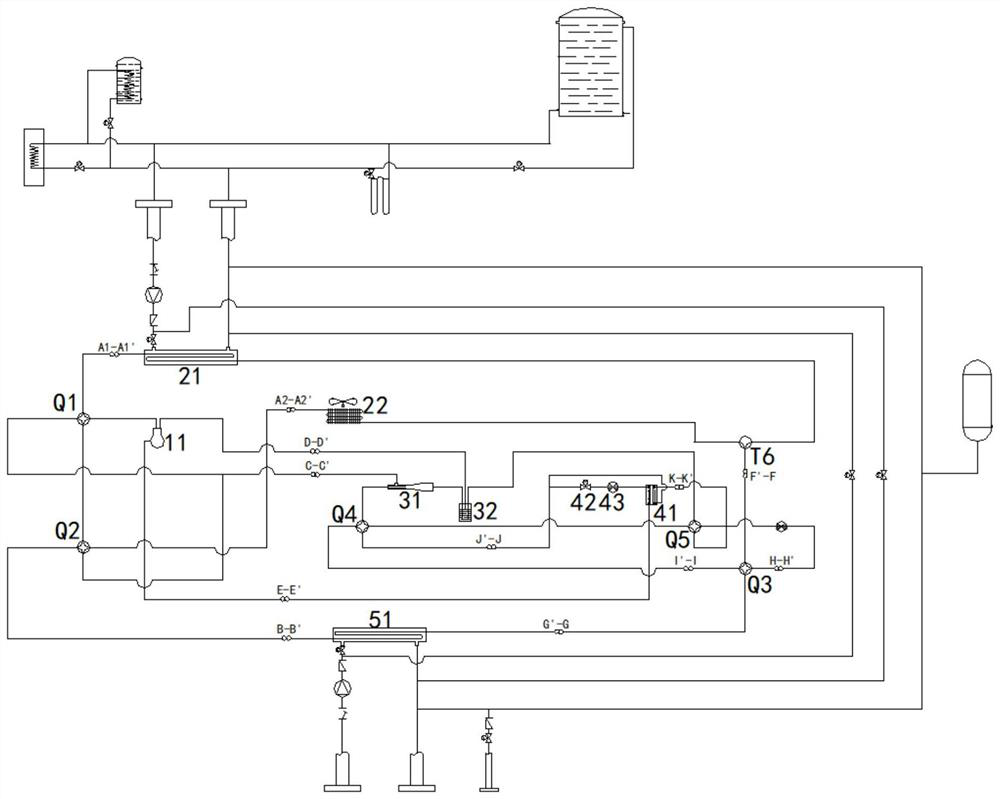

Integrated water-cooling air-cooled heat pump module unit and multi-source system

An air-cooled heat pump and water cooling technology, applied in refrigerators, refrigeration components, compressors, etc., can solve the problems of large volume of water-cooled chillers, unusable installation sites, lack of heating function, etc., and achieve diversification of cold and heat sources. , The effect of cooling and heating efficiency and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

