Method for selecting smoke gas average flow rate measure point of desulfurized flue gas online monitoring system of coal-fired power plant

An average velocity, coal-fired power plant technology, applied in average velocity measurement, measuring device, velocity/acceleration/shock measurement, etc., can solve problems such as instability, large centrifugal force, flow sampling and measurement difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

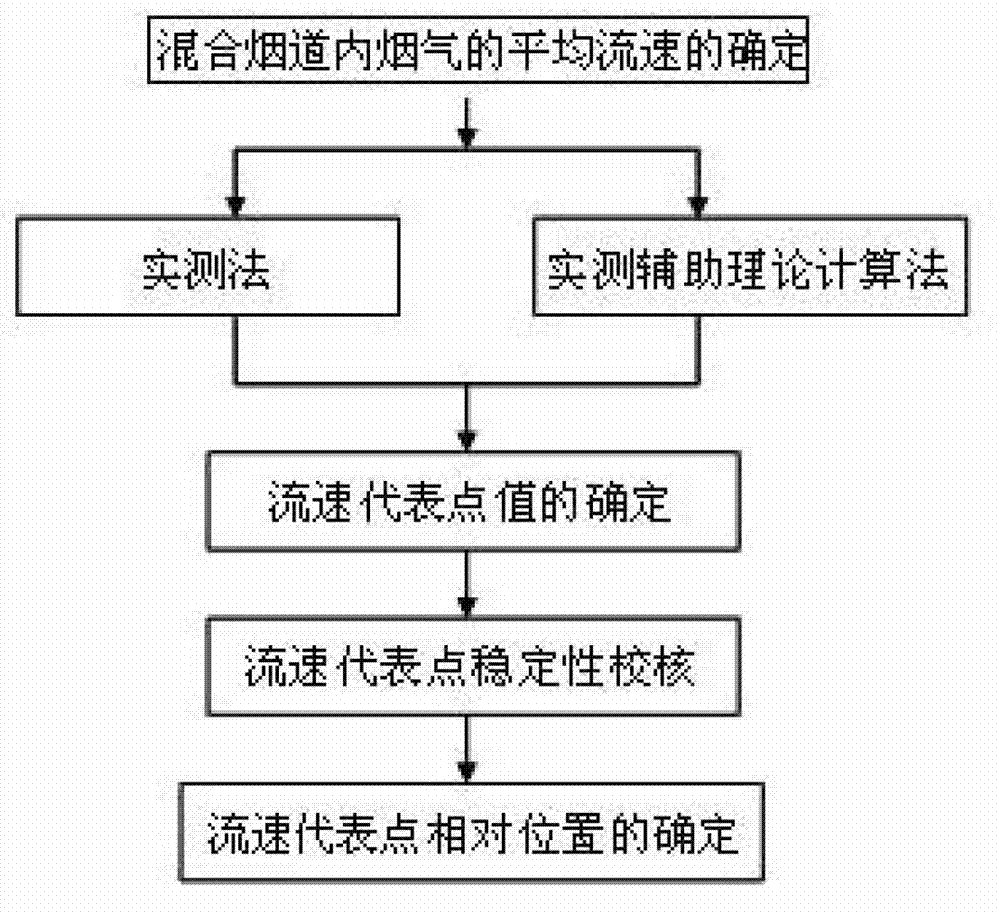

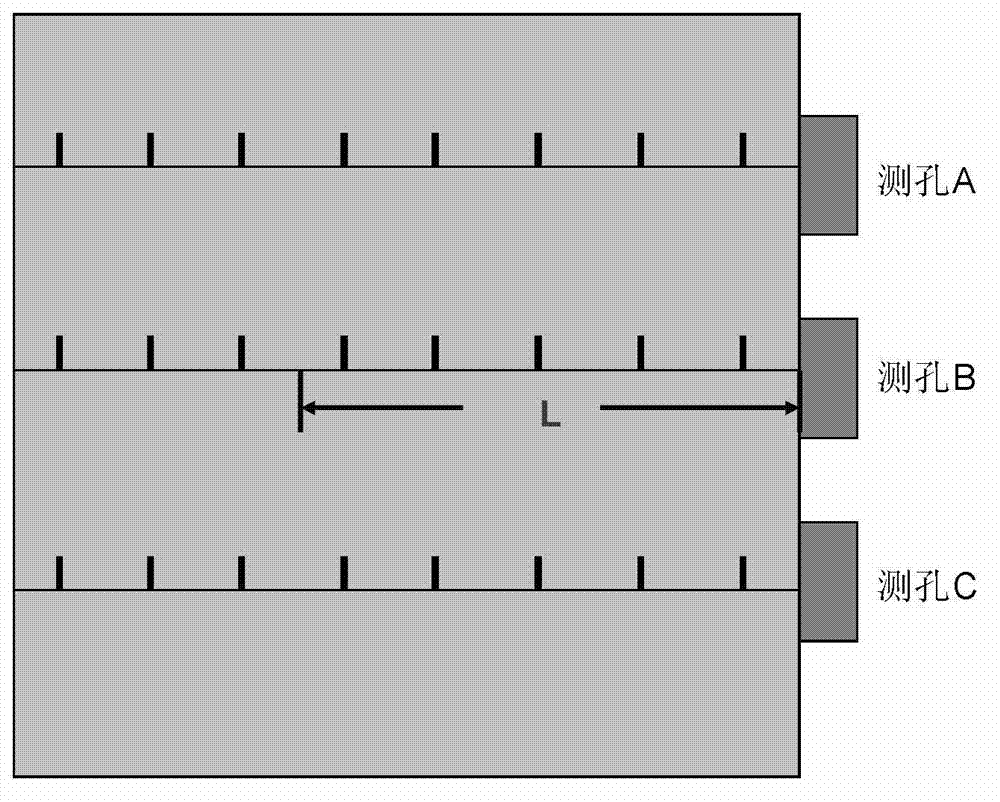

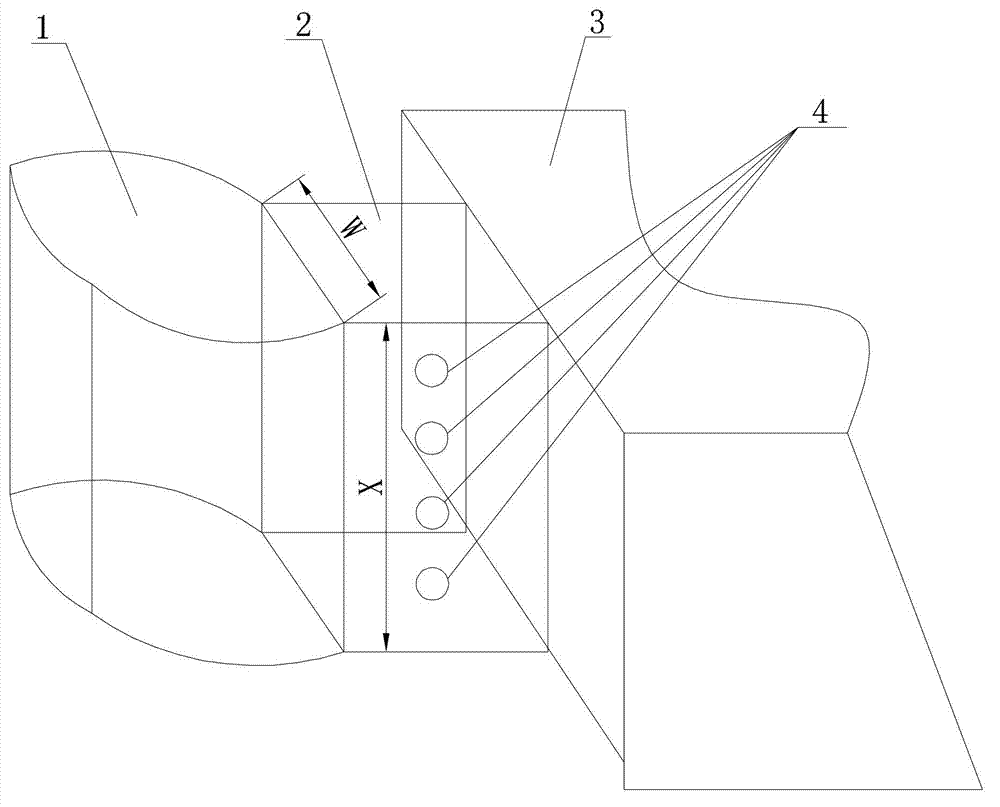

[0125] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, the specific steps of the method for selecting the average flow rate measuring point of flue gas in the coal-fired power plant desulfurization flue gas online monitoring system in this embodiment are:

[0126] Step 1. The grid method is used to determine the average flow velocity of the flue gas in the mixed flue, and the flow velocity V of the wet flue gas at the measuring point of the mixed flue s混 It can be obtained according to formula (1):

[0127]

[0128] Among them: K p is the standard Pitot tube correction coefficient, K p =1.0;P d混 is the dynamic pressure, Pa; ρ s混 is the density of wet flue gas in the mixed flue, kg / m 3 ,

[0129] The wet flue gas density ρ of the mixed flue in formula (1) s混 Calculate according to formula (2):

[0130]

[0131] where: ρ n混 is the density of wet smoke under standard conditions, kg / m 3 ; T s is the flue gas temperature,...

specific Embodiment approach 2

[0172] Specific implementation mode two: combination Figure 1-Figure 3 To illustrate this embodiment, the specific steps of the method for selecting the average flow rate measuring point of flue gas in the coal-fired power plant desulfurization flue gas online monitoring system in this embodiment are:

[0173] Step 1. Determine the average flow velocity of flue gas in the mixed flue,

[0174] Calculate the flue gas volume flow Q under the actual state of the outlet of the dust collector 1 ,

[0175] Q 1 = 3600 × F 1 × V 1 ‾ - - - ( 1 )

[0176] Where: F 1 is the cross-sectional area of the flue at the outlet of the dust collector, m 2 ; is the average flow velocity at the outlet of the dust collector, m / s, It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com