Preparation method and application of polypyrrole nanometer microspheres

A technology of polypyrrole nano- and microspheres, which is applied in the field of green preparation of polypyrrole microspheres, can solve the problems of unsatisfactory nanostructure and performance, and achieve the effect of large-scale commercial production, simple process conditions and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Measure 0.5ml of pyrrole monomer and put it in a 100ml round bottom flask, then add 50ml of H 2 O, and then add 0.05g FeCl to it 2 , after stirring evenly by magnetic force, add 4ml H 2 o 2 , and the reaction was stirred at 25°C for 24 hours. After the reaction is finished, wash and filter with acetone, and then dry in a vacuum oven at 60° C. for 24 hours to obtain polypyrrole powder.

Embodiment 2

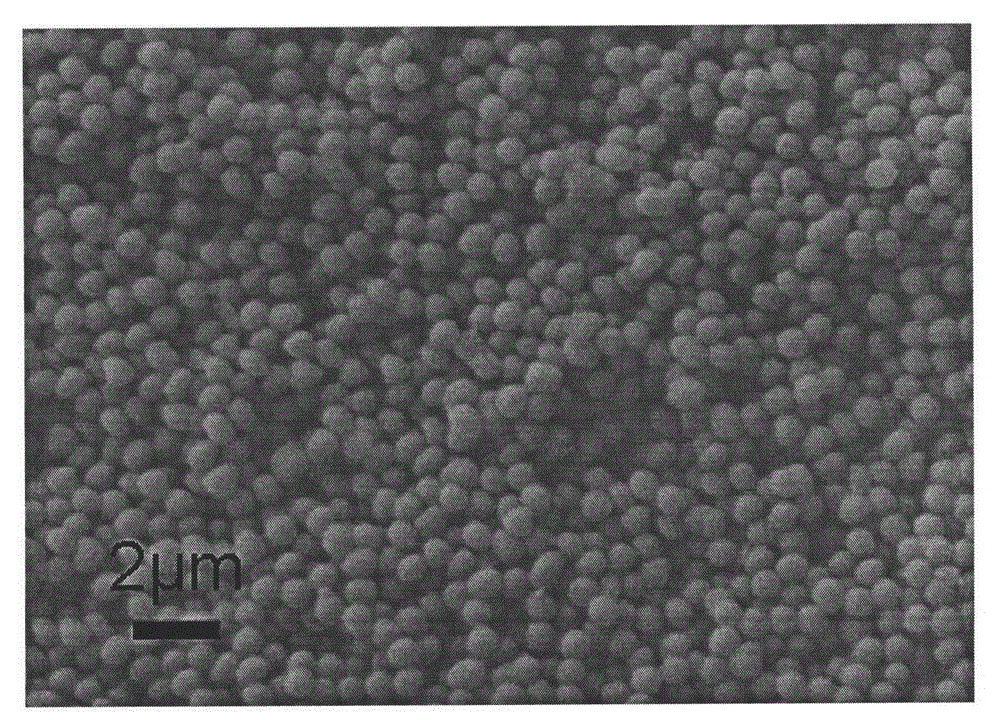

[0022] Measure 1ml of pyrrole monomer and put it in a 250ml round bottom flask, then add 80ml of H 2 O, and then add 0.05g FeCl to it 2 , after stirring evenly by magnetic force, add 8ml H 2 o 2 , Stir the reaction at -5°C for 36 hours. After the reaction is finished, wash and filter with acetone, then dry in a vacuum oven at 60°C for 24 hours to obtain the powder of polypyrrole, the SEM picture of which is as follows: figure 1 shown.

Embodiment 3

[0024] Measure 0.5ml of pyrrole monomer and put it in a 100ml round bottom flask, then add 50ml of H 2 O, and then add 0.1 g FeCl to it 2 , after stirring evenly by magnetic force, then add 1ml H 2 o 2 , and the reaction was stirred at 5°C for 12 hours. After the reaction is finished, wash and filter with acetone, and then dry in a vacuum oven at 60° C. for 24 hours to obtain polypyrrole powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com