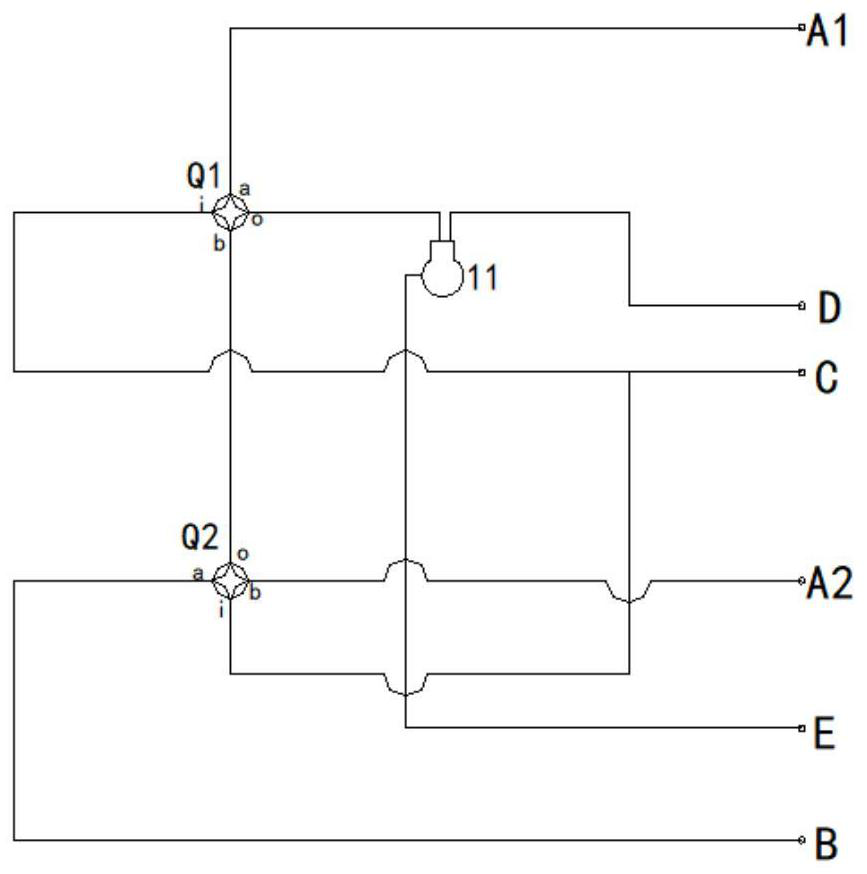

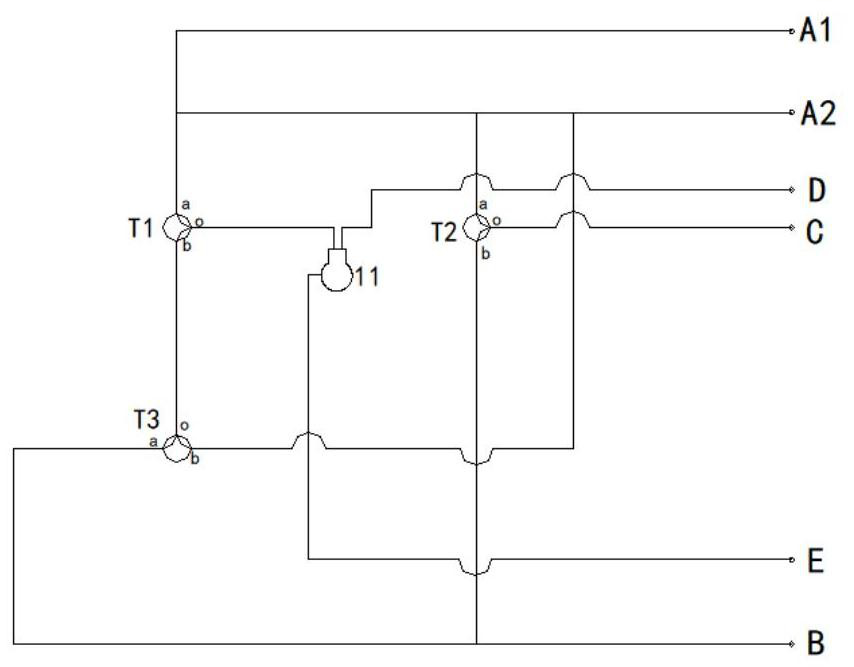

[0109] refer to Figure 20 , Water-cooled injection cooling mode:

[0110] Refrigerant circulation system: the first four-way valve Q1oa and bi are connected; the second four-way valve Q2ia and bo are connected; the third four-way valve Q3ib and ao are connected; the fourth four-way valve Q4ob and ai are connected Connected; the Q5ia and bo ports of the fifth four-way valve are connected; the sixth three-way valve T6bo is connected; the enthalpy increasing solenoid valve 42 is closed.

[0111] Refrigerant circulation path:

[0112] The refrigerant flows sequentially through the steam injection port of the compressor 11, the first valve port o and the third valve port a of the first four-way valve Q1, the water source heat exchanger 21, the third valve port b and the third valve port of the sixth three-way valve T6 One valve port o, the first valve port o and the third valve port a of the third four-way valve Q3 of the rectification module, the second valve port i and the thi...

Embodiment 2

[0123] refer to Figure 21 , air-cooled injection cooling mode:

[0124] Refrigerant circulation system: the first four-way valve Q1ob and ai terminals are connected; the second four-way valve Q2ob and ai are connected; the third four-way valve Q3oa and bi are connected; the fourth four-way valve Q4ia and bo are connected Connected; the Q5ai and ob ports of the fifth four-way valve are connected; the sixth three-way valve T6bo is connected; the enthalpy increasing solenoid valve 42 is closed.

[0125] In the high-pressure refrigerant circuit of the refrigerant cycle, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the fourth valve port b of the first four-way valve Q1, the first valve port o and the first valve port b of the second four-way valve Q2, and The fourth valve port b, the air source heat exchanger 22, the third valve port a and the first valve port o of the sixth three-way valve T6, the first valve port o and ...

Embodiment 3

[0134] refer to Figure 22 , ground (water) source heat pump cooling mode:

[0135] Refrigerant circulation system: the first four-way valve Q1ao and bi are connected; the second four-way valve Q2oa and bi are connected; the third four-way valve Q3ib and ao are connected; the fourth four-way valve Q4ib and ao are connected Connected; the Q5ib and ao ports of the fifth four-way valve are connected; the sixth three-way valve T6bo is connected; the enthalpy increasing solenoid valve 42 is closed.

[0136] The refrigerant circulation path is:

[0137] In the refrigerant circuit, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the third valve port a of the first four-way valve Q1, the water source heat exchanger 21, and the fourth valve of the sixth three-way valve T6 Port b and the first valve port o, the first valve port o and the third valve port a of the third four-way valve Q3, the second valve port i and the fourth val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com