Energy saving system of electrically driven feed pump of power frequency-variable frequency switching type liquid coupling

A technology of hydraulic coupling and electric feed water pump, which is applied in the direction of non-variable pumps, machines/engines, pumps, etc., and can solve the problems of abnormal rise in working oil temperature, large loss of hydraulic coupling, and low operating speed, etc. problems, to achieve the effect of simple structure, reduced power supply coal consumption, and high overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

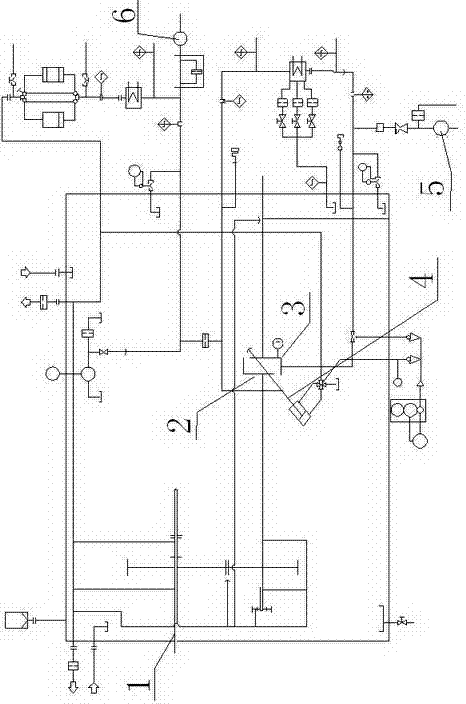

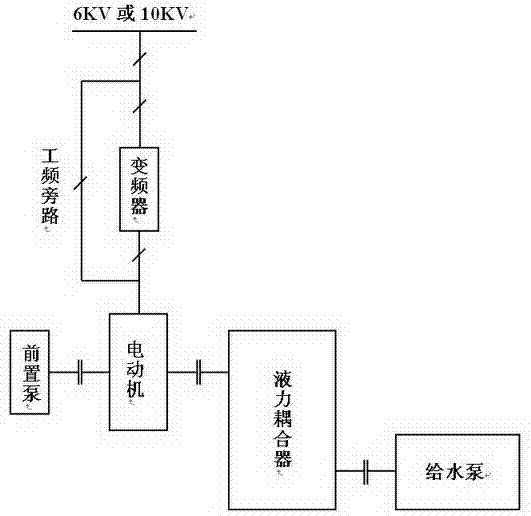

[0010] In the present invention, a frequency converter and its industrial frequency bypass are installed between the power circuit breaker and the motor, and the industrial frequency conversion power supply is input to the motor through switching. One end of the motor coaxially drives the front pump, and the other end coaxially drives the hydraulic coupling input. shaft, the output shaft of the hydraulic coupling drives the water pump, and the lubricating oil pump and working oil pump are designed and installed in the lubricating oil system and working oil system of the hydraulic coupling, so that the same hydraulic coupling has two operation modes, the first operation The mode is a speed-regulating hydraulic coupling with volumetric speed regulation when the power frequency is input at a fixed speed. The second operation mode is a speed-up gearbox with a speed-regulation pump wheel when the frequency conversion speed regulation input is used. The two operation modes are switche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com