Method and apparatus for testing flow injection ammonia nitrogen color comparison

A detection method and flow injection technology, which is applied in the field of flow injection ammonia nitrogen colorimetric detection, can solve the problems of toxic reagents, cumbersome operation, and inability to store reagents for a long time, and achieve the effects of non-toxic reagents, small reagent volume, and simple and fast detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

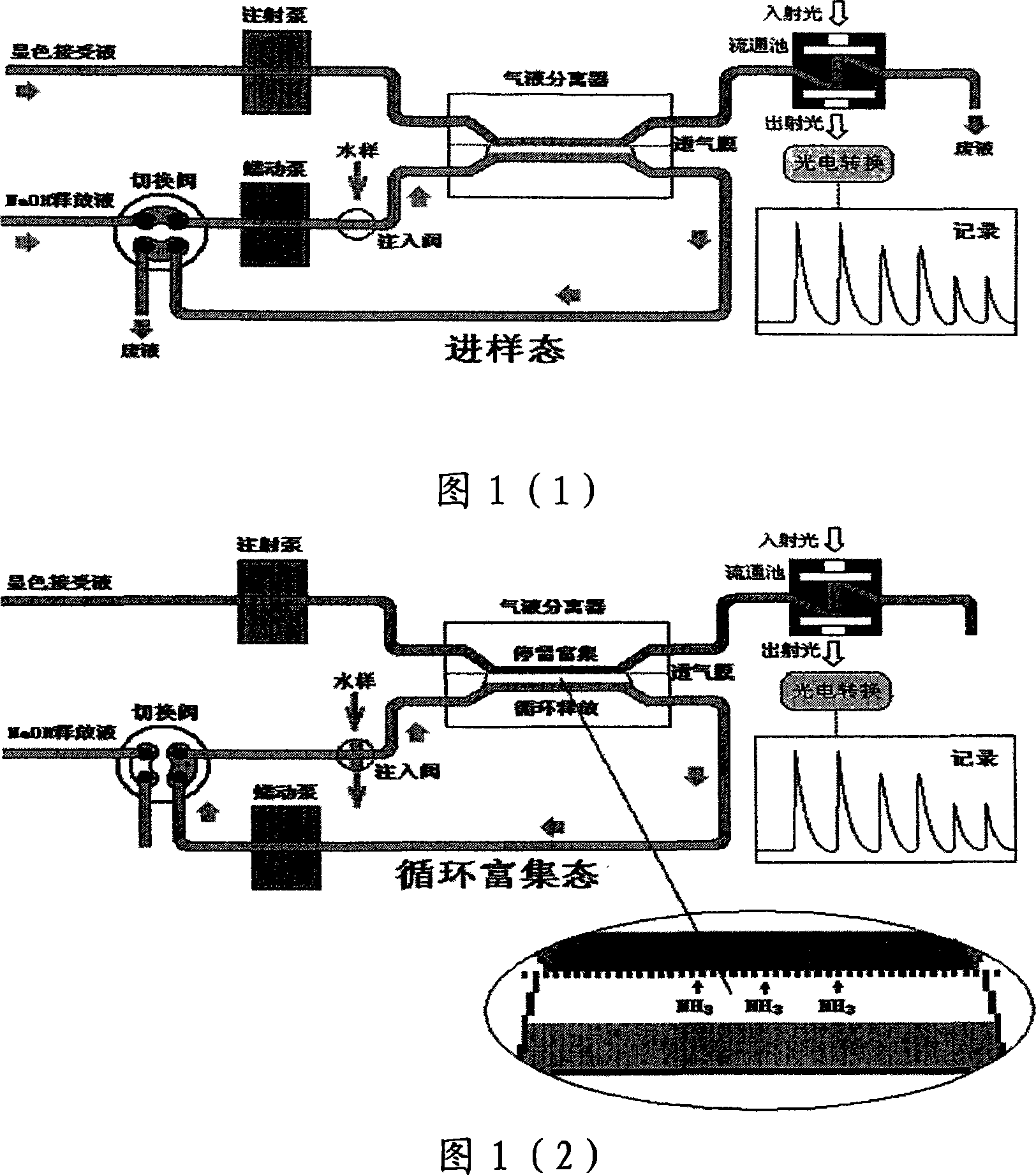

[0033] The implementation process and operation process of the flow injection ammonia nitrogen colorimetric detection method will be described below in conjunction with FIG. 1 (1).

[0034] The ammonia nitrogen detection principle of this detection method is shown in Figure 1 (1) and Figure 1 (2).

[0035] Both Fig. 1(1) and Fig. 2(2) show that the upper part is the capillary pipeline system of the chromogenic receiving liquid, and the lower part is the capillary pipeline system of the releasing liquid, and the two are connected by a gas-liquid separator.

[0036] Figure 1 (1) shows that the system is in the sampling state, and the receiving liquid is injected into the capillary by the syringe pump and passed into the flow cell through the capillary groove on the upper part of the gas-liquid separator (located above the gas-permeable membrane), and flows out from the flow cell, so that the acceptor Fluid fills the upper capillary system and the syringe pump stops. On the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com