Locomotive resistance box

A resistance box and resistance technology, applied in the direction of resistors, electric vehicles, electrical components, etc., can solve the problem of easy burning of resistance boxes, and achieve the effect of reducing material consumption, reducing volume, and balancing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

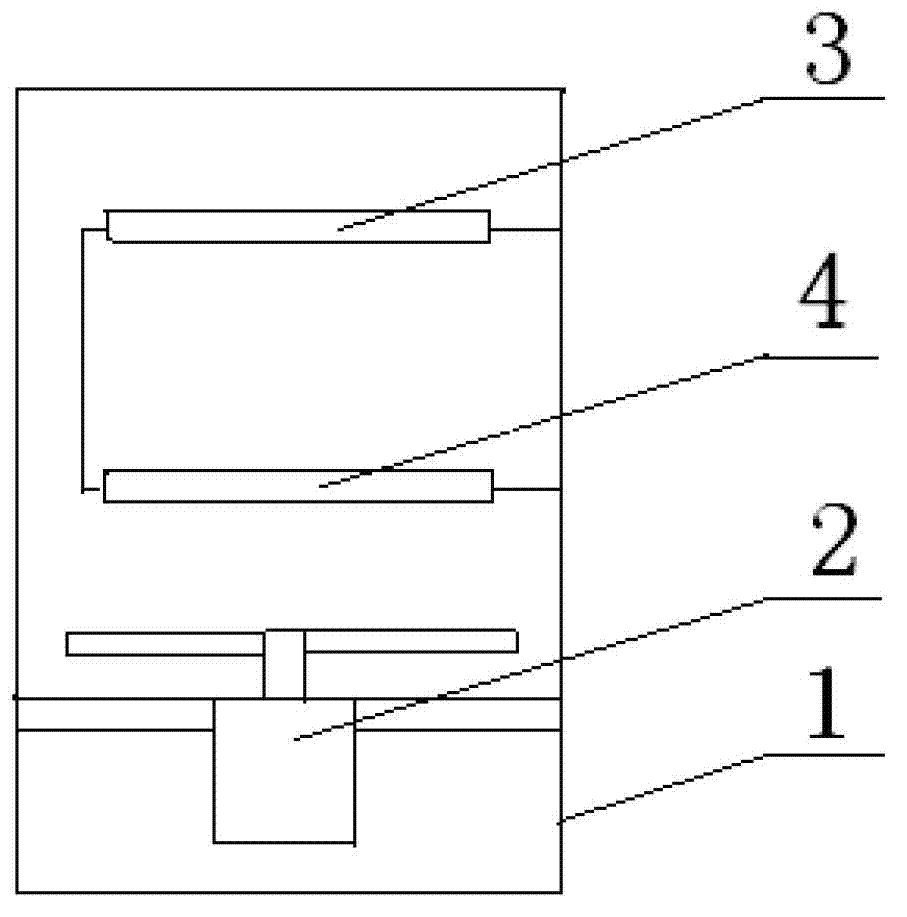

[0015] This embodiment discloses a locomotive resistance box, the appearance of which is the same as that of the existing locomotive resistance box structure, such as figure 1 As shown, it includes box 1, ventilator 2 and two resistance bands in series (the first resistance band and the second resistance band). , are respectively the first resistance surface 3 and the second resistance surface 4, the first resistance surface 3 and the second resistance surface 4 are parallel to each other, and are fixed in the box body 1; the fan 2 is fixed close to the second resistance surface 4 and away from the first resistance surface In the box on one side of the resistance surface 3, the air outlet direction of the fan 2 is perpendicular to the plane where the resistance surface (the first resistance surface 3 and the second resistance surface 4) is located. When the fan 2 is working, the air can be blown to the second A resistance surface 3 and a second resistance surface 4; the resist...

Embodiment 2

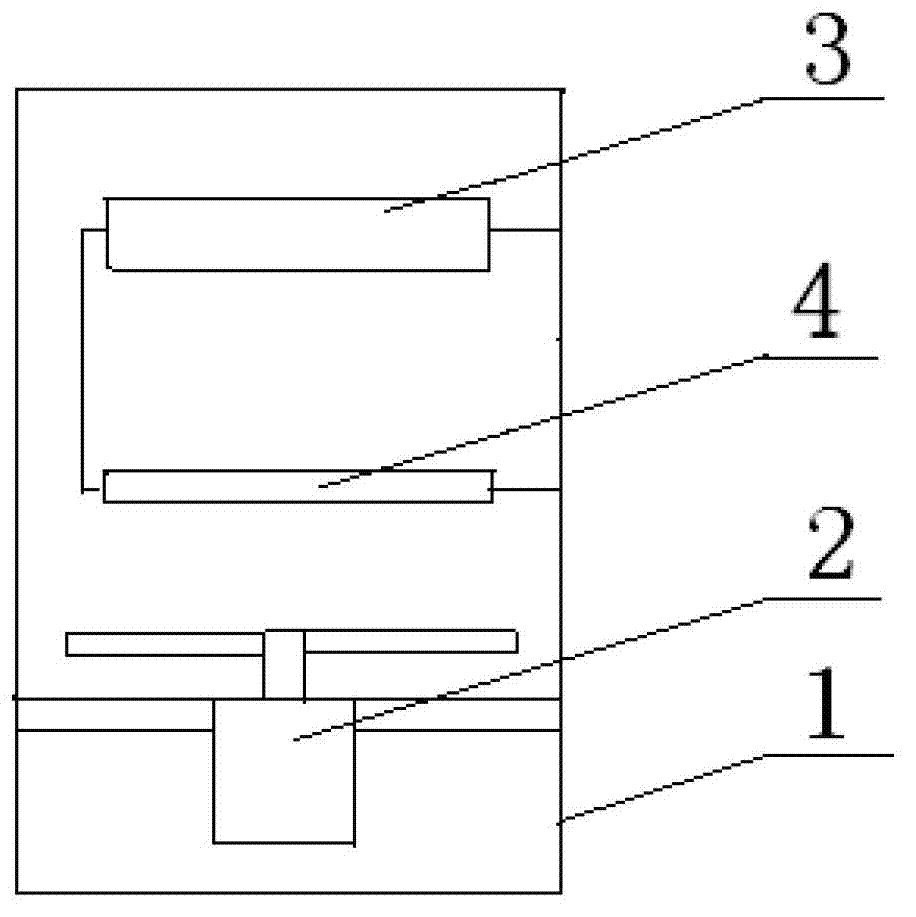

[0023] figure 2 It is a schematic structural diagram of the locomotive resistance box provided in Embodiment 2.

[0024] This embodiment discloses a locomotive resistance box, such as figure 2 As shown, the locomotive resistance box includes a box body 1, a ventilator 2 and two resistance bands connected in series. 4. The first resistance surface 3 and the second resistance surface 4 are parallel to each other and fixed in the box body 1; the fan 2 is fixed in the box body 1 close to the side of the second resistance surface 4 away from the first resistance surface 3 for ventilation The air outlet of the fan 2 is perpendicular to the plane where the resistance surface is located. When the fan 2 is working, the air outlet can blow to the first resistance surface 3 and the second resistance surface 4 at the same time; the resistance value of the resistance band of the second resistance surface 4 > the first The resistance value of the resistance band of the resistance surfac...

Embodiment 3

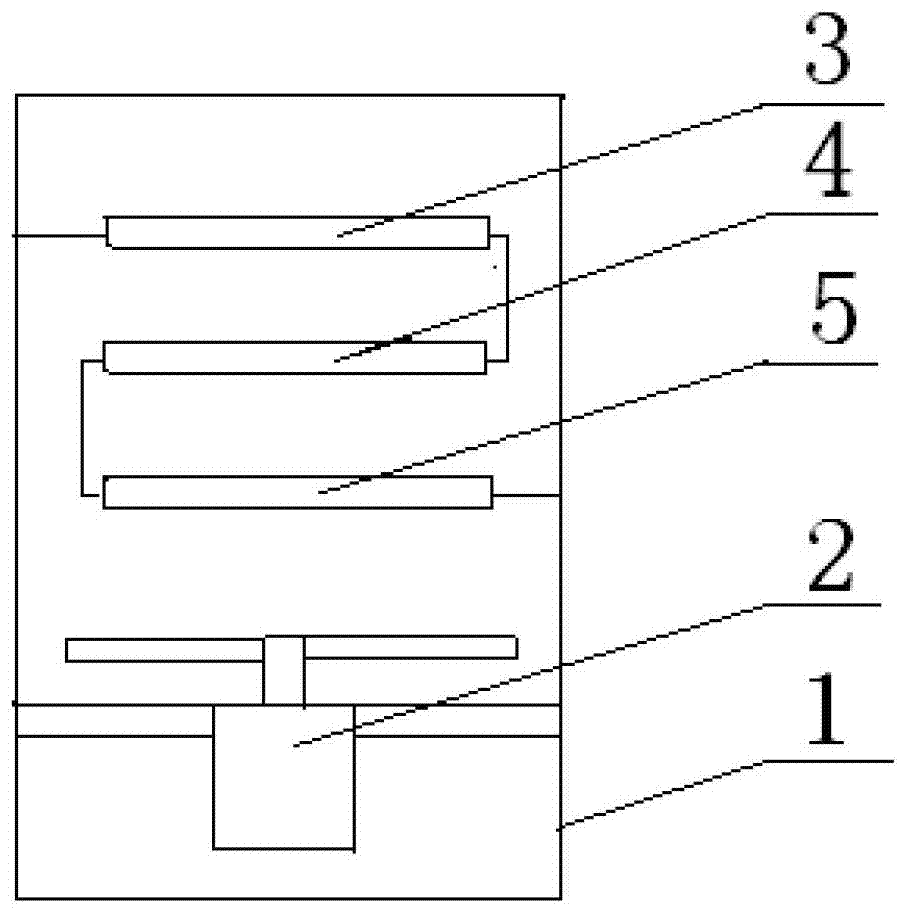

[0028] image 3 It is a schematic structural diagram of the locomotive resistance box provided in Embodiment 3.

[0029] This embodiment discloses a locomotive resistance box, such as image 3 As shown, the difference from Embodiment 1 is that the locomotive resistance box includes three resistance bands in series, and the three resistance bands are serpentinely wound into three resistance surfaces with gaps, which are respectively the first resistance surface 3 and the second resistance surface 4. The third resistance surface 5.

[0030]The ventilator 2 is fixed in the box body 1, and its vent faces the third resistive surface 5. When the ventilator 2 is working, its air outlet can blow to the first resistive surface 3 and the second resistive surface 4 at the same time; The resistance faces the direction away from the resistance surface of the ventilator 2, and the resistance value of the resistance band decreases gradually. The length and cross-sectional area of each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com