High-alkalinity synthetic slag for pipeline steel secondary refining

A technology of synthetic slag and high alkalinity, which is applied in the fields of high-alkalinity synthetic slag for refining outside the furnace, desulfurization of molten steel for pipeline steel and controlled removal of inclusions, which can solve damage, difference in anisotropic performance, and deterioration of plastic section shrinkage of steel and other issues, to achieve the effects of cost reduction, reduced dosage, good melting and flow properties

Inactive Publication Date: 2013-01-09

UNIV OF SCI & TECH BEIJING

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This causes significant differences in the isotropic properties of the product, which deteriorates the plasticity of the steel and the shrinkage of the area along the thickness direction, causing the steel product to be damaged by various complex stresses.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

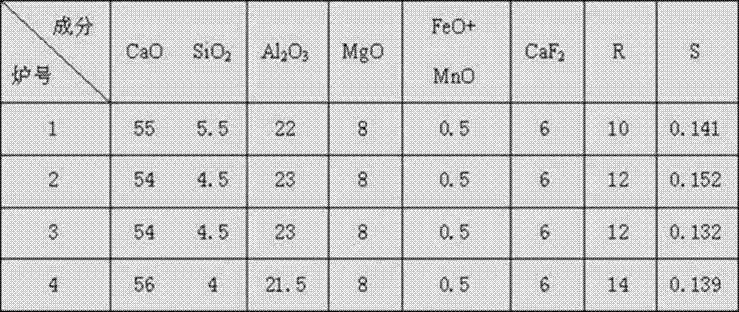

The invention belongs to the technical field of steelmaking, particularly provides a high-alkalinity synthetic slag for pipeline steel secondary refining which is especially suitable for desulfuration of molten pipeline steel and control and removal of occluded substance. Chemical components of the high-alkalinity synthetic slag for the pipeline steel secondary refining specifically include, by weight, CaO 45-60%, Al2O3 15-30%, MgO 6-10%, SiO2 5%, CaF2 5-10%, MnO+FeO 0.6% and initial sulfur capacity in the slag 0.05-0.15%, wherein the alkalinity is 8-15. Compared with traditional synthetic slag for pipeline steel refining, the high-alkalinity synthetic slag has high sulfur capacity (KTH model CS 0.01-0.02). According to the relation of the sulfur capacity, the slag amount and desulfurization rate, the sulfur capacity is higher, the smaller the slag amount required by the same desulfurization rate is. By using the synthetic slag with high sulfur capacity, the refining slag amount can be decreased, and the cost is reduced.

