Non-nail connection combined fire-proof exhaust duct and producing method thereof

A technology for air exhaust ducts and toothing, which is applied to vertical pipes, building components, buildings, etc., can solve the problems of easy-to-corrosion flue, falling apart, and easy to be corroded, so as to overcome corrosion fracture and achieve high mechanical strength , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

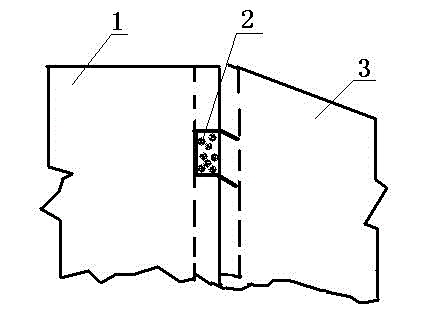

[0046] Embodiment 1. make the plank raw material composition and process steps of the fire-proof box flue exhaust duct according to the content of the invention to produce qualified plate products to make the fire-proof box flue exhaust duct, and the geometric dimensions require as follows:

[0047] Length x width x height 450 x 300 x 3000mm

[0048] Take the standard fireproof board 3000*1220*15mm, and saw the board into two pieces that need to be connected according to the geometric dimensions of the fireproof box flue, and then choose the combination method of angular tooth connection, and saw the joint parts into angular tooth shape, so that the combined The flue exhaust duct of the fireproof box can meet the required geometric dimensions of length × width × height (450 × 300 × 3000 mm). In order to prolong the service life, be safe, reliable, environmentally friendly and energy-saving, when the temperature at the production site is high, the use of magnesite adhesives sho...

Embodiment 2

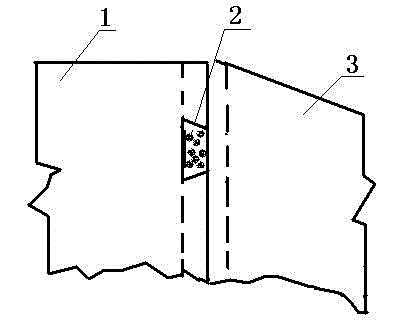

[0049] Embodiment 2. According to the content of the invention, the plate raw material composition and process steps of making the fireproof box flue exhaust duct produce qualified plate products to make the fireproof box flue exhaust duct, and the geometric dimensions are as follows:

[0050] Length x width x height 600 x 450 x 3000 mm

[0051] Take two pieces of standard fireproof boards (3000×1220×15 mm), and saw the boards into two pieces of Type A (600mm) and Type B (450mm) according to the geometrical dimensions of the fireproof box flue, and then choose according to the straight tooth shape and The combination method of angular tooth shape mixed connection, sawing the joint parts into a mixed tooth shape, so that the combined fireproof box flue can meet the required geometric dimensions of length x width x height (600 x 450 x 3000mm). In order to prolong the service life, be safe, reliable, environmentally friendly and energy-saving, when the temperature at the producti...

Embodiment 3

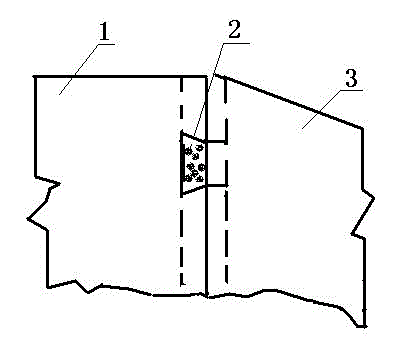

[0052] Embodiment 3. According to the content of the invention, make the raw material components and process steps of the fire-proof box flue exhaust plate to produce qualified plate products to make the fire-proof box flue exhaust, and the geometric dimensions require as follows:

[0053] Length x width x height 300 x 250 x 2000 mm

[0054] Take one piece of standard fireproof board (3000×1220×15 mm), saw the board into two pieces of Type A (300mm) and Type B (250mm) according to the geometrical requirements of the fireproof flue, and then choose the combination method of straight teeth, Saw the connecting parts into a straight-tooth shape, so that the combined exhaust duct can meet the required geometric dimensions of length x width x height (300 x 250 x 3000mm). In order to prolong the service life, be safe, reliable, environmentally friendly and energy-saving, when the temperature at the production site is low, the use of magnesite adhesives should include the following ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com