Drive control method for range-extended electric vehicle

A technology for electric vehicles and range extension, which is applied to electric vehicles, engine-driven traction, motor vehicles, etc., and can solve the problems of power impact and vehicle performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

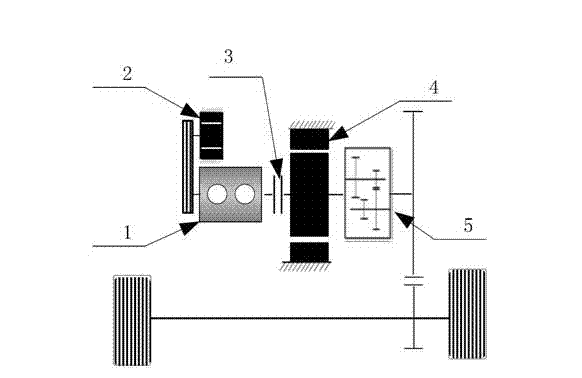

[0088] like Figure 8 As shown, the power system of an extended-range electric vehicle includes an internal combustion engine, a first electric motor, a second electric motor, a dual-clutch transmission and a planetary gear mechanism. The crankshaft of the internal combustion engine (1) is connected to the housing (2) of the dual clutch transmission. The first clutch (3) of the dual-clutch transmission is connected to the planetary gear mechanism through a shaft (14), and the second clutch (4) is connected to the first motor rotor (17). The rotor (11) of the second electric motor is connected with the planet carrier of the planetary gear mechanism, and outputs power through the ring gear. By controlling the engagement or disengagement of the first clutch (3) and the second clutch (4) of the dual-clutch transmission, the switching of the series and parallel operation modes of the assembly can be realized. like figure 1 Among them, the internal combustion engine is used to m...

Embodiment 2

[0158] like Figure 9 As shown, the power system of an extended-range electric vehicle includes an internal combustion engine, a first electric motor, a second electric motor, a dual-clutch transmission and a planetary gear mechanism. The crankshaft of the internal combustion engine (1) is connected to the housing (2) of the dual clutch transmission. The first clutch (3) of the dual-clutch transmission is connected to the planetary gear mechanism through a shaft (14), and the second clutch (4) is connected to the first motor rotor (17). The second motor rotor (11) is connected with the ring gear (5) of the planetary gear mechanism, and outputs power through the planetary carrier (6). By controlling the engagement or disengagement of the first clutch (3) and the second clutch (4) of the dual-clutch transmission, the switching of the series and parallel operation modes of the assembly can be realized. Among them, the internal combustion engine is used to meet the driving power...

Embodiment 3

[0224] like Figure 10 As shown, the power system of an extended-range electric vehicle includes an internal combustion engine, a first electric motor, a second electric motor, a dual-clutch transmission and a planetary gear mechanism. The crankshaft of the internal combustion engine (1) is connected to the housing (2) of the dual clutch transmission. The first clutch (3) of the dual-clutch transmission is connected to the planetary gear mechanism through a shaft (14), and the second clutch (4) is connected to the first motor rotor (17). The rotor of the second electric motor is connected with the sun gear of the planetary gear mechanism, and outputs power through the planet carrier. By controlling the engagement or disengagement of the first clutch (3) and the second clutch (4) of the dual-clutch transmission, the switching of the series and parallel operation modes of the assembly can be realized. Among them, the internal combustion engine is used to meet the driving power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com