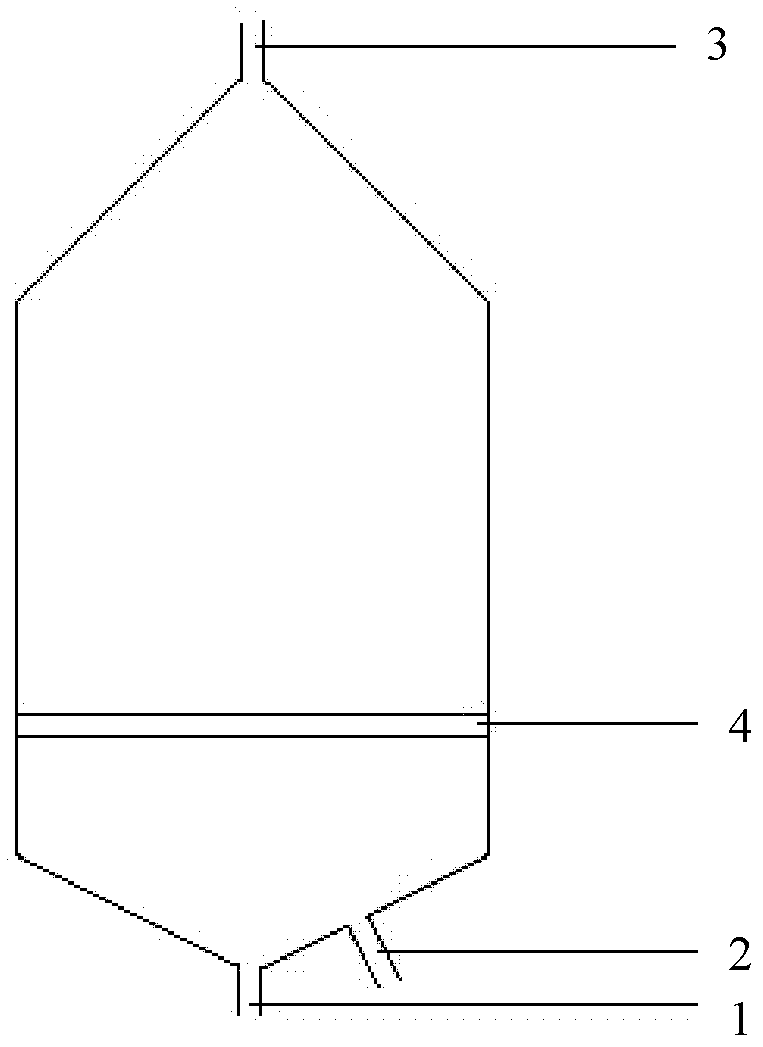

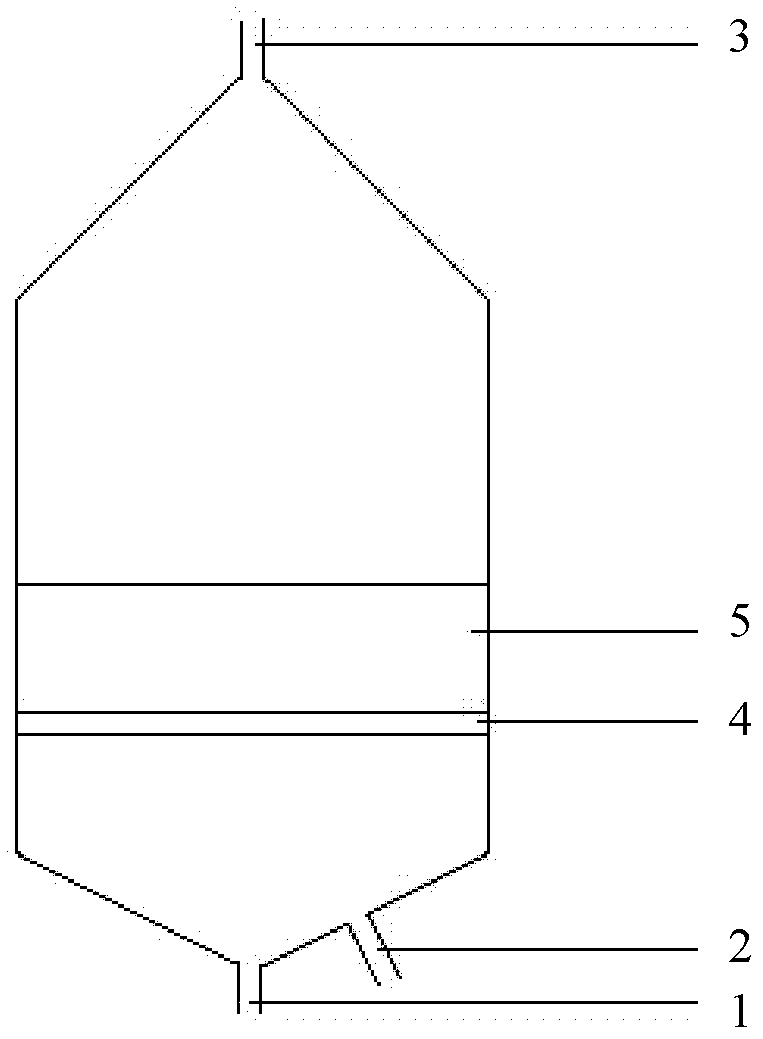

Gravity-type automatic back-flushing filter apparatus

A backwash filtration and automatic technology, which is applied in the direction of filtration separation, fixed filter elements, chemical instruments and methods, etc., can solve problems such as reduced water flow, affecting filtration quality, and filter layer failure, so as to prolong service life and improve Filtration quality, low cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment is used to illustrate the gravity automatic backwash filter device provided by the present invention and its preparation method and application.

[0043] Mix 100 parts by weight of coated silica sand (average particle size 300 μm, sphericity 0.85) with 10 parts by weight epoxy resin binder to obtain the first mixture, and lay it in a cylindrical mold with an inner diameter of 0.15 m to obtain The first mixture layer (for forming the filter layer), laying a thickness of 5.2mm;

[0044] 100 parts by weight of coated silica sand (average particle diameter 800 μm, sphericity 0.7) and 10 parts by weight of epoxy resin binder are mixed to obtain a second mixture, and the second mixture is laid on the above-mentioned first mixture layer , to obtain the second mixture layer (for forming the water-permeable support body layer), the paving thickness is 8.5mm, and when laying, the aperture of the second mixture layer is gradually reduced from top to bottom along th...

Embodiment 2

[0049] This embodiment is used to illustrate the gravity automatic backwash filter device provided by the present invention and its preparation method and application.

