Additive capable of improving durability of steam-cured concrete, and concrete coarse aggregate treated thereby

A technology of concrete and additives, applied in the field of building materials, can solve the problems of insufficient durability, insufficient strength development, negative effects of volume stability of concrete materials, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

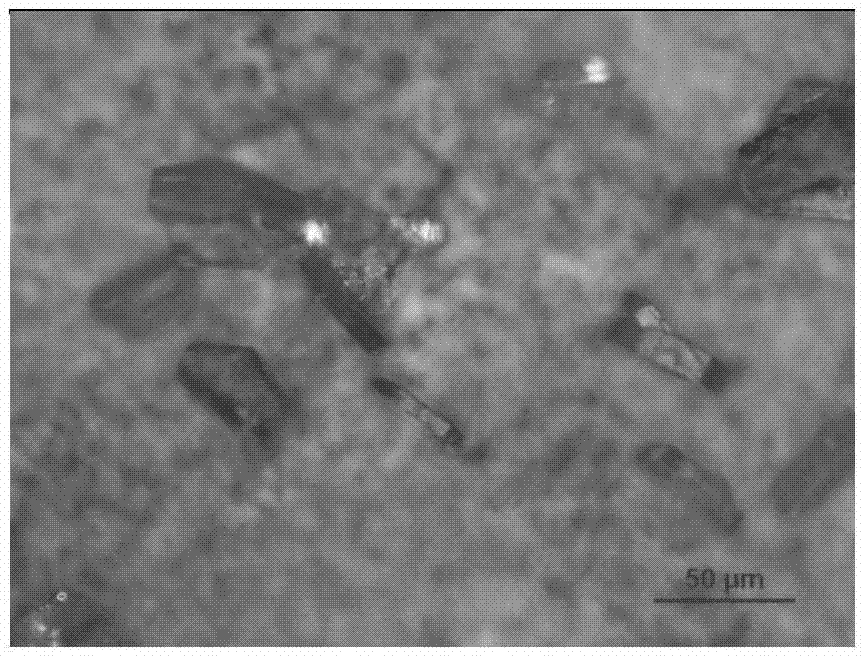

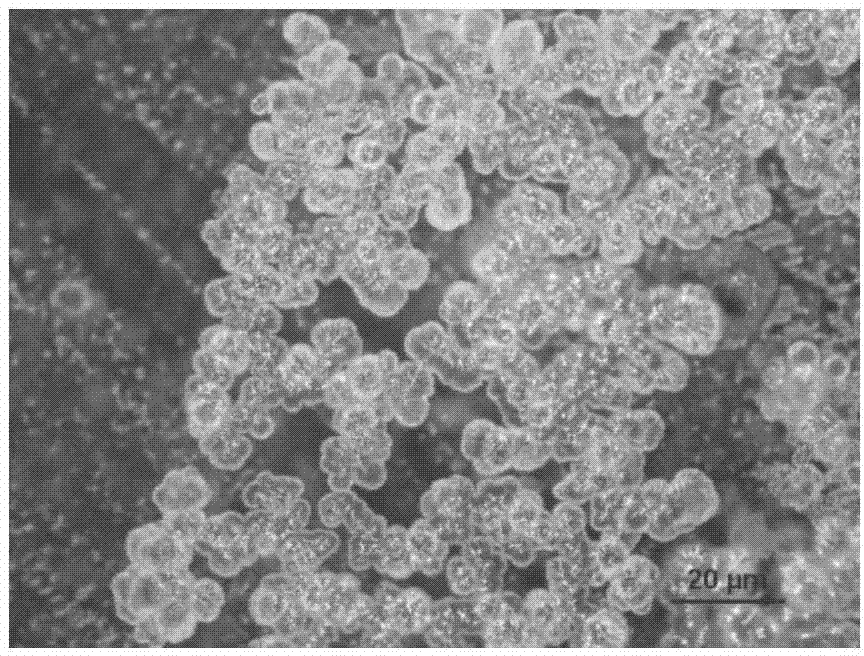

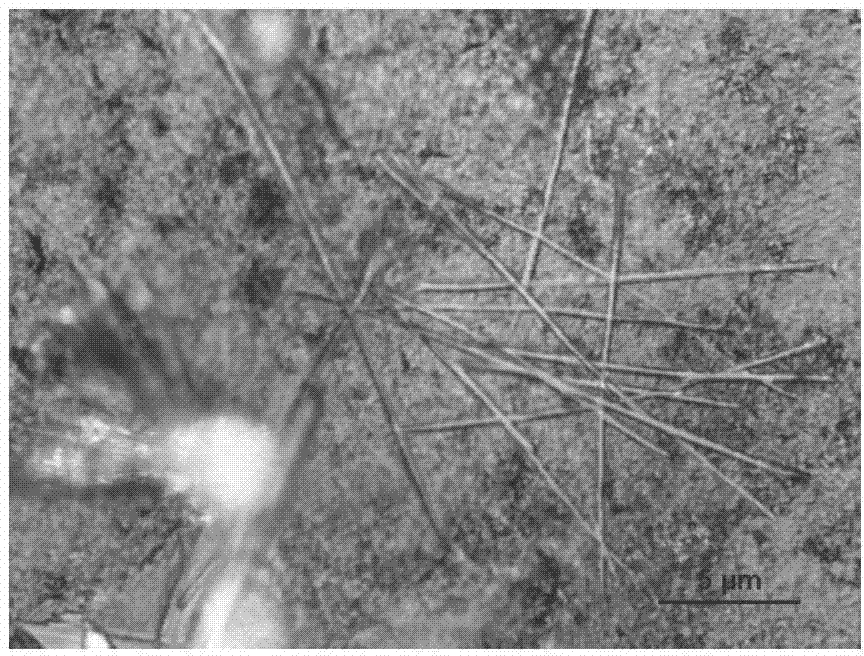

Image

Examples

Embodiment 1

[0026] Concrete mix ratio: cement 457kg / m 3 , sand 619kg / m 3 , coarse aggregate 1140kg / m 3 , water 160kg / m 3 . The additive is composed of 20wt% polycarboxylic acid (average molecular weight: 20,000) and 80wt% tetrasodium aminotrimethylidene phosphate (organic phosphate). Weigh the additive accounting for 0.25% of the mass of concrete coarse aggregate and make it into a concentration For a 2wt% solution, add an appropriate amount of NaOH to adjust the pH value to 7.2. Soak the coarse aggregate in the above solution for 24 hours and take it out to dry. When mixing concrete, first mix and stir cement, sand and water for 120 seconds, then add the above-mentioned treated coarse aggregate, stir for 20 seconds, and then discharge to shape. In contrast, the coarse aggregate used in the benchmark concrete was prepared and shaped using the same mixing process without any treatment. The above two concrete specimens were demolded after being cured in a steam curing box at 60°C for 8...

Embodiment 2

