Novel sucker rod centralizing paraffin scraper

A wax scraper and sucker rod technology, used in drill pipes, cleaning appliances, drilling equipment, etc., can solve the problems of reducing the overflow section, increasing the oil flow resistance, unable to remove wax, etc., to reduce the resistance and reduce the movement resistance. , The effect of preventing the breakage of the sucker rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

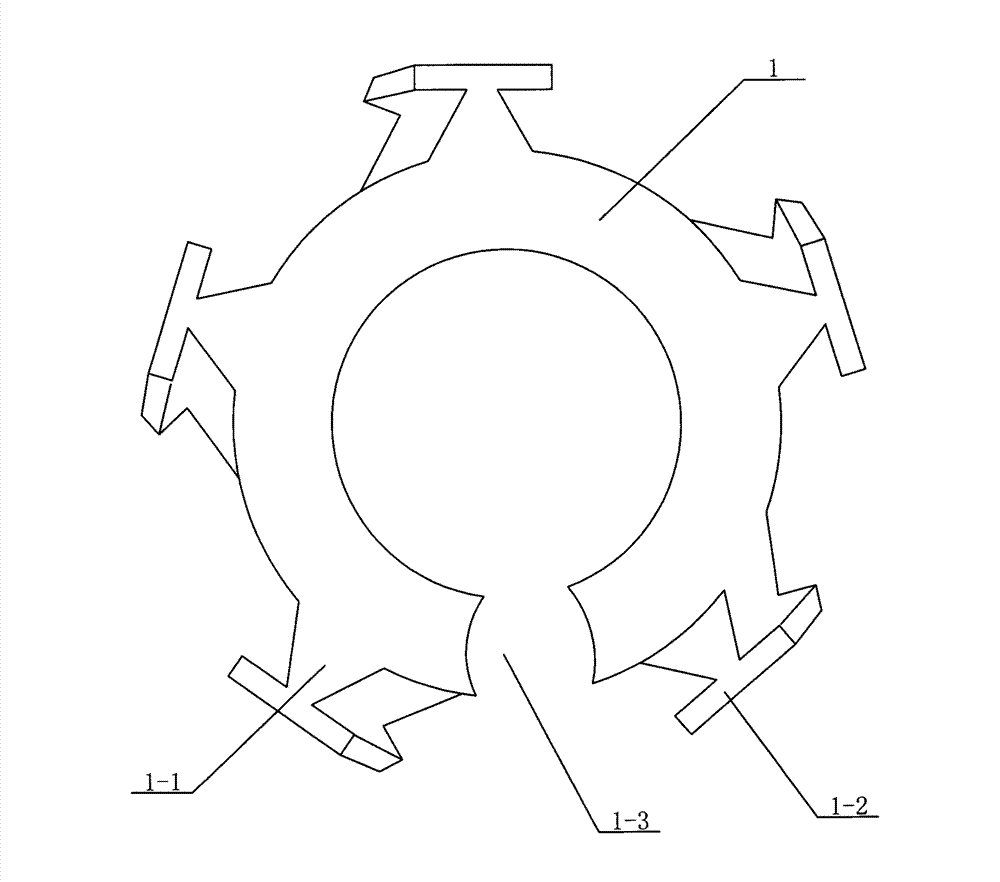

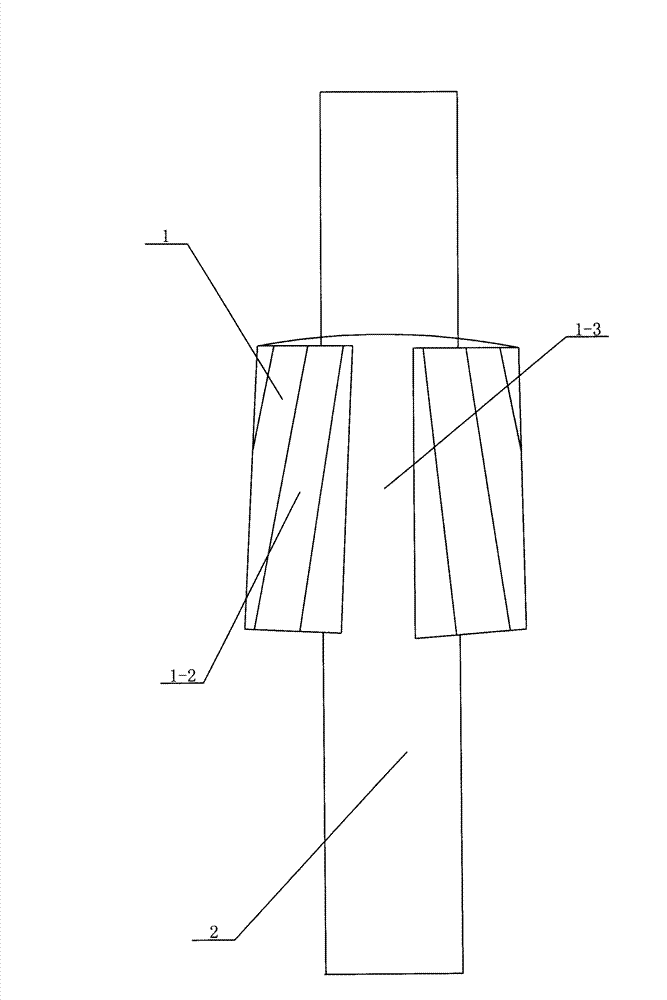

[0012] see figure 1 , figure 2 , the specific embodiment adopts the following technical scheme: it includes a centralizing wax scraper body 1, and several tower-shaped spiral teeth 1-1 are arranged on the centralizing wax scraper body 1, and the top of the tower-shaped spiral tooth 1-1 is provided with a tower Shaped helical tooth 1-1 vertical helical baffle 1-2.

[0013] The centralizing wax scraper body 1 is provided with a longitudinal opening 1-3.

[0014] The opening size of the longitudinal openings 1-3 is 1 / 3 of the diameter of the sucker rod 2 .

[0015] In this specific embodiment, the body 1 of the righting wax scraper becomes soft after being boiled and heated, and is stuck on the sucker rod 2 by the longitudinal opening. 1 / 3 of the diameter of the sucker rod 2 can ensure that the wax scraper body 1 will not slip off from the sucker rod 2 during work, and a spiral baffle 1- 2. While the wax scraping effect of the oil pipe can be ensured, the flow area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com