LED (Light Emitting Diode) lamp without heat radiator and production process of LED lamp

A technology of LED lights without heat sinks, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., and can solve the problems of large volume, affecting the service life of LED lights, and poor heat dissipation, etc., to achieve Reduced size, excellent lighting performance, and the effect of saving overall materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

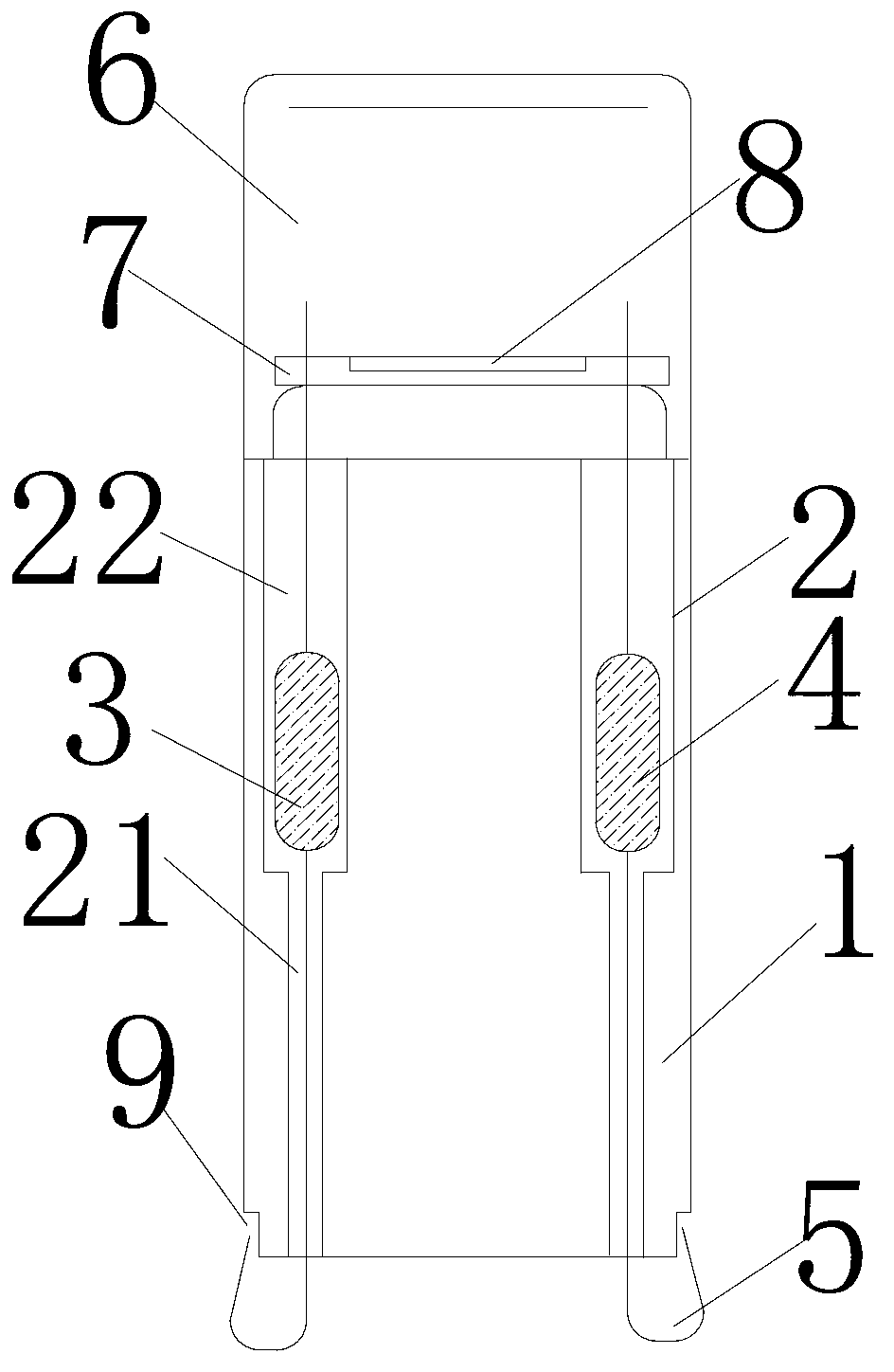

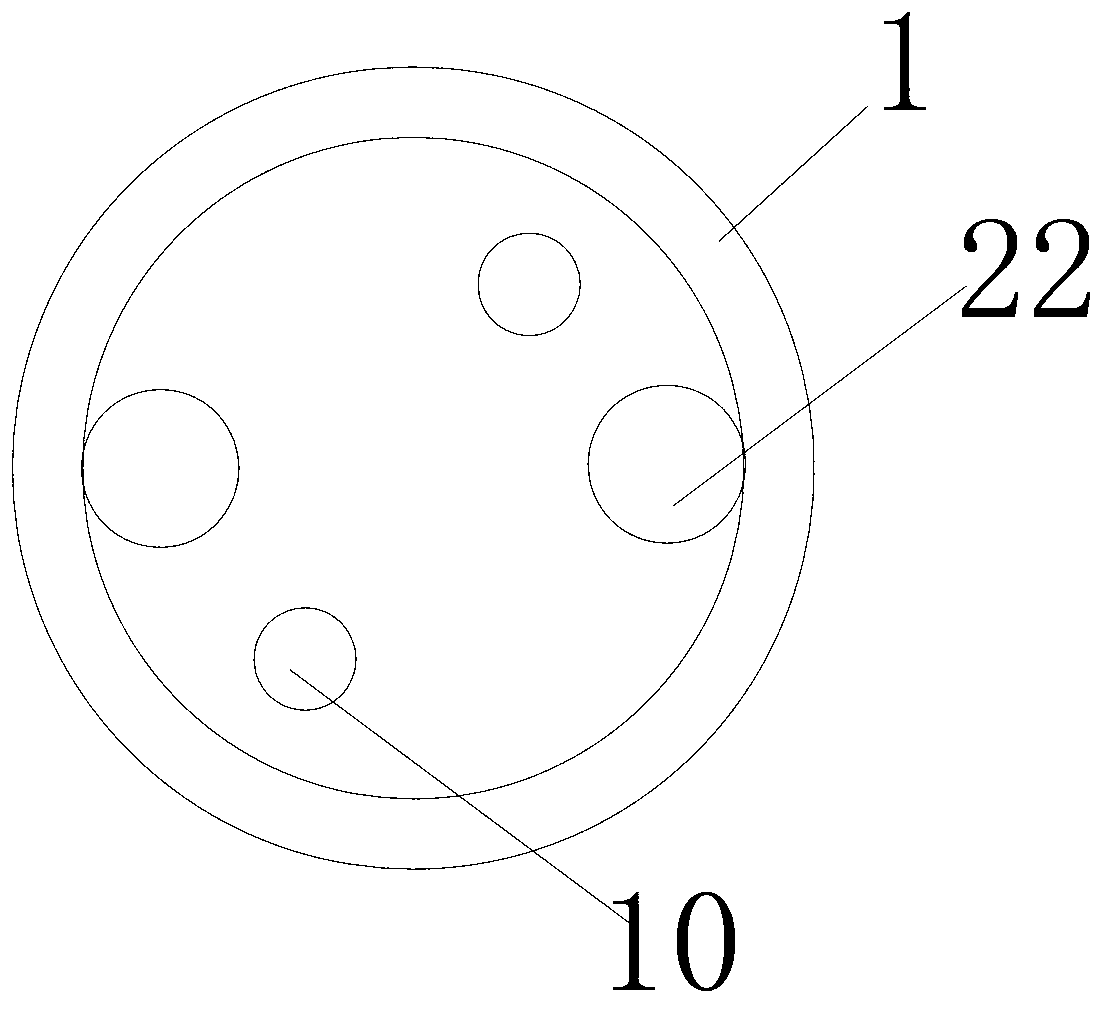

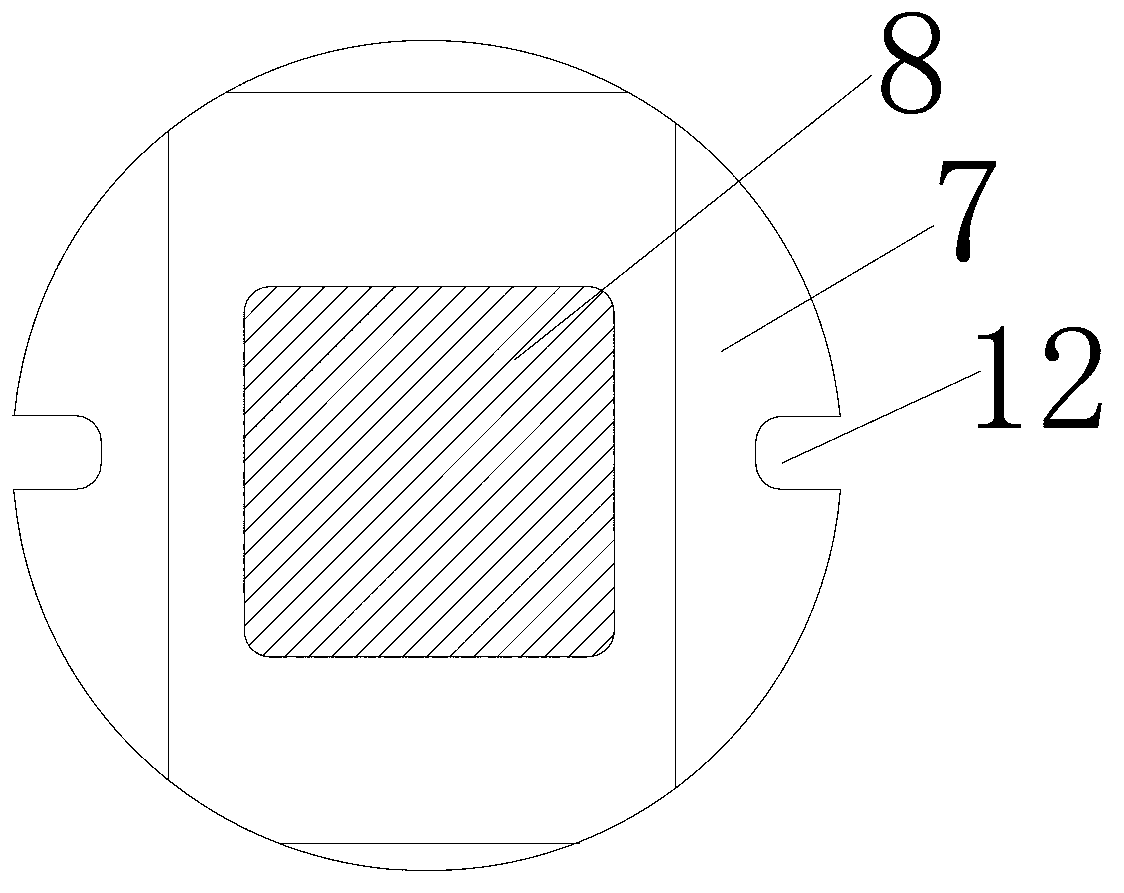

[0027] refer to figure 1 , the LED lamp without radiator of the present invention includes a ceramic shell 1, a first resistor 3, a second resistor 4, a lamp bead 8, a lamp bead plate 7 and a lampshade 6, and the ceramic shell 1 is provided with two transformers in the axial direction. diameter through hole 2, see figure 2 , the upper end surface of the ceramic shell 1 is provided with two protrusions 10, the lower end of the ceramic shell 1 is provided with two pin slots 9, the longitudinal section of the pin slot 9 is rectangular, and the two pin slots 9 They are respectively located on the outside of the two diameter-reducing through holes 2, refer to Figure 4 , the bottom of the lamp bead board 7 is provided with a pit 11 matching the protrusion 10 of the ceramic shell 1, and two grooves 12 are opened on the side of the lamp bead board 7; the first resistor 3 and the second resistor 4 are respectively Installed in two diameter-reducing through-holes 2, the lower pins o...

Embodiment 2

[0030] refer to Figure 5 , the LED lamp without radiator of the present invention includes a ceramic shell 1, a first resistor 3, a PTC assembly, a lamp bead 8, a lamp bead plate 7 and a lampshade 6, and two variable-diameter passages are opened on the axial direction of the ceramic shell 1. Hole 2, see figure 2 , the upper end surface of the ceramic shell 1 is provided with two protrusions 10, the lower end of the ceramic shell 1 is provided with two pin slots 9, the longitudinal section of the pin slot 9 is rectangular, and the two pin slots 9 They are respectively located on the outside of the two diameter-reducing through holes 2, refer to Figure 4 , the bottom of the lamp bead board 7 is provided with a pit 11 that matches the protrusion 10 of the ceramic housing 1, and two grooves 12 are opened on the side of the lamp bead board 7; the first resistor 3 and the PTC assembly are respectively installed in In the two diameter-reducing through-holes 2, the lower pin of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com