[0028] Concrete mix ratio: cement 457kg / m 3 , sand 619kg / m 3 , coarse aggregate 1140kg / m 3 , water 160kg / m 3 . The additive is composed of 50wt% sodium lignosulfonate and 50wt% polyol phosphate (organic phosphate). Weigh the additive accounting for 1% of the mass of concrete coarse aggregate, make it into a solution with a concentration of 4wt%, and add an appropriate amount of NaOH Adjust the pH to a value of 7.2. Soak the coarse aggregate in the above solution for 24 hours and take it out to dry. When mixing concrete, first mix and stir cement, sand and water for 120 seconds, then add the above-mentioned treated coarse aggregate, stir for 20 seconds, and then discharge to shape. In contrast, the coarse aggregate used in the benchmark concrete was prepared and shaped using the same mixing process without any treatment. The above two concrete specimens were demolded after being cured in a steam curing box at 60°C for 8 hours, and then transferred to the standard curing ro...

Embodiment 3

[0030] Concrete mix ratio: cement 457kg / m 3 , sand 619kg / m 3 , coarse aggregate 1140kg / m 3 , water 160kg / m 3 . The additive is composed of 40wt% polycarboxylic acid (average molecular weight: 20,000) and 60wt% polyacrylamide (average molecular weight: 6 million). Weigh the additive that accounts for 1.50% of the mass of concrete coarse aggregate, and make it into a concentration of 5wt%. solution, adding an appropriate amount of NaOH to adjust the pH value to 7.2. Soak the coarse aggregate in the above solution for 24 hours and take it out to dry. When mixing concrete, first mix and stir cement, sand and water for 120 seconds, then add the above-mentioned treated coarse aggregate, stir for 20 seconds, and then discharge to shape. In contrast, the coarse aggregate used in the benchmark concrete was prepared and shaped using the same mixing process without any treatment. The above two concrete specimens were demolded after being cured in a steam curing box at 60°C for 8 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com