Novel extraction technology in process of preparing hydrogen peroxide by anthraquinone process

A technology of hydrogen peroxide and anthraquinone method, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc. The impact of materials, the influence of extraction mass transfer is not considered, and the extraction process is unfavorable for mass transfer, etc., to achieve the effect of reducing hydrogen peroxide content, saving power consumption, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

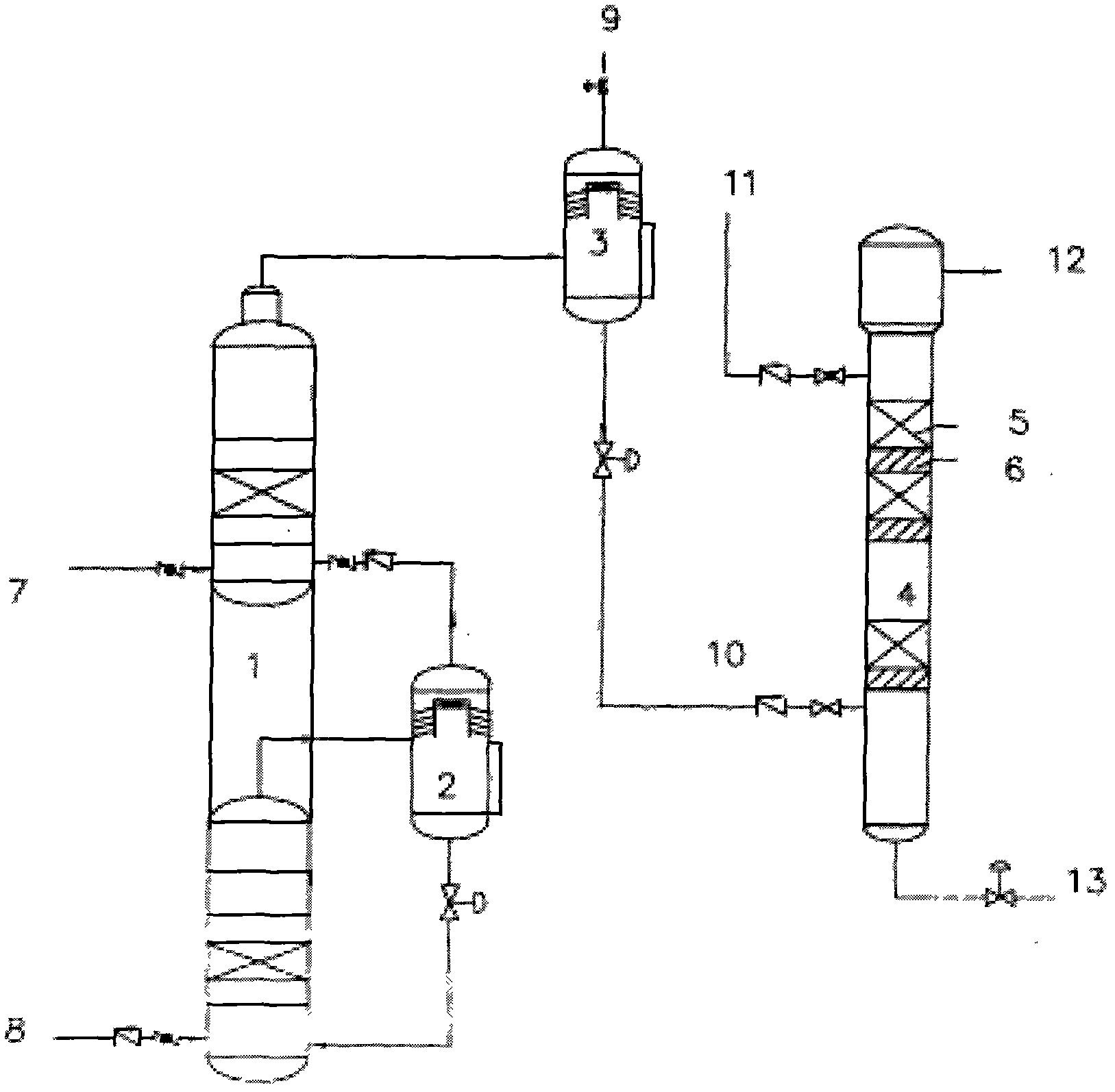

