Forming method of rotatably overlaying swirler

A molding method and cyclone technology, which are applied in the field of mechanical processing, can solve the problems of reducing the technological requirements required for molding, complex processing methods of the cyclone, high processing equipment and technical requirements, and achieve the effect of improving efficiency and saving processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

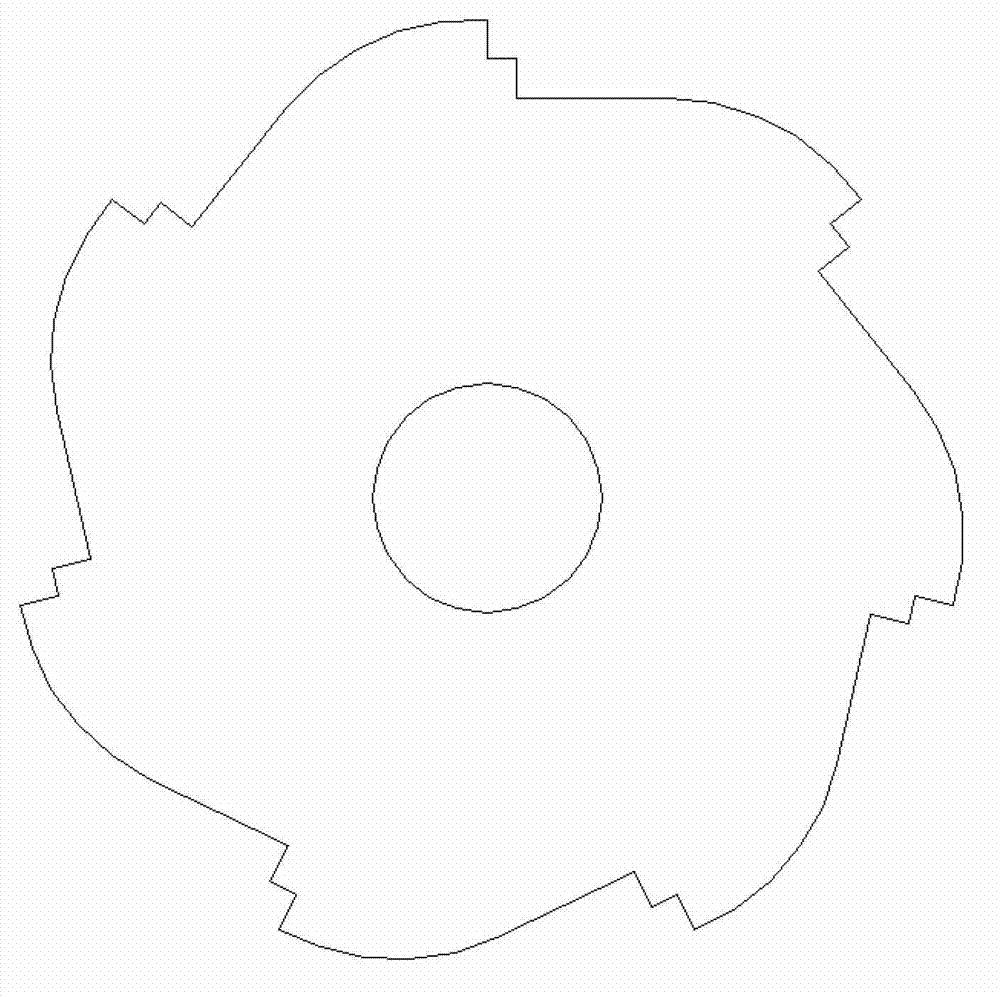

[0041] Step 1, use wire cutting to process two impellers with the same blade shape, such as figure 2 shown. Considering that two pieces are overlapped, since the total number of blades is 14, the number of blades of a single impeller is 7. The outer diameter end of each blade protrudes about 2mm from the fixing end 5 for final fixing welding.