[0050] Mix 100 parts by weight of coated silica sand (average particle size 100 μm, sphericity 0.85) with 5 parts by weight of epoxy resin binder to obtain the first mixture, and lay it in a cylindrical mold with an inner diameter of 0.15 m to obtain The first mixture layer (for forming the filter layer), laying a thickness of 2.2mm;

[0051] 100 parts by weight of coated silica sand (average particle size 200 μm, sphericity 0.7) and 4 parts by weight of epoxy resin binder are mixed to obtain a second mixture, and the second mixture is laid on the above-mentioned first mixture layer , to obtain the second mixture layer (for forming the water-permeable support body layer), the laying thickness is 22mm, and when laying, the aperture of the second mixture layer is gradually reduced from top to bottom along the th...

Embodiment 3

[0056] This embodiment is used to illustrate the gravity automatic backwash filter device provided by the present invention and its preparation method and application.

[0057] Mix 100 parts by weight of coated silica sand (average particle size 200 μm, sphericity 0.85) with 5 parts by weight of epoxy resin binder to obtain the first mixture, and lay it in a cylindrical mold with an inner diameter of 0.15 m to obtain The first mixture layer (for forming the filter layer), laying a thickness of 3.2mm;

[0058] 100 parts by weight of coated silica sand (average particle diameter 500 μm, sphericity 0.7) and 8 parts by weight of epoxy resin binder are mixed to obtain a second mixture, and the second mixture is laid on the above-mentioned first mixture layer , obtaining the second mixture layer (for forming the water-permeable support body layer), the laying thickness is 12mm, and when laying, the aperture of the second mixture layer is gradually reduced from top to bottom along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com