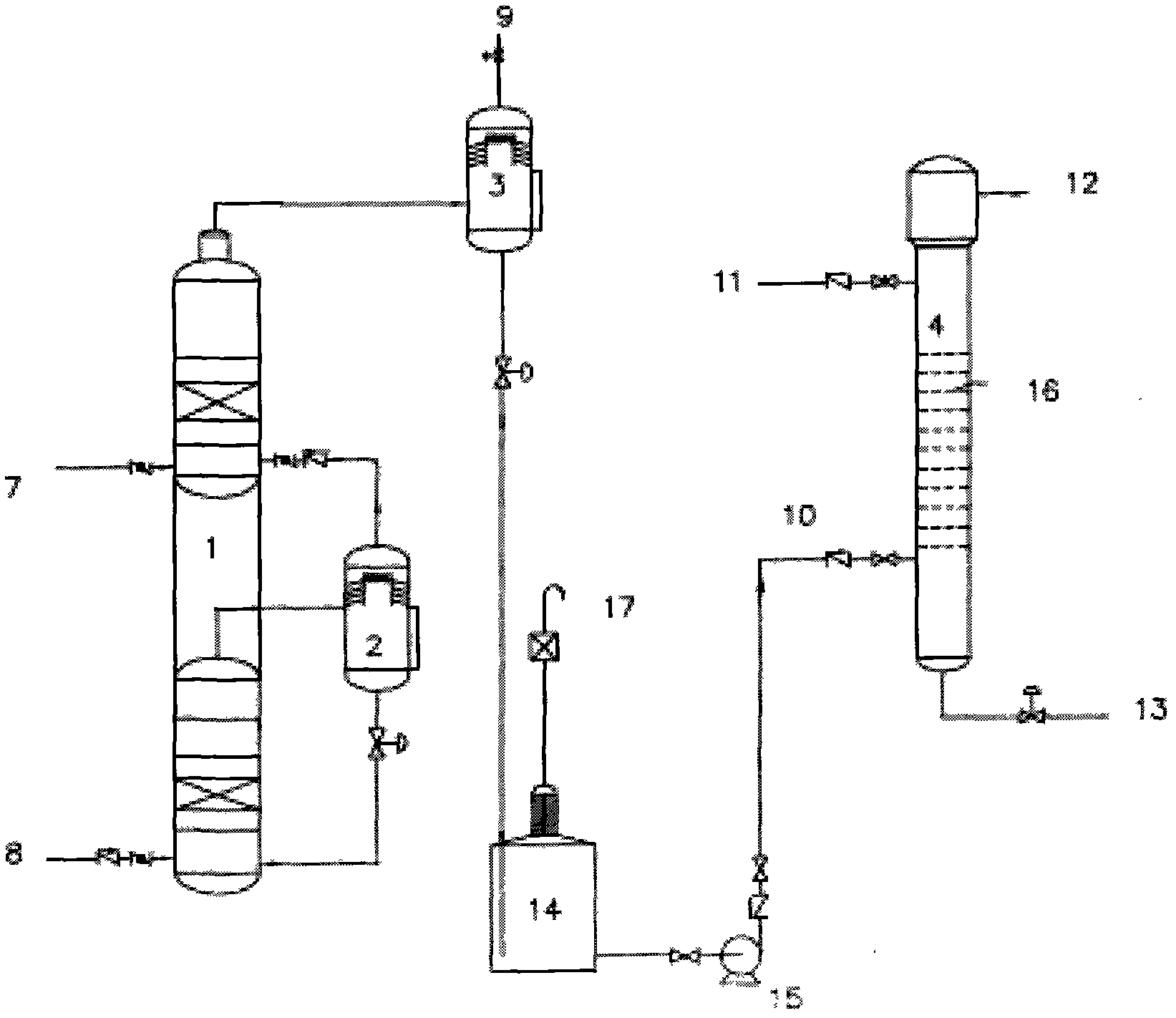

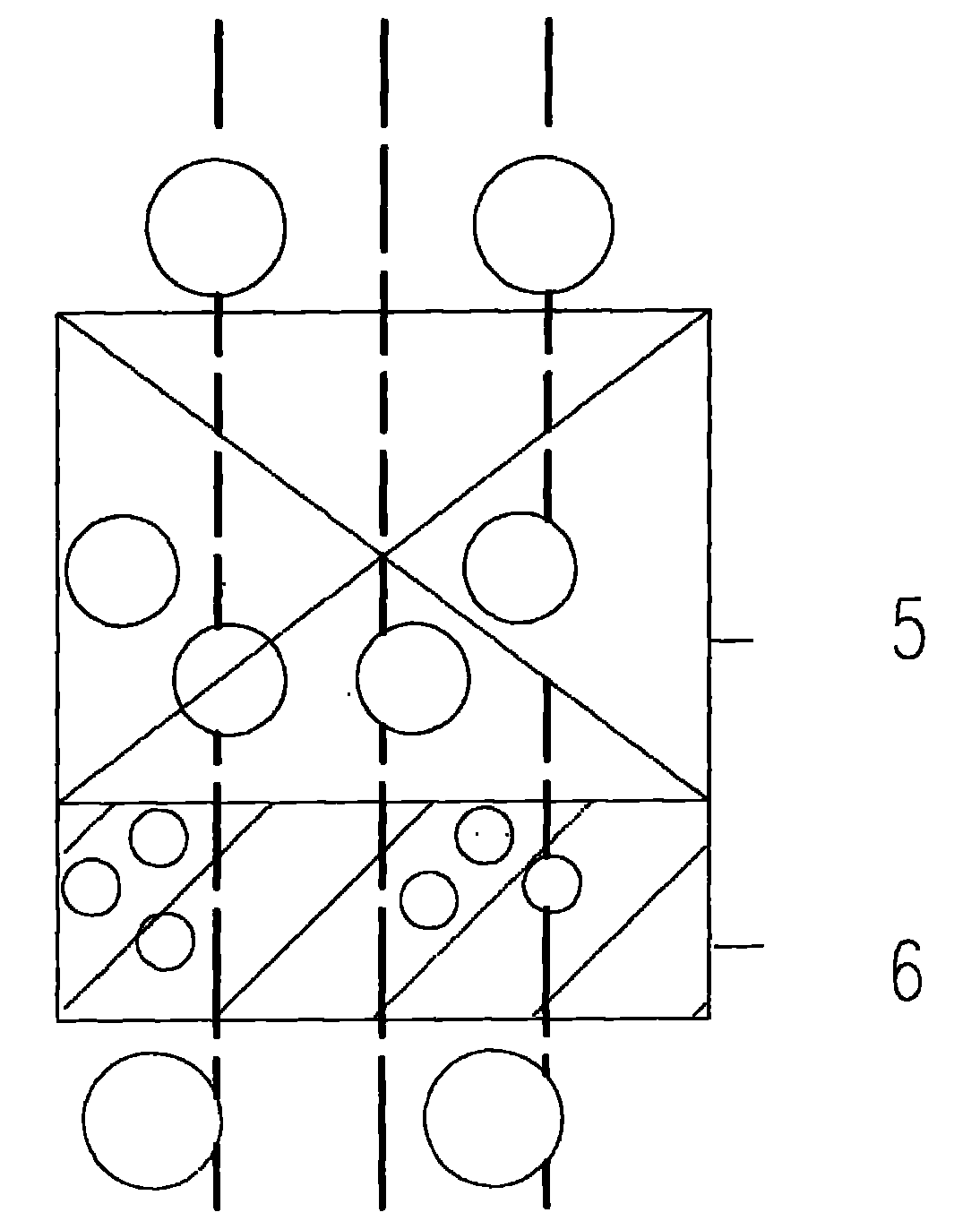

[0043] combined with figure 1 And attached image 3 The technical solution of Embodiment 1 is described.

[0044] The hydrogenated liquid enters the oxidation tower 1 from the inlet 7, and the air enters the oxidation tower 1 from the inlet 8. After the reaction, it finally reaches the oxidation gas-liquid separator 3. The air enters the tail gas treatment unit from the oxidation tail gas vent 9, and the oxidation completion liquid (including hydrogen peroxide) enters the oxidation tower 1 from the oxidation exhaust port 9. The liquid inlet 10 enters the extraction tower 4. Because its density is lower than that of water, it first passes through the dispersed packing layer 6 as a dispersed phase from bottom to top, and then enters the coalescing packing layer 5. The cycle repeats, and the hydrogen peroxide in the working liquid is continuously Water extraction, finally leaves the extraction tower 4 from the raffinate phase (working liquid) outlet 12; deionized water enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com