Description

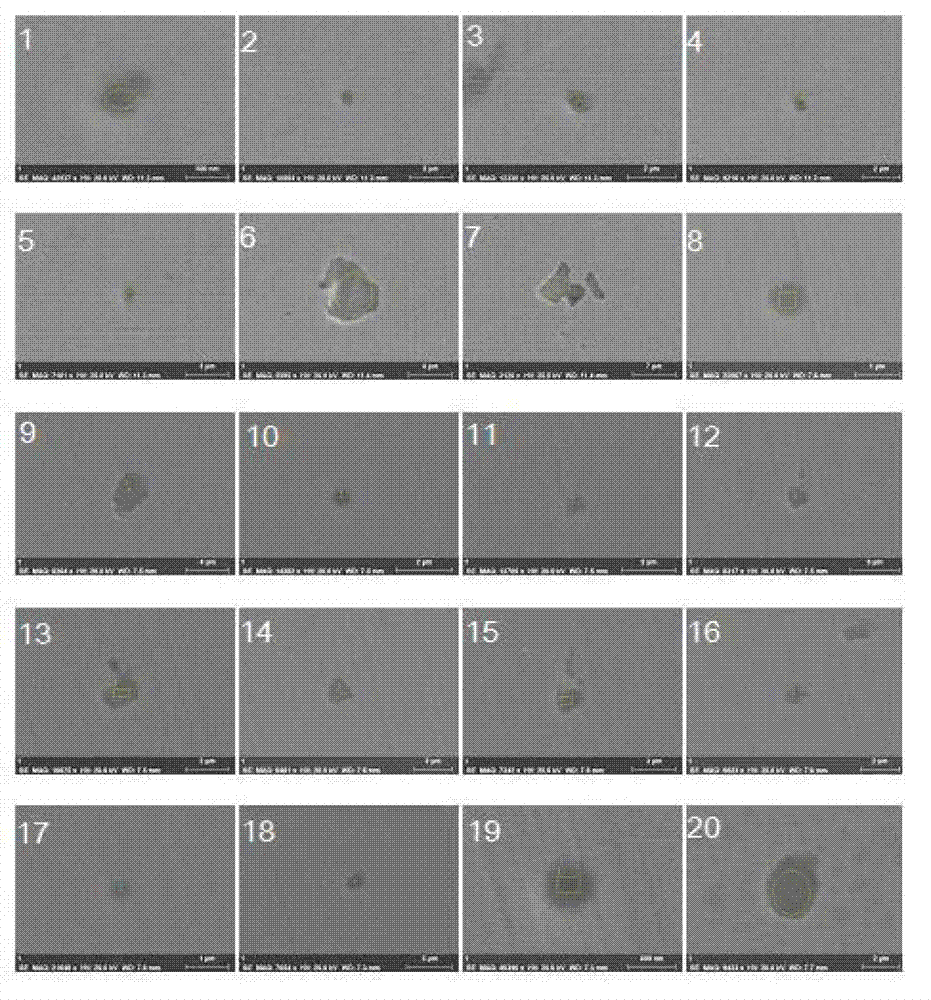

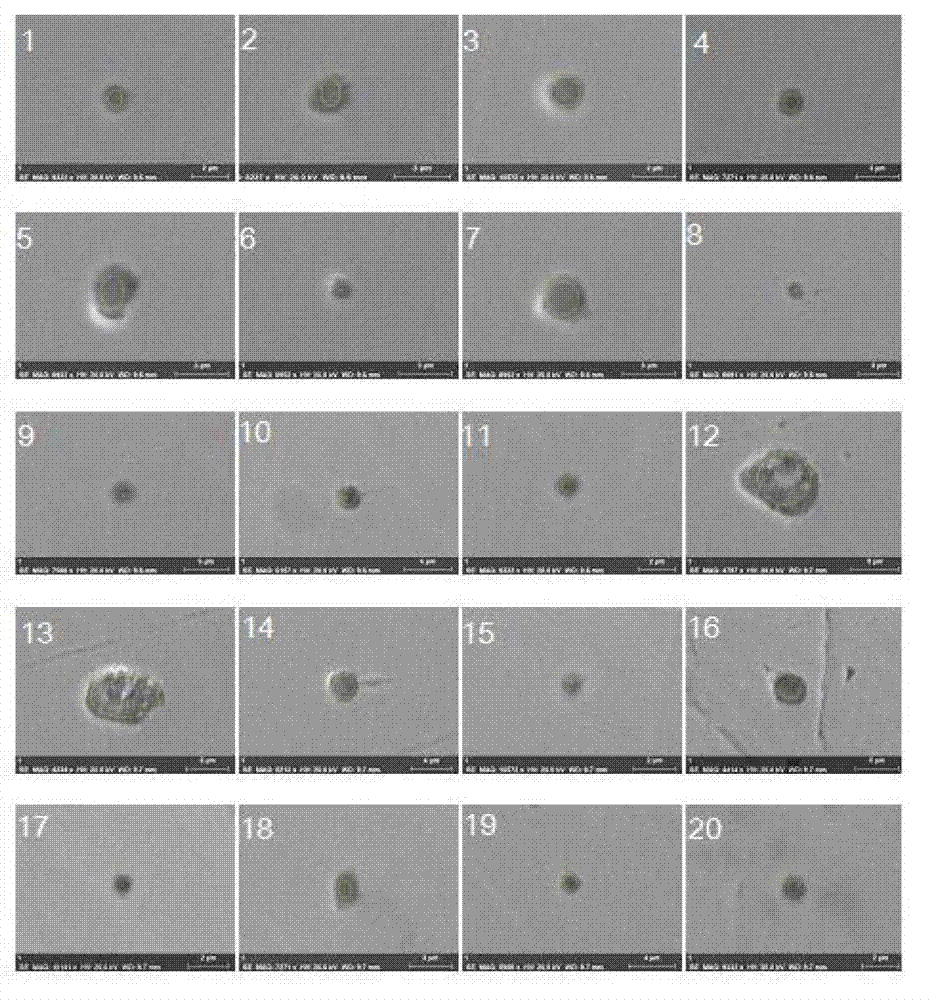

technical field [0001] The invention belongs to the technical field of steelmaking, in particular to a high-alkalinity synthetic slag for refining outside a furnace, and is especially suitable for desulfurization of pipeline steel molten steel and controlled removal of inclusions. Background technique [0002] With the development and utilization of my country's oil and natural gas resources, low-alloy, high-strength, high-toughness high-grade pipeline steel will become a class of steel that is in great demand in the national economy in this century. Oil pipeline steels are mostly used in remote areas with harsh environments and under corrosive conditions, which require high quality. Pipeline steels are required to have high strength, high toughness, good weldability, good resistance to hydrogen-induced cracking (HIC) and H 2 S Corrosion (SCC) Capability. Both HIC and SCC of pipeline steel are closely related to sulfur and inclusions in steel. For pipeline steel, reducing t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C7/076

CPCY02P10/20

Inventor 孙彦辉方忠强熊辉辉罗磊

Owner UNIV OF SCI & TECH BEIJING

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com