Detection device and method of liquid viscosity coefficient based on ultrasonic guided wave

A technology of viscosity coefficient and ultrasonic guided wave, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of cumbersome experimental operation and poor environmental adaptability, and achieve the effect of small size, low hardware requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

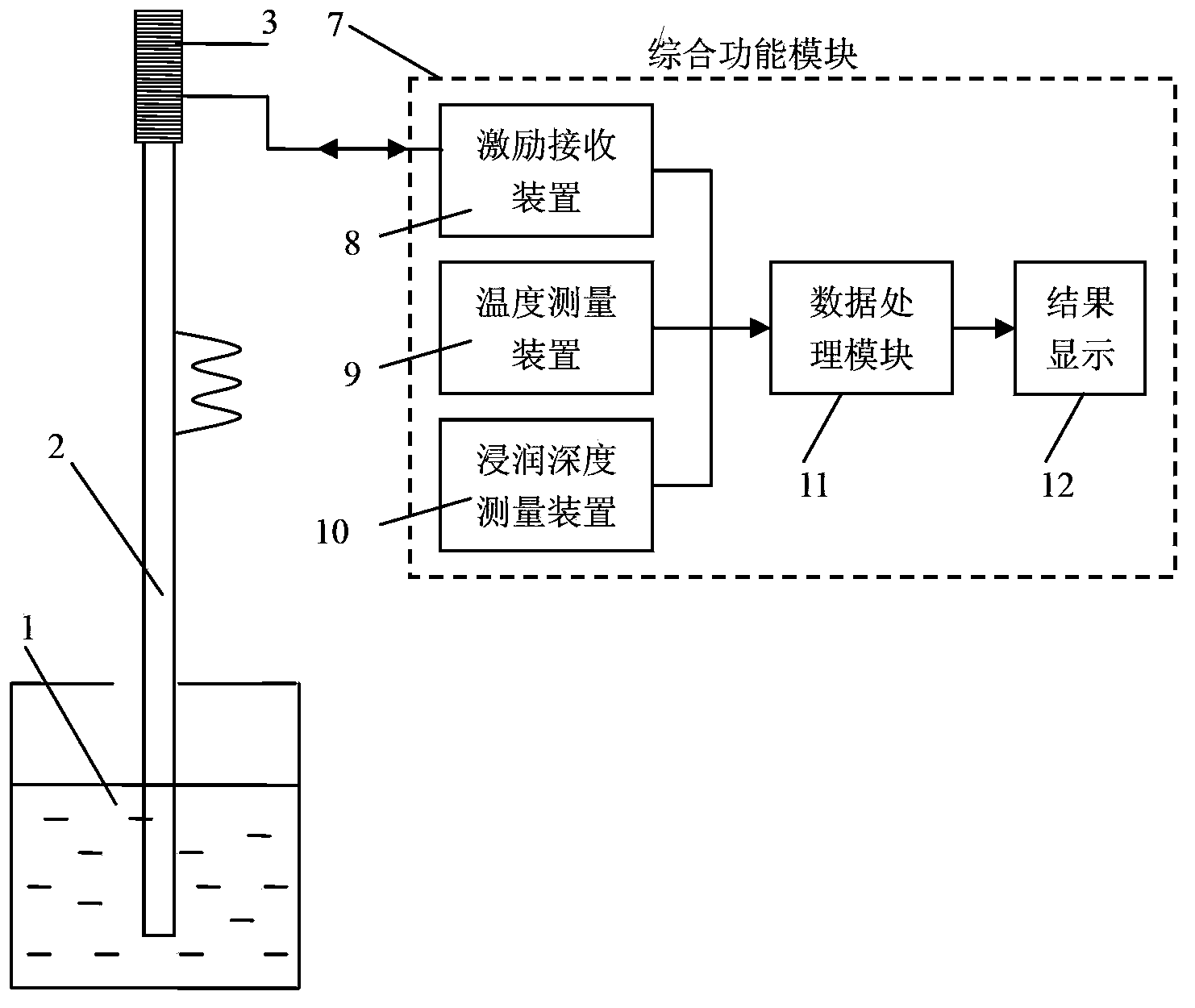

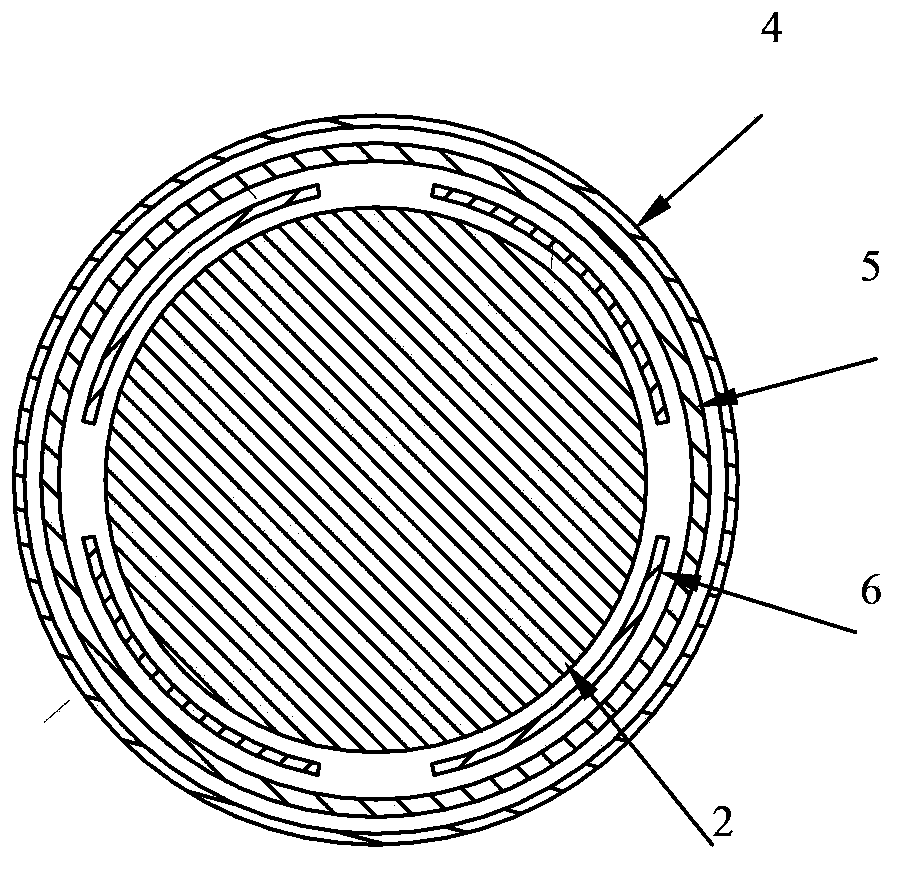

[0020] The detection system device of the present invention is composed of a metal probe rod 2 , a magnetostrictive sensor 3 and a comprehensive functional module 7 . The core of the detection device is the installation and manufacture of the detection probe. figure 2 The fabrication and installation