Spinneret plate for spinning

A spinneret and spinning technology, applied in the field of spinning, can solve the problems of difficult processing of pure special-shaped spinneret holes, poor fiber spinnability, and poor fabric gloss, so as to improve the spinnability, reduce the difficulty of processing, and improve the fabric quality. full color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The spinneret for spinning of the present invention will be further described in detail through specific examples below.

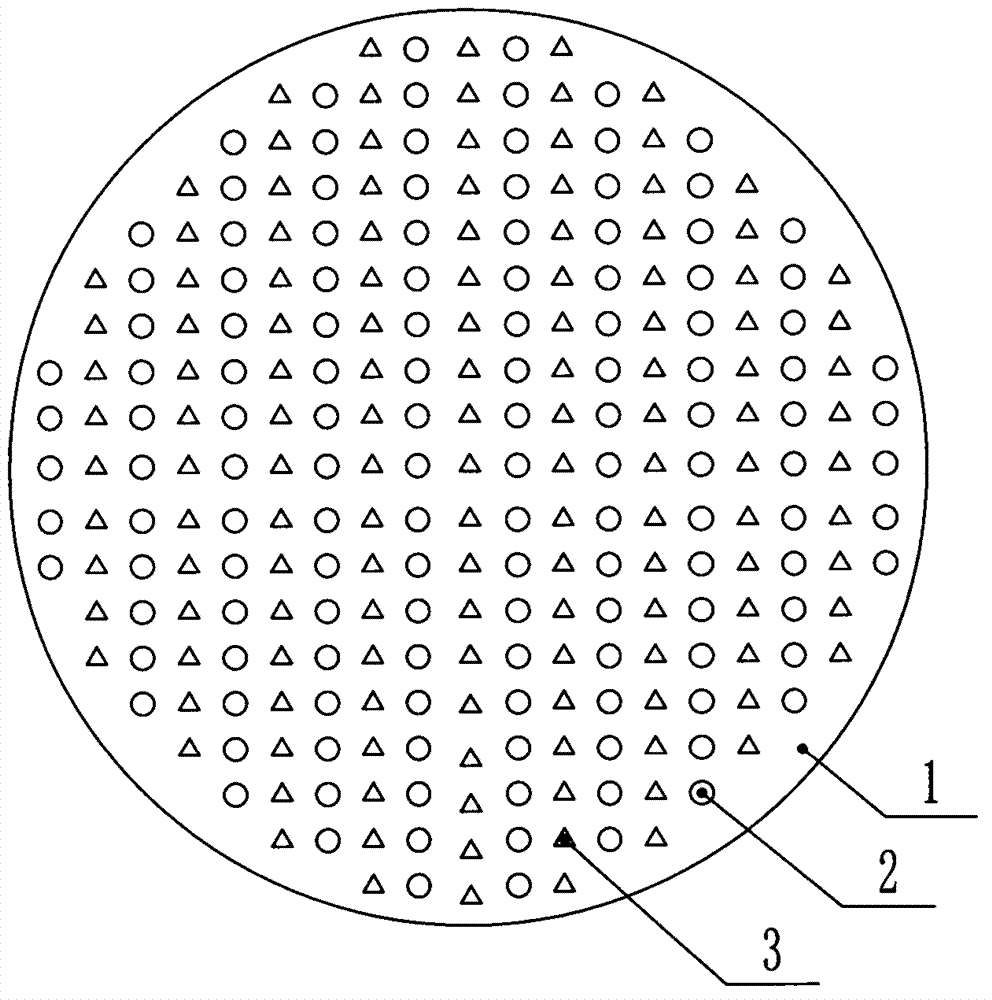

[0009] Such as figure 1 As shown, the spinneret used for spinning includes a spinneret body 1, and a spinneret hole is arranged in the spinneret body 1, and the spinneret hole includes a circular spinneret hole 2 and a special-shaped spinneret hole 3, The circular spinneret holes 2 are vertically arranged in several rows, the special-shaped spinneret holes 3 are vertically arranged in several rows, and the circular spinneret holes 2 and the special-shaped spinneret holes 3 are arranged at intervals in columns.

[0010] The above-mentioned spinneret for spinning has circular spinneret holes 2 and special-shaped spinneret holes 3 arranged at intervals in the spinneret body 1, and circular fibers and special-shaped fibers can be ejected simultaneously during production, thereby It can not only improve the spinnability of the finished fiber, but also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com