Industrial bromine refining method

A refining method and industrial technology, applied in the direction of bromine/hydrogen bromide, etc., can solve the problems of unsatisfactory refining effect, affecting absorption effect, complicated production process, etc., and achieve the effect of small investment, simple operation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

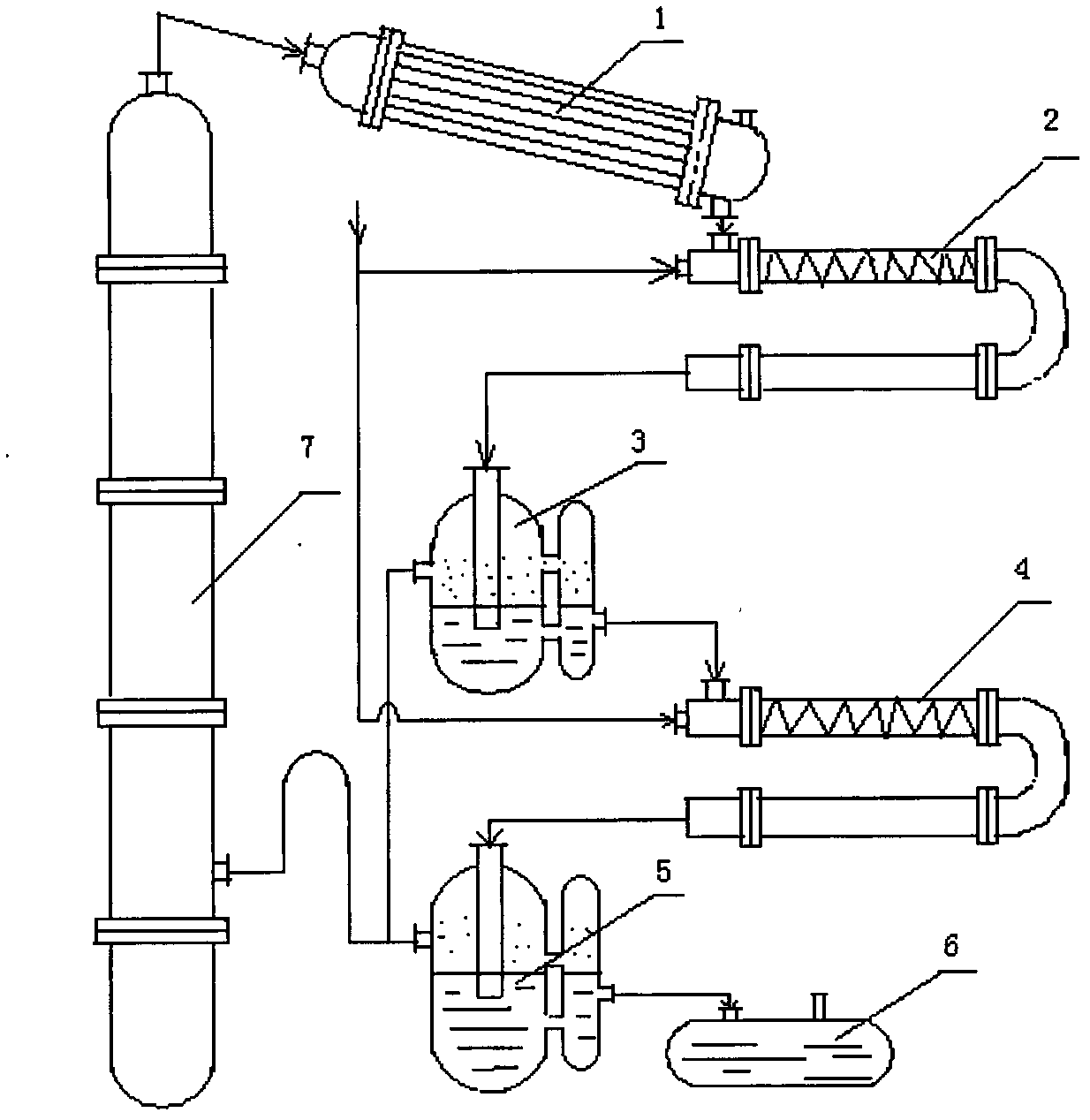

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0022] A refining method for industrial bromine is to condense distilled bromine vapor into liquid bromine through a crude bromine condenser, then adopt two-stage mixed absorption and two-stage separation steps to absorb free chlorine in the liquid bromine, and then make the crude bromine Bromine is refined by the method. The concrete steps of this method are:

[0023] (1) After the bromine vapor discharged from the distillation tower is condensed into crude liquid bromine by the crude bromine condenser, it enters the horizontally installed primary static state with the normal temperature raw material liquid whose volume flow rate is 70% of the crude liquid bromine with the material flow direction perpendicular to each other. Mixer, fully mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com