of the probe will be described in detail. The detection probe is composed of the metal probe rod and the magnetostrictive sensor in the device. The overall structure is divided into 4 layers. The first layer is the metal probe rod 2 itself, and the second layer is the iron-cobalt belt 6. The cobalt tape is cut into four sections of the same size and shape and placed symmetrically on the surface of the probe rod, then put on the third layer of plastic sleeve 5, and use epoxy glue to fix the three together, and finally wind the coil on the sleeve and fixed.

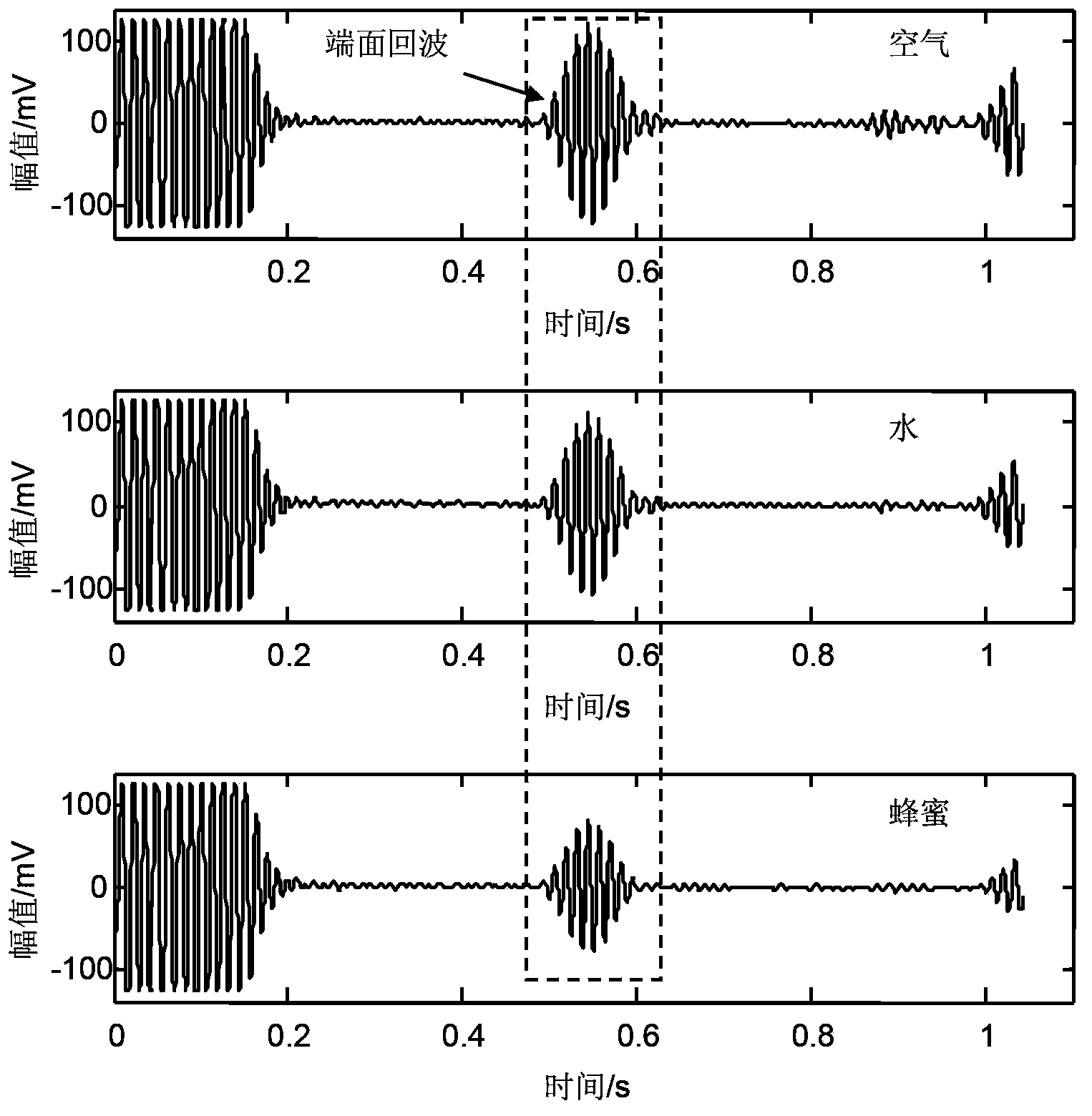

[0021] The specific implementation of the detection method can be divided into two types: one is to measure the viscosity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com