Water hammer-resistant constant-pressure pressure reducing valve

A pressure reducing valve and water hammer technology, applied in the field of pressure reducing valves, can solve problems such as damage to pressure reducing valve equipment, no anti-water hammer device, complex structure, etc., and achieve the effects of avoiding strong impact, low cost, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

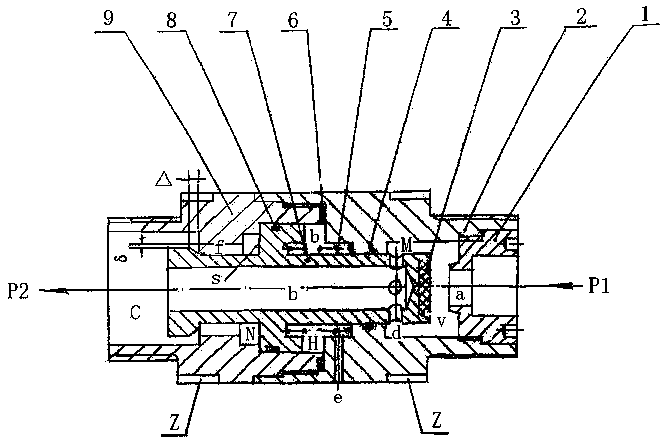

[0032] Such as figure 1 The shown anti-water hammer constant pressure reducing valve, the present invention consists of a valve seat sleeve 1, a valve body 2, a valve disc 3, a seal 4, a spring 5, a gasket 6, a valve core 7, a grid ring 8 and The valve body is composed of 9 parts.

[0033] The valve body 2 is a stepped cylinder with a stepped inner hole. The valve seat cover 1 is screwed into the water inlet at the upstream end, and a stop is provided to ensure that the inner hole a of the valve seat cover 1 is consistent with the center line of the water inlet , The downstream end of the valve seat sleeve 1 is provided with an annular edge as the valve seat of the valve port V; the cavity between the valve body 1-2 and the valve seat sleeve 1 is the intermediate cavity M; the water inlet of the valve body 1-2 is used outside The thread is connected with the water supply pipe.

[0034] The inner holes on the upstream side and the middle section of the valve body two 9 are cylinder...

Embodiment 2

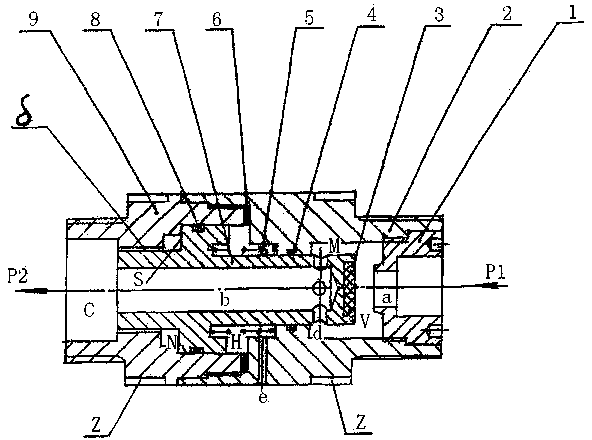

[0040] figure 2 As shown, the matching gap between the outer diameter of the sleeve on the downstream side of the valve core 7 and the inner diameter of the middle section of the valve body 9 is δ. When a shock wave is generated, this gap acts as a damping agent to prevent the valve core 7 from rapidly moving upstream.

Embodiment 3

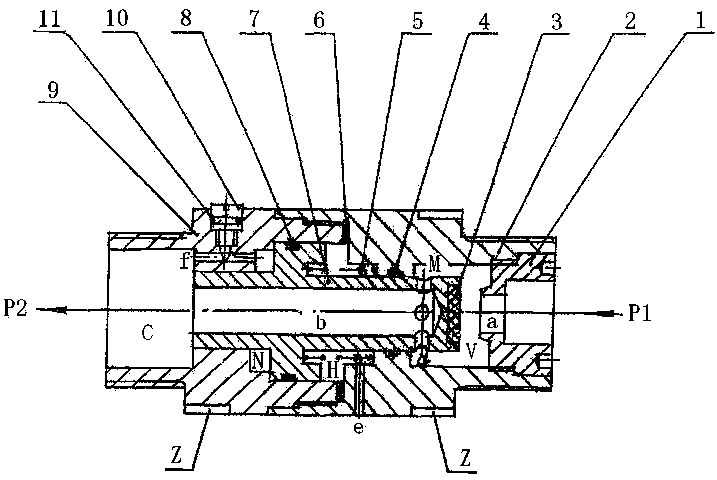

[0042] image 3 As shown, the outer diameter of the sleeve on the downstream side of the valve core 7 and the cylinder barrel in the middle section of the valve body 9 are in a sliding fit, with a small fit clearance. A small hole f is drilled on the partition wall of the cylinder. When an impact occurs, the moving speed of the valve core 7 is controlled and adjusted by the opening of the needle valve 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com