Backlight module and display device

A technology for backlight modules and display devices, applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problem of optical film colliding with the display panel, the display panel detaching from the carrying frame, and weakening the fixing effect of the display panel and the carrying frame and other issues to achieve the effect of ensuring display quality, good display quality, and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

