A gas purification system that can realize slag heat utilization

A gas purification system and gas purification technology, applied in the direction of gas dust removal, gas purification of condensed non-gaseous materials, chemical industry, etc., can solve the problem of inconvenient use of shale oil in the future, and achieve the effect of increasing the outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

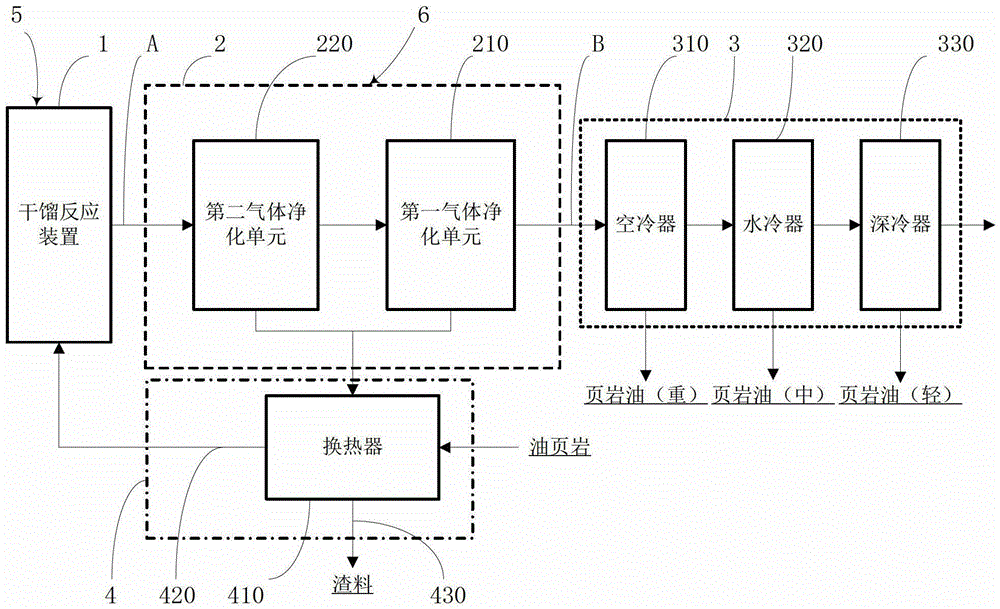

[0052] The oil shale dry distillation system includes a dry distillation reaction unit 1 and a condensation recovery system 3. The condensation recovery system 3 mainly includes a three-stage condensation system composed of an air cooler 310, a water cooler 320, and a deep cooler 330 arranged in sequence according to the condensation recovery route. In the recovery system, the bottom of each cooler is equipped with a shale oil discharge pipeline; the dry distillation product release end A of the dry distillation reaction device 1 and the dry distillation product receiving end B of the condensation recovery system 3 pass through the gas dust removal system 2 Connected, the gas dedusting system 2 includes a first gas purification unit 210 and a second gas purification unit 220 arranged at the front end of the first gas purification unit 210 according to the dust removal and purification direction. The second gas purification unit 220 adopts a gravity dust collector, and the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com