Sn-Cu-based environment-friendly solder containing Zr and preparation method thereof

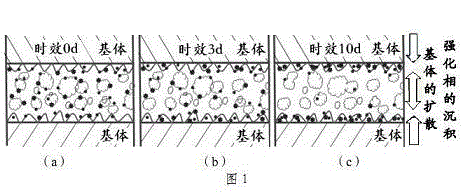

A sn-cu, environmentally friendly technology, applied in the field of tin solder alloys, can solve problems such as poor mechanical properties, achieve the effect of improving mechanical properties and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of a Sn-Cu-based environment-friendly solder that adds Zr, the steps of the preparation method are as follows:

[0020] a): Tin with a purity of 99.95%, copper with a purity of 99.95%, and zinc with a purity of 99.95% are heated to 1300°C in a vacuum melting furnace under the protection of argon to melt, while stirring, and then cooled to room temperature with the furnace , to obtain tin-copper-zinc alloy;

[0021] b): Heating the tin-copper-zinc alloy obtained in step a) to 500°C in an argon-protected vacuum furnace, then adding zirconium with a purity of 99.95%, keeping it for 3 hours and then cooling to room temperature with the furnace to obtain Zr-added Sn - Cu-based environmentally friendly solder.

[0022] The content of each component is shown in Table 1.

Embodiment 2

[0024] A preparation method of a Sn-Cu-based environment-friendly solder that adds Zr, the steps of the preparation method are as follows:

[0025] a): Tin with a purity of 99.95%, copper with a purity of 99.95%, and zinc with a purity of 99.95% are heated to 1350°C in a vacuum melting furnace under the protection of argon to melt, while stirring, and then cooled to room temperature with the furnace , to obtain tin-copper-zinc alloy;

[0026] b): Heating the tin-copper-zinc alloy obtained in step a) to 550°C in an argon-protected vacuum furnace, then adding zirconium with a purity of 99.95%, keeping it for 4 hours and then cooling to room temperature with the furnace to obtain Zr-added Sn - Cu-based environmentally friendly solder.

[0027] The content of each component is shown in Table 1.

Embodiment 3

[0029] A preparation method of a Sn-Cu-based environment-friendly solder that adds Zr, the steps of the preparation method are as follows:

[0030] a): Tin with a purity of 99.95%, copper with a purity of 99.95%, and zinc with a purity of 99.95% are heated to 1400°C in a vacuum melting furnace under the protection of argon to melt, while stirring, and then cooled to room temperature with the furnace , to obtain tin-copper-zinc alloy;

[0031] b): Heating the tin-copper-zinc alloy obtained in step a) to 650°C in an argon-protected vacuum furnace, then zirconium with a purity of 99.95%, keeping it for 5 hours and then cooling to room temperature with the furnace to obtain Zr-added Sn - Cu-based environmentally friendly solder.

[0032] The content of each component is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com