Preparation method for super hydrophobic protective film on surface of high strength aluminum alloy

An aluminum alloy surface, super-hydrophobic technology, applied to the surface coating liquid device, special surface, metal material coating process, etc., to achieve the effect of simple process, convenient operation, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

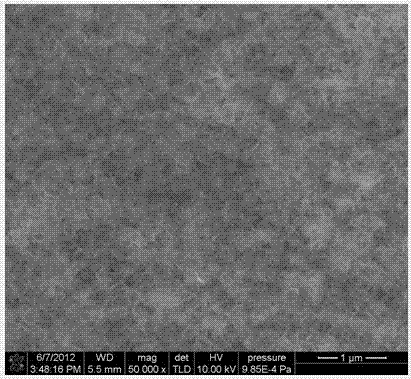

Image

Examples

Embodiment 1

[0022] The 2024 high-strength aluminum alloy workpiece with a clean surface is subjected to the following treatments in sequence:

[0023] ① Hydrothermal film formation: Immerse the clean high-strength aluminum alloy workpiece in a reaction kettle filled with 0.001mol / L cerium nitrate aqueous solution, seal the reaction kettle and keep it in an oven at 130°C for 3 hours, then naturally cool to room temperature, Take out the workpiece and dry it;

[0024] ② Hydrophobic treatment of the film layer: soak the high-strength aluminum alloy workpiece after hydrothermal film formation in step ① in the hydrophobic treatment solution at room temperature for 10 hours, take it out and dry it at 85°C for 1 hour to obtain the high-strength aluminum alloy surface Superhydrophobic protective film.

[0025] The hydrophobic treatment solution is a solution obtained by mixing dodecafluoroheptylpropyltrimethoxysilane and absolute ethanol at a volume ratio of 1:100 and magnetic stirring for 2 hou...

Embodiment 2

[0031] The 2024 high-strength aluminum alloy workpiece with a clean surface is subjected to the following treatments in sequence:

[0032] ① Hydrothermal film formation: Immerse the clean high-strength aluminum alloy workpiece in a reaction kettle filled with 0.0005mol / L samarium nitrate aqueous solution, seal the reaction kettle and keep it in an oven at 160°C for 2 hours, then naturally cool to room temperature, Take out the workpiece and dry it;

[0033] ② Hydrophobic treatment of the film layer: soak the high-strength aluminum alloy workpiece after hydrothermal film formation in step ① in the hydrophobic treatment solution at room temperature for 6 hours, take it out and dry it at 90°C for 0.5 hour to obtain the high-strength aluminum alloy surface Superhydrophobic protective film.

[0034] The hydrophobic treatment solution is a solution obtained by mixing dodecafluoroheptylpropyltrimethoxysilane and absolute ethanol at a volume ratio of 1:80 and magnetic stirring for 1 ...

Embodiment 3

[0037] The surface-cleaned 7075 high-strength aluminum alloy workpiece is subjected to the following treatments in sequence:

[0038] ① Hydrothermal film formation: Immerse the clean high-strength aluminum alloy workpiece in a reaction kettle filled with 0.001mol / L lanthanum nitrate aqueous solution, seal the reaction kettle and keep it in an oven at 120°C for 5 hours, then naturally cool to room temperature, Take out the workpiece and dry it;

[0039] ② Hydrophobic treatment of the film layer: soak the high-strength aluminum alloy workpiece after hydrothermal film formation in step ① in the hydrophobic treatment solution at room temperature for 12 hours, take it out and dry it at 80°C for 1 hour to obtain the high-strength aluminum alloy surface Superhydrophobic protective film.

[0040] The hydrophobic treatment solution is a solution obtained by mixing dodecafluoroheptylpropyltrimethoxysilane and absolute ethanol at a volume ratio of 1:120 and magnetic stirring for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com