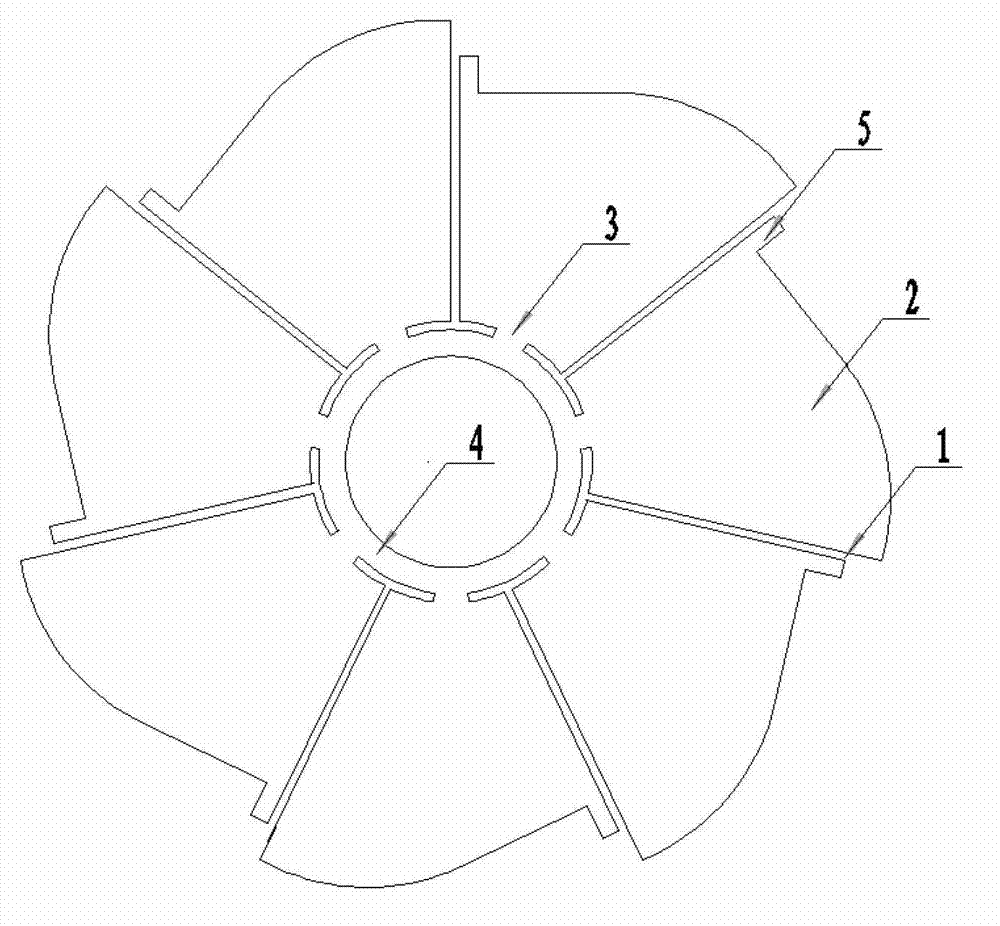

[0042] Step 2: Carry out EDM cutting on the two leaf shapes respectively to process gaps and joints.

[0043] Use electric spark cutting to cut a gap of 0.5mm between two adjacent blades (determined by the diameter of the swirler) 1, and then use electric spark cutting to cut off the unnecessary part of the blade 2 and the inner fixing frame 4, and the remaining connection at 3, such as image 3 shown.

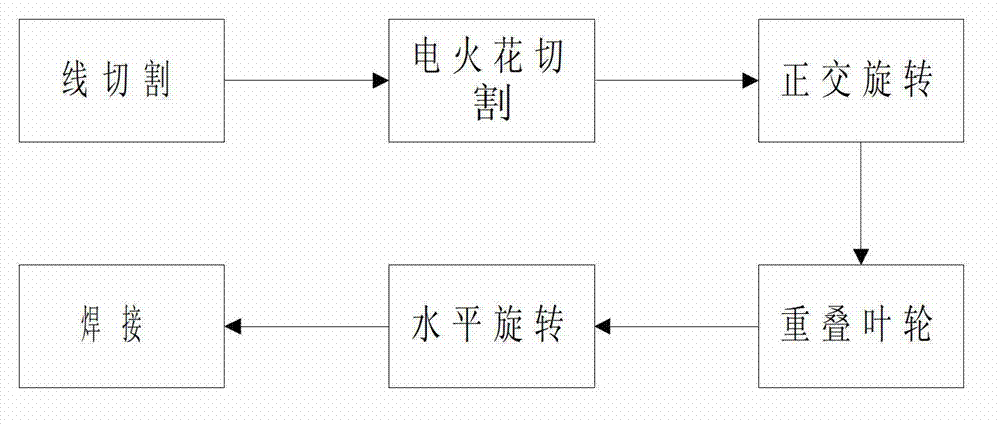

[0044] Step 3, Orthog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com