Drilling and cutting integrated outburst preventing and permeability improving system for mines

A drilling and cutting and outburst prevention technology, which is applied in the direction of liquid/gas jet drilling, mining fluid, mining equipment, etc., can solve the problems of increasing construction procedures, achieve the effects of reducing labor costs, reasonable design, and improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

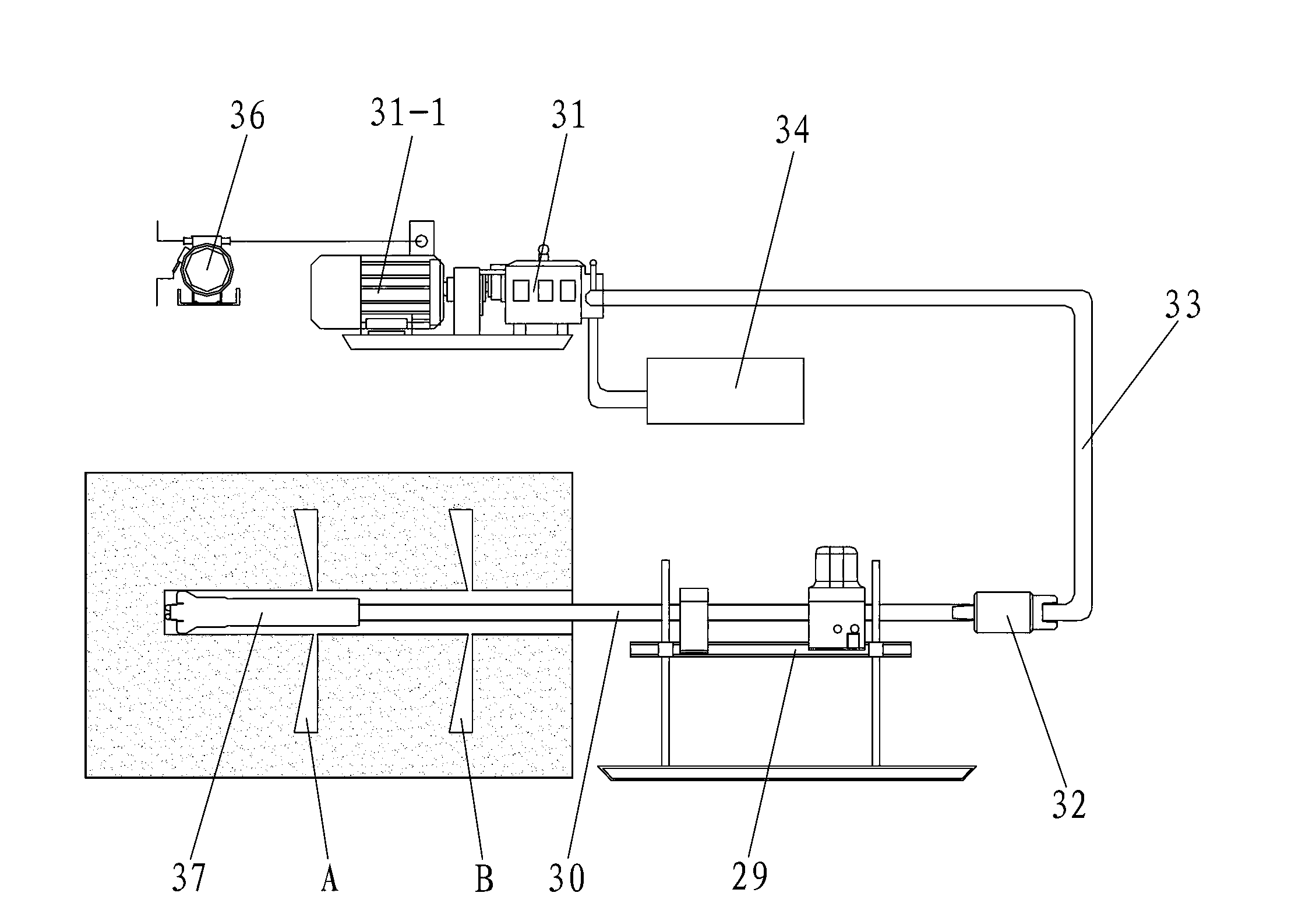

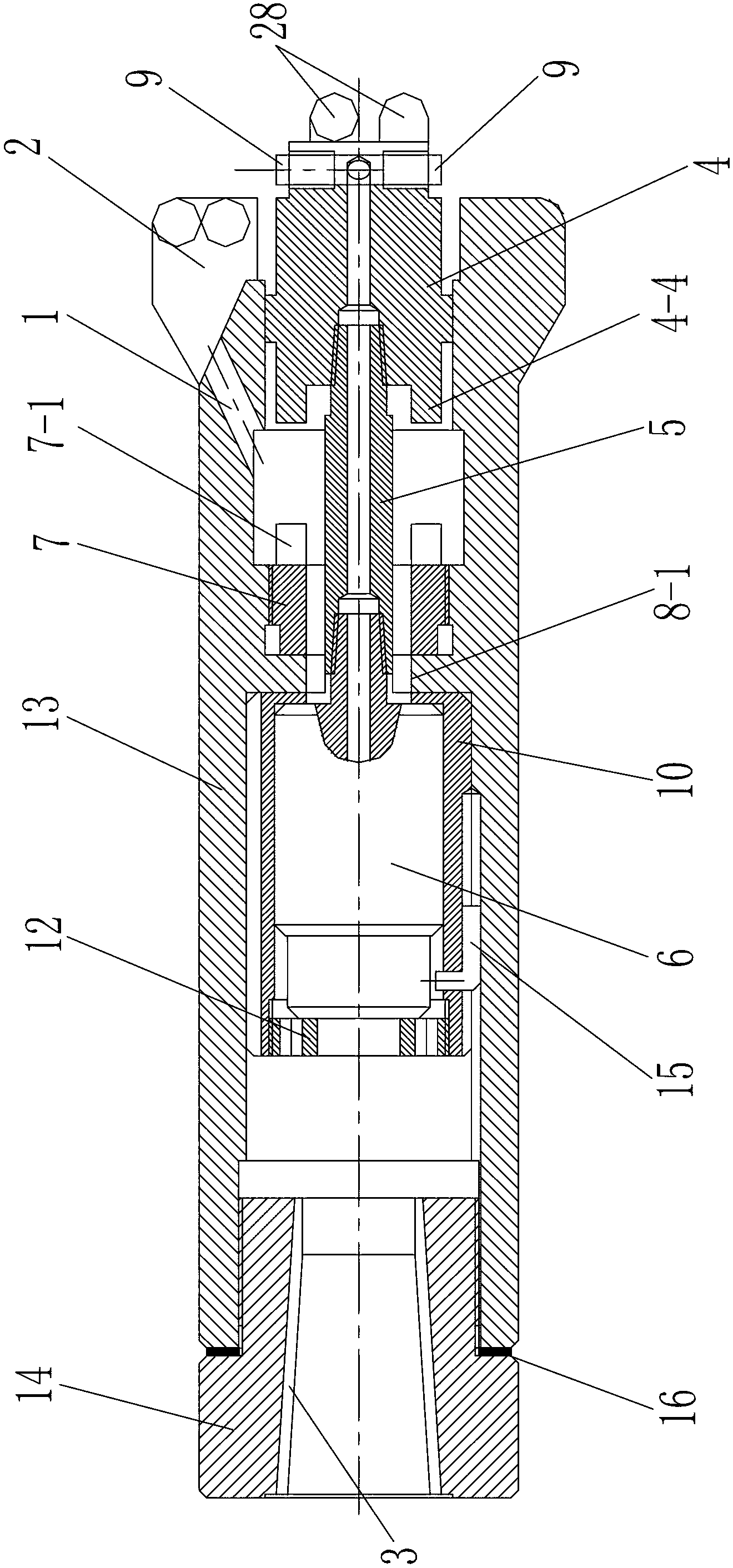

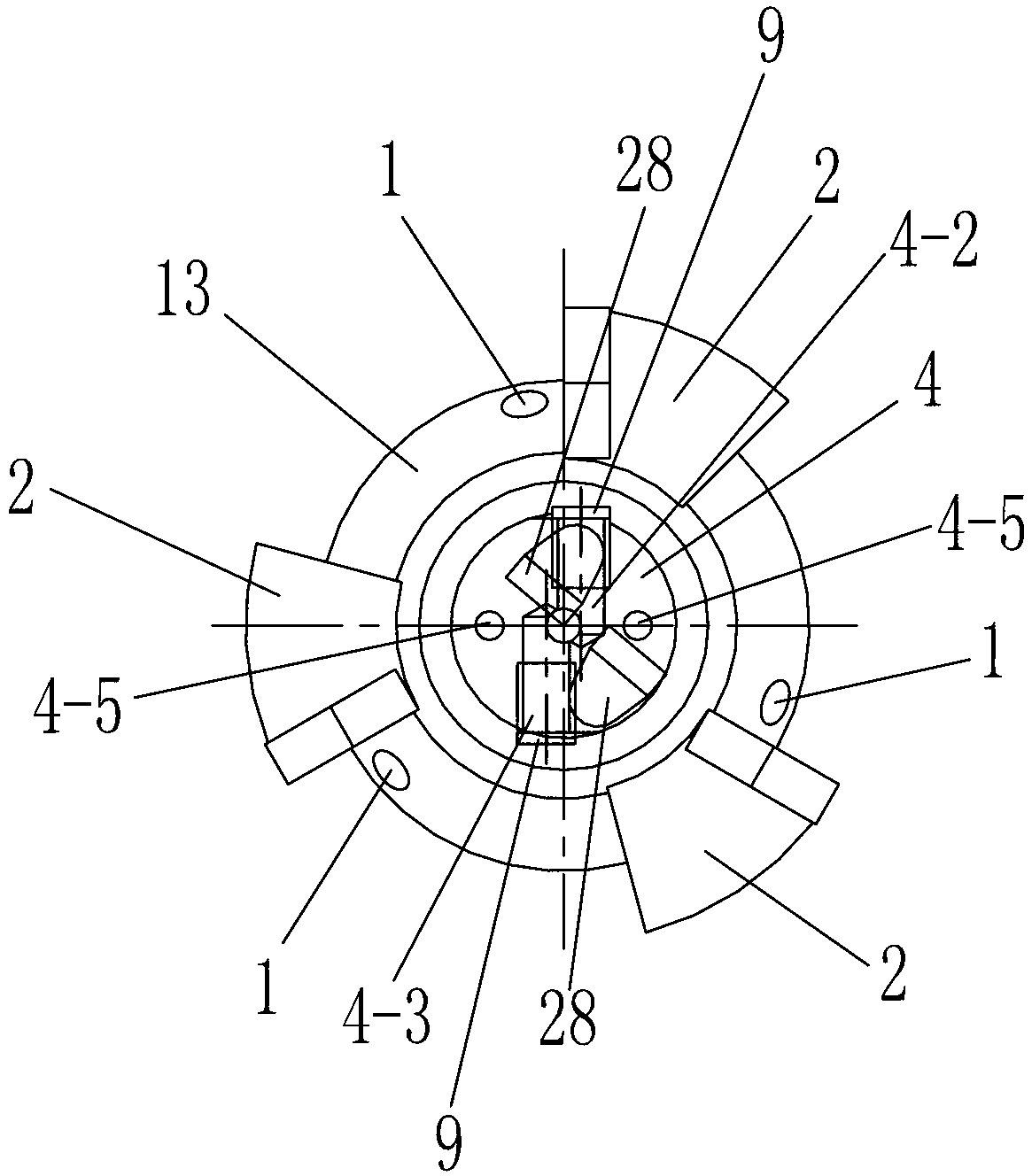

[0077] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a drill 29, a drill rod 30 clamped on the drill 29, and a drill bit connected to one end of the drill rod 30, and also includes a water tank 34 and a water tank 34 for pressurizing the water in the water tank 34. The high-pressure pump station 31 for transportation. The drill bit is a drilling and cutting integrated drill bit 37. The other end of the drill rod 30 is connected with a high-pressure hose 33 for conveying water to the drill rod 30 through a first rotary joint 32. The high-pressure pump The inlet of the station 31 is connected with the outlet of the water tank 34, and the outlet of the high-pressure pump station 31 is connected with a high-pressure hose 33; the drilling and cutting integrated drill 37 includes a drill housing and a hydraulic cutting assembly arranged in the drill housing. The integrated drill bit 37 realizes the switching of drilling and cutting through the lat...

Embodiment 2

[0092] Combine Figure 9 ~ Figure 13 The difference between this embodiment and the first embodiment is that the high-pressure hose 33 is connected with a pressure controller 35 for controlling the pressure of the water in the high-pressure hose 33. The rear end of the second rotary joint 6 is connected with a second pipe 17, and the rear end of the second pipe 17 is connected with a sealing cover 18, and the center of the sealing cover 18 is provided with a sealing cover central hole 18 through which water flows. -1, the outer diameter of the front half of the sealing cover 18 is greater than the outer diameter of the rear half, and the front end surface of the sealing cover 18 can abut the rear end surface of the second limiting mechanism. The rear end of the sealing cover 18 is provided with a filter screen 19 covering the central hole of the sealing cover 18, and the rear end of the sealing cover 18 is connected with an end cover 20 for fixing the filter screen 19. The cen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap