Microporous metal cooling mirror and production method thereof

A metal cooling and microporous technology, applied in laser parts, electrical components, phonon exciters, etc., can solve the problems of difficult to ensure the heat dissipation capacity and surface shape of mirrors, difficult to control the distribution and size of micropores, etc., to achieve easy operation. , The method is simple, the effect of reducing the contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

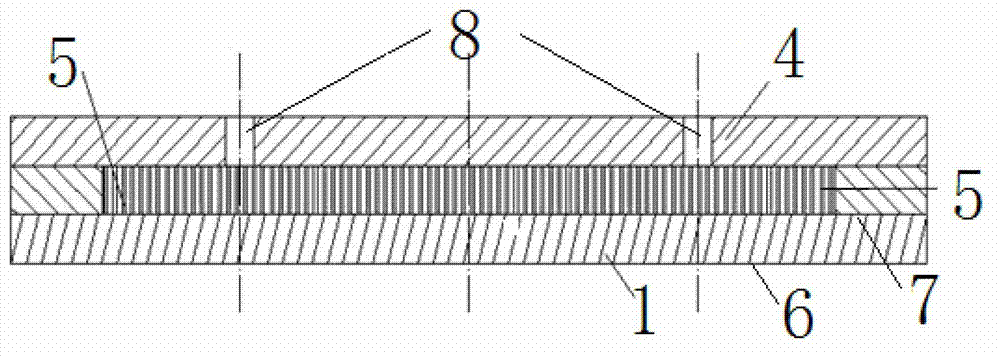

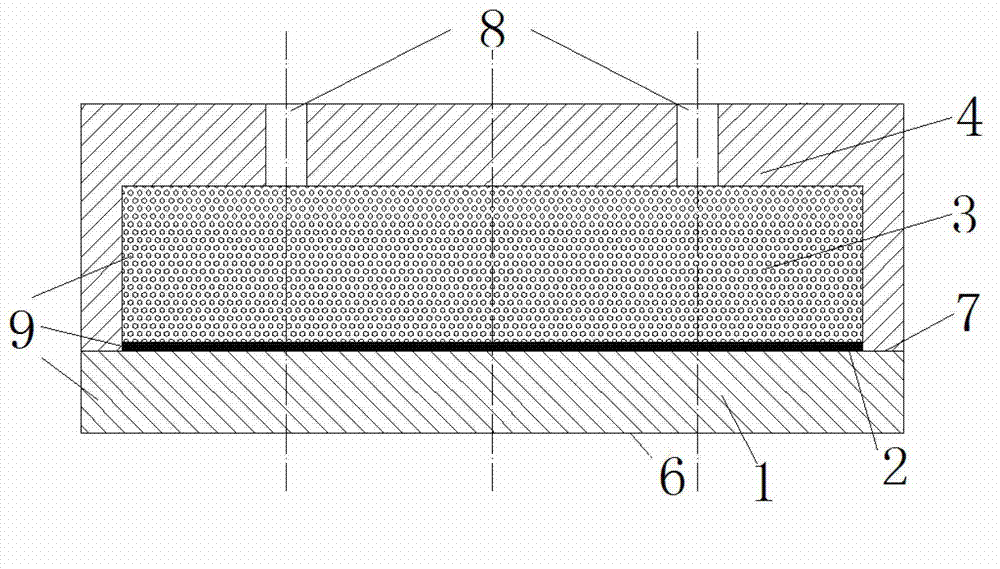

[0026] Example 1: Take foamed Cu as the foamed metal microporous layer material, and Si as the mirror surface material

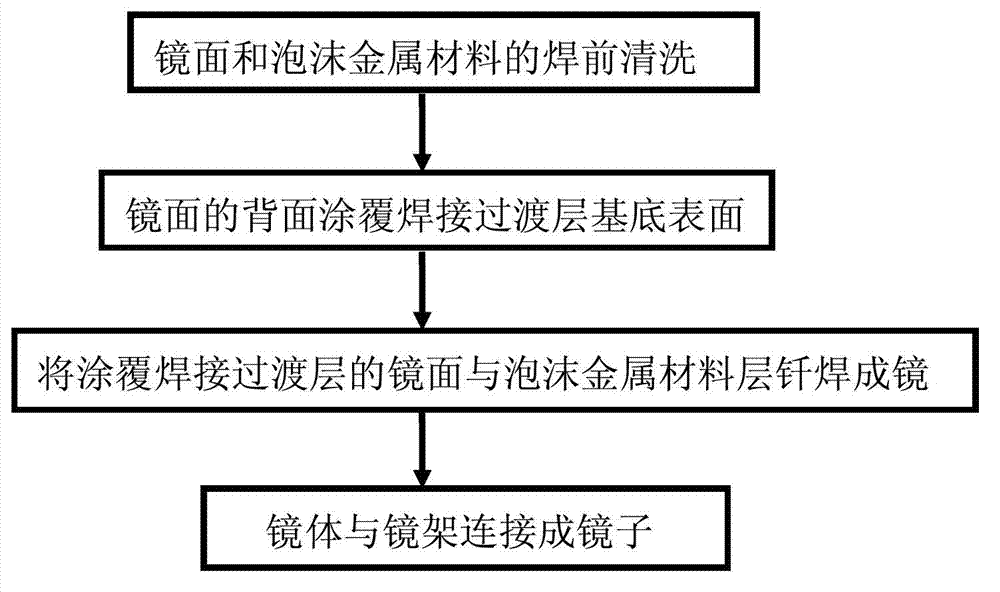

[0027] Step 1: Clean the foamed Cu material with a pore size of 10 μm and a porosity of 95% and the Si mirror;

[0028] Step 2: plating a transition layer with a thickness of 500nm on Si, wherein the first layer is Cr with a thickness of 200nm, and the second layer is Ag with a thickness of 300nm;

[0029] Step 3: Brazing the Si coated with the transition layer and Cu foam to form a mirror body. The brazing temperature is 1000℃, and the welding time is 2h;

[0030] Step 4: Connect the welded mirror body and the mirror frame together with screws, and the connected mirror must not leak.

example 2

[0031] Example 2: Take foamed Cu as the foamed metal microporous layer material, and Mo as the mirror surface material

[0032] Step 1: cleaning foamed Cu and Mo with a pore size of 10mm and a porosity of 10%;

[0033] Step 2: There is no need to apply a transition layer due to the good wettability between Mo and Cu. The Mo mirror surface is brazed with foamed copper, the welding temperature is 1000°C, and the welding time is 5h;

[0034] Step 3: Connect the welded mirror body and mirror frame together with screws, and the connected mirror must not leak.

example 3

[0035] Example 3: Using Ni foam as the metal foam microporous layer material, W as the mirror surface material

[0036] Step 1: Clean the foamed Ni and W mirror surfaces with a pore size of 100 μm and a porosity of 60%;

[0037] Step 2: There is no need to apply a transition layer due to the good wettability between W and Ni. Weld the W mirror surface with the Ni foam, the welding temperature is 2000°C, and the welding time is 130h;

[0038] Step 3: Connect the welded mirror body and mirror frame together with screws, and the connected mirror must not leak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com