Super-high-speed electric main shaft sealing structure adopting water lubricating static pressure bearing

A technology of dynamic and static pressure bearings and high-speed electric spindles, which is applied to metal processing equipment, etc., can solve problems such as unreliable sealing and unsatisfactory sealing effects, and achieve the effects of reliable sealing, ingenious design, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

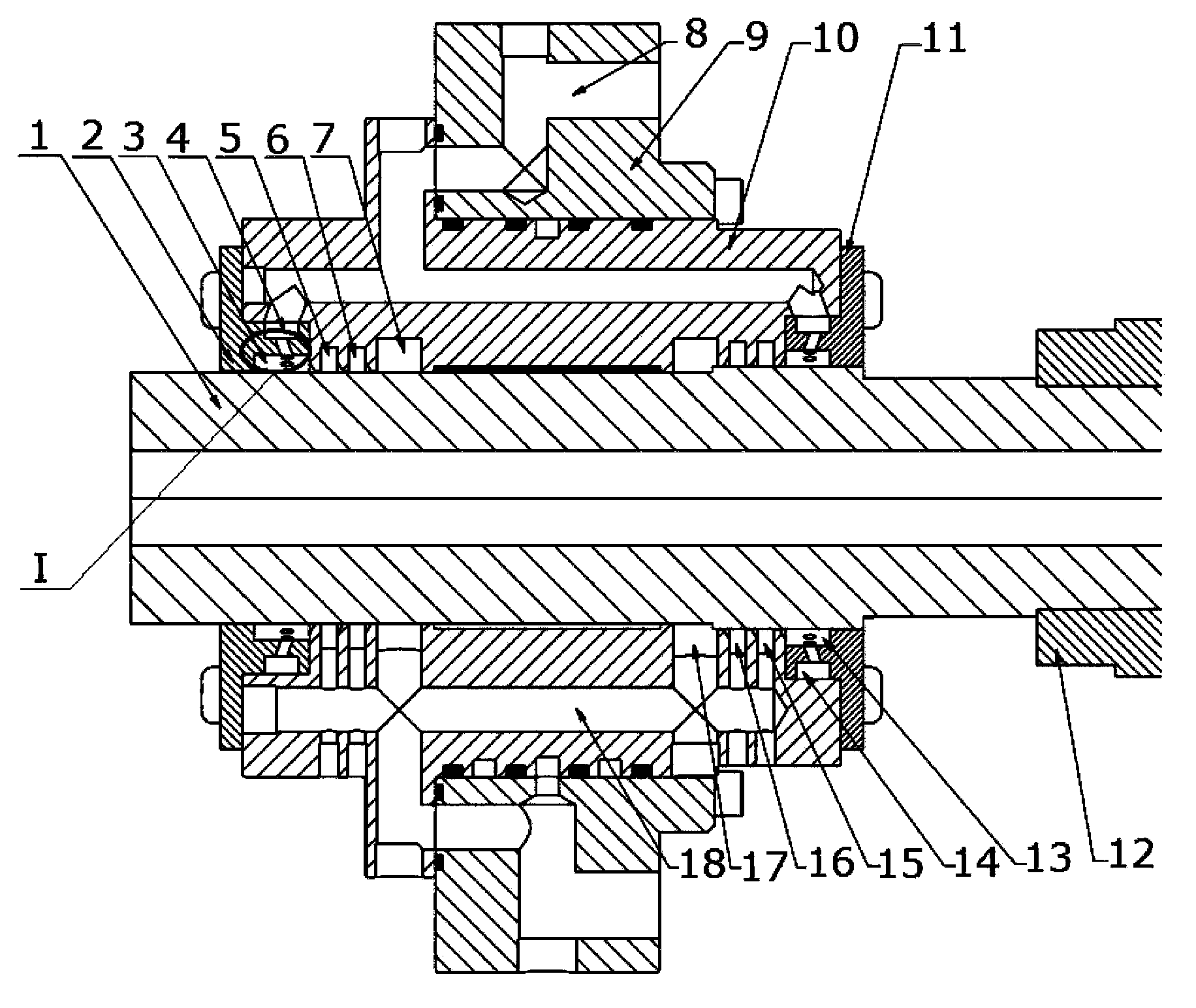

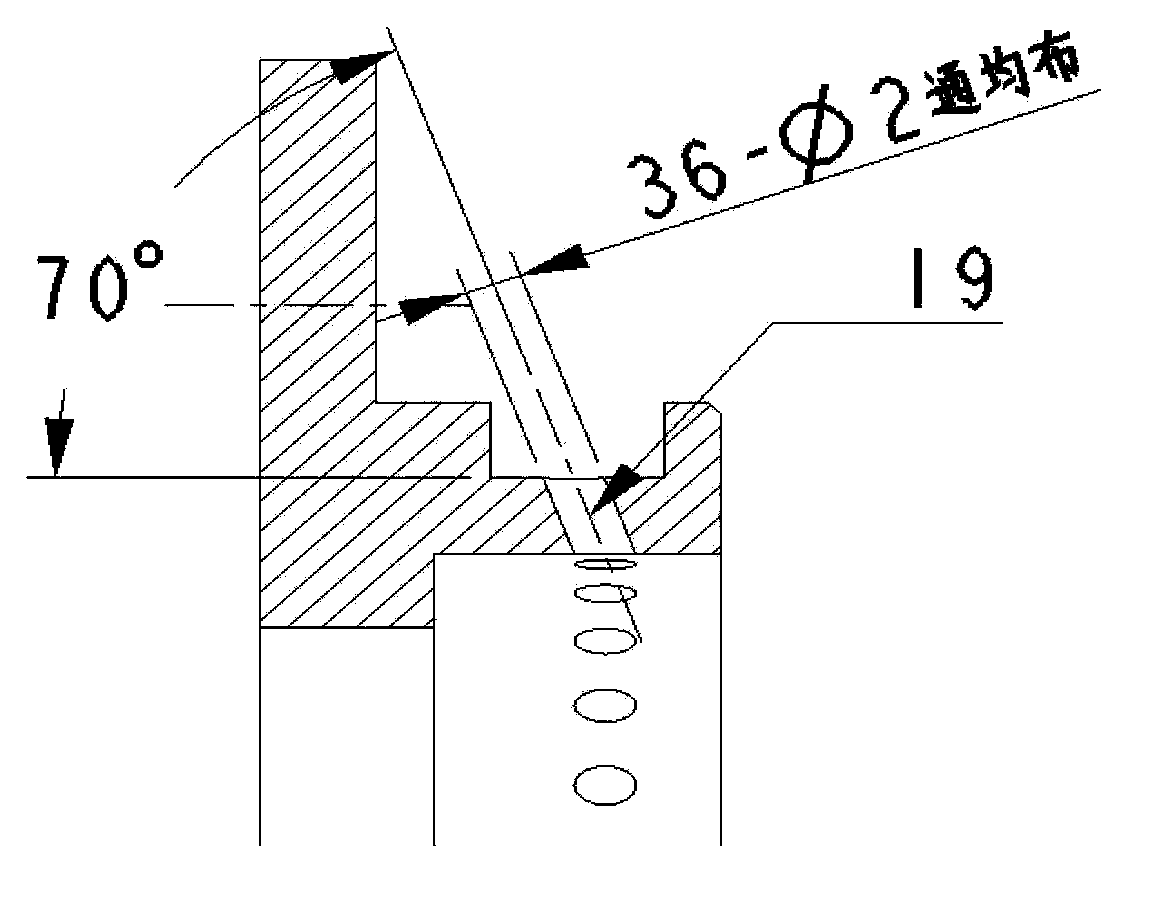

[0014] Such as figure 1 As shown, in the water-lubricated bearing sealing structure of the electric spindle of the present invention, the sliding bearing 10 is sleeved on the electric spindle 1 extending from the motor rotor 12, and the electric spindle 1 at the two ends of the sliding bearing 10 is sleeved with front and rear symmetrical air seal covers 2 , 11, and fastened with the sliding bearing 10, the sliding bearing is provided with an air inlet channel 8 and a drain channel 18. On the axial ends of the inner wall of the sliding bearing 10, there are symmetrical annular primary water return grooves 7, 17, the outer side of the annular primary water return groove 7, 17 is provided with annular secondary water return grooves 8, 16 and the outer side of the annular secondary water return groove 8, 16 is provided There are annular three-stage return water tanks 9, 15; the three-stage front and rear annular return water tanks are connected by a drainage channel 18 to discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com