Vent valve assembly for car retarder

A ventilation valve and reducer technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of vehicle reducer damage, easy aging, short service life, etc., to reduce the contact area and use Good stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

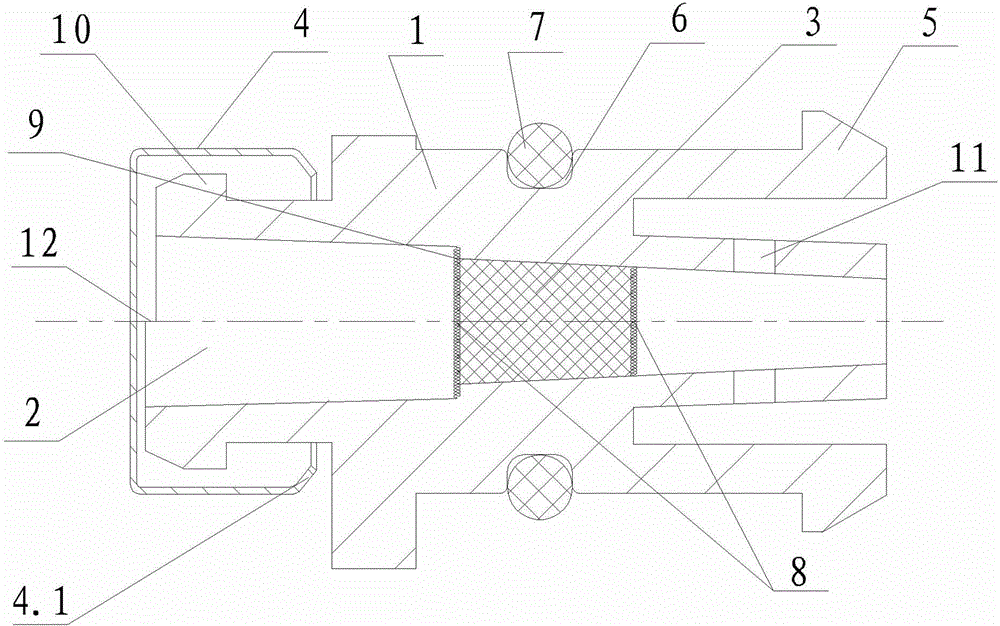

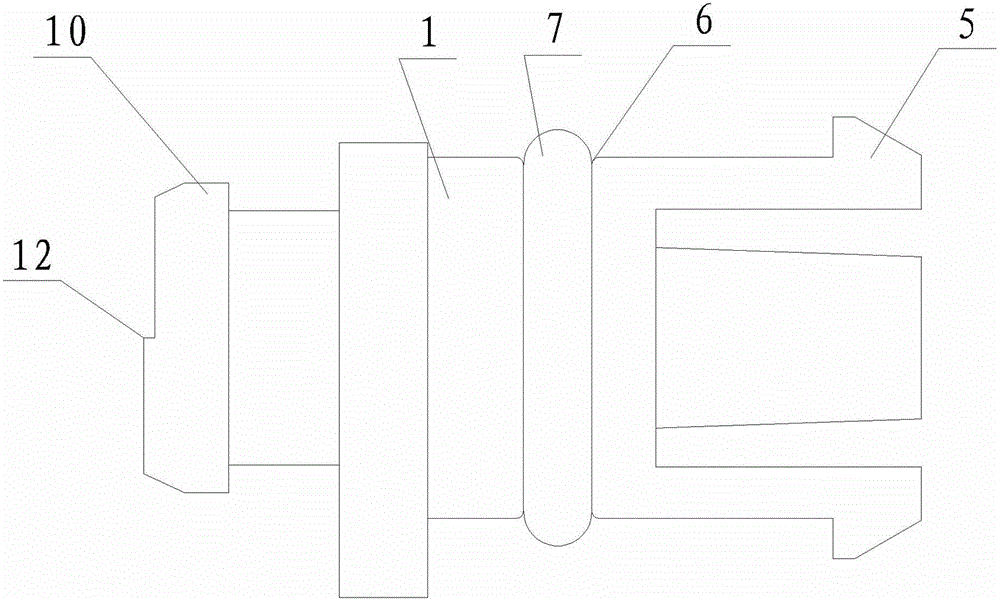

[0018] like figure 1 and figure 2 A vehicle reducer breather valve assembly is shown, which includes a breather valve body 1 made of plastic and a central hole 2 on the breather valve body 1. Generally, the breather valve body 1 is injection molded from engineering plastics. The center hole The aperture at one end of 2 is smaller than the aperture at the other end of the center hole 2. It can also be understood that the center hole 2 is a hole with a frustum-shaped structure. Lipophilic solid substances such as paper, the cost of these commercially available lipophilic solid substances is relatively low, which can reduce the cost of use. One end of the vent valve body 1 central hole 2 with a large aperture is provided with a dustproof cap 4, and the center The small end of the hole 2 is assembled in the vehicle reducer, and the large end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com