 are respectively provided with positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com