Electromagnetic valve body machining equipment

A processing equipment, solenoid valve technology, applied in metal processing equipment, precision positioning equipment, metal processing mechanical parts and other directions, can solve the problems of many operators, high processing cost, low efficiency, etc., achieve a strong degree of automation, reduce processing costs , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

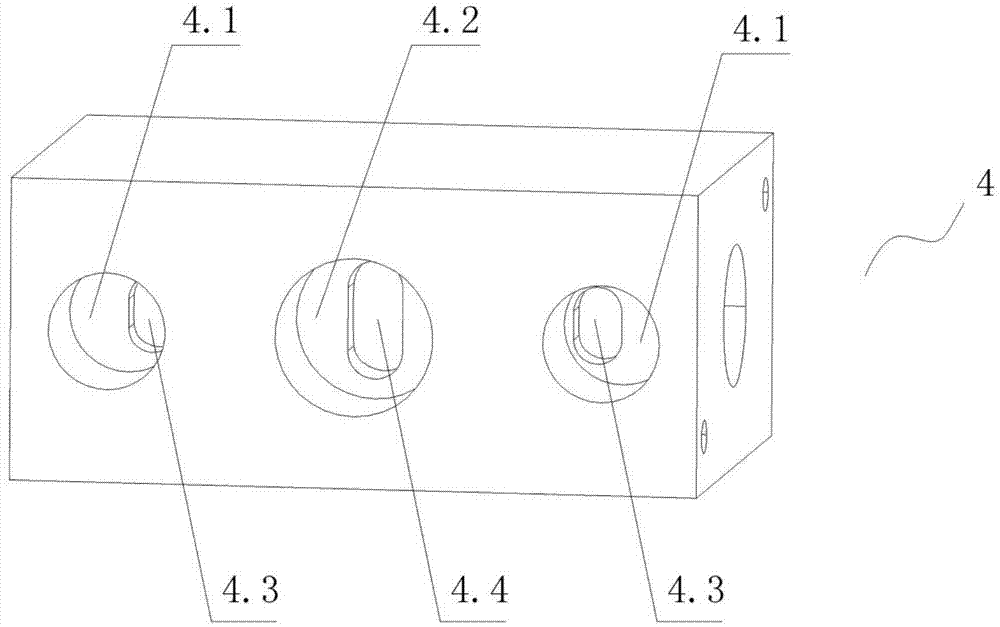

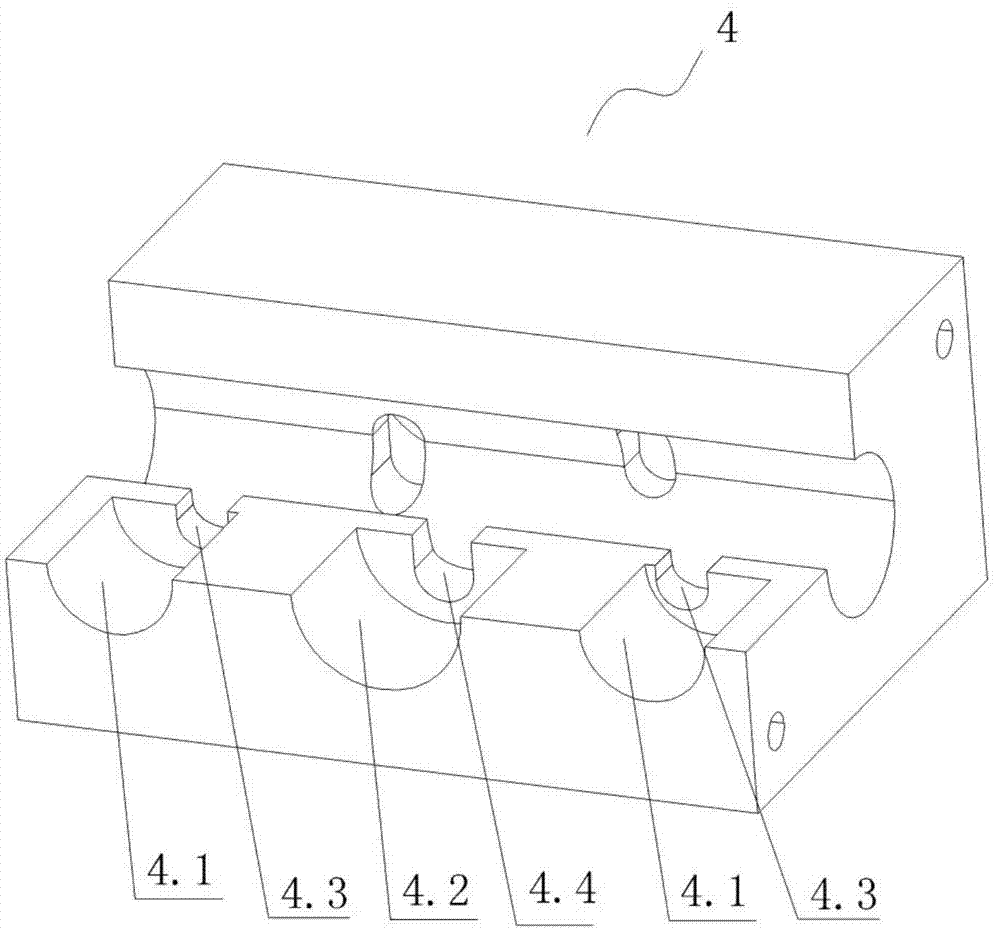

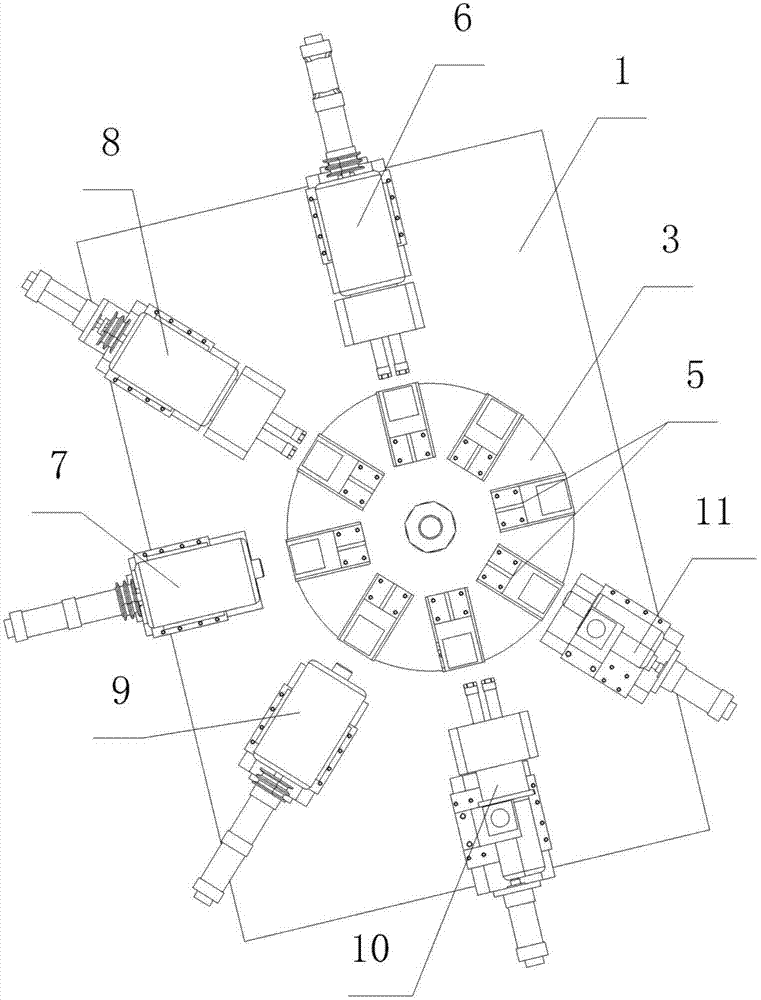

[0019] The electromagnetic valve valve body processing equipment of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] refer to Figure 1 to Figure 5 , The solenoid valve body processing equipment of the present invention includes a base 1, an intermittent divider 2 installed on the base 1, and an indexing turntable 3 installed at the output end of the intermittent divider to realize indexing and intermittent rotation. In this embodiment, the base 1 is a square bottom plate, and the intermittent divider 2 is installed vertically at the center of the square bottom plate, and the indexing turntable 3 is installed horizontally at the output end of the top of the intermittent divider 2 superior. Wherein the intermittent divider 2 can convert a continuous action into an intermittent motion, that is, an intermittent indexing rotary motion, which is a prior art, so it will not be described in detail here, and after the index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com