Core drilling drill with barrier crushing and chip-discharge functions

A core drill bit and drill bit technology, which is applied in the aerospace field, can solve problems such as cutting tool wear, drill pipe bending deformation, and drill sticking, and achieve the effects of solving frictional heating, reducing frictional heating, and reducing frictional heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

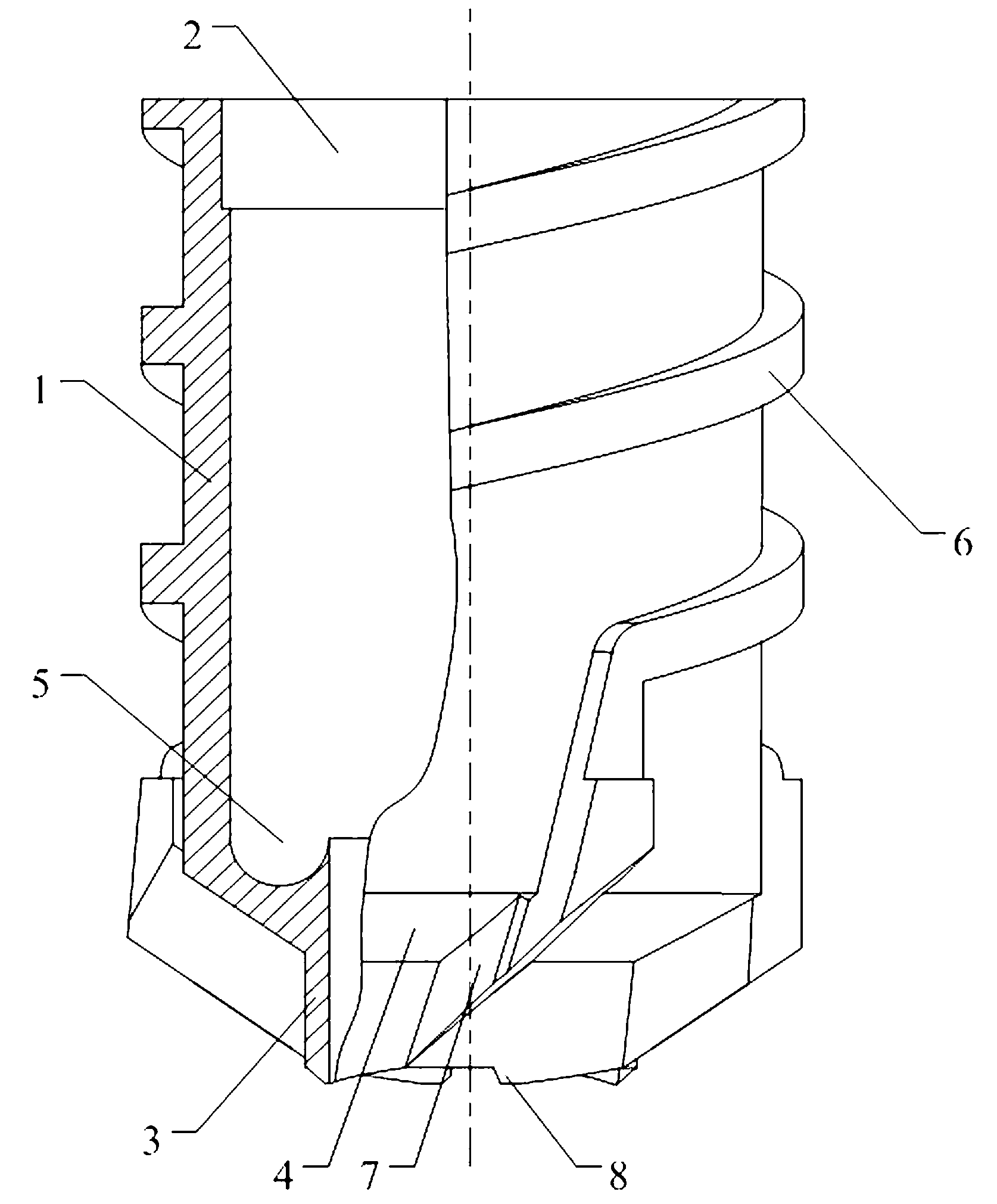

[0016] Examples of the present invention figure 1 As shown, the drilling core bit with the function of breaking barrier and chip removal is provided with a hollow cylindrical drill base 1, the upper end of which is provided with a drill pipe connecting portion 2 for connecting with the drill pipe, and the lower end is radially retracted to form a The isolating cutting ring 3, the convex table surface formed by the retraction of the drill base 1 is a slope 4, and a coring mechanism placement space 5 is formed between the drill base 1 and the isolating cutting ring 3, which is used to place a tubular coring mechanism; the drill base 1 The outer surface is connected with an outer spiral 6, and the outer surface of the isolation cutting ring 3 and the inclined surface 4 are connected with cutting tools 7 uniformly distributed in the circumferential direction. flush; the lower end of the isolation cutting ring 3 is provided with circumferentially distributed annular cutting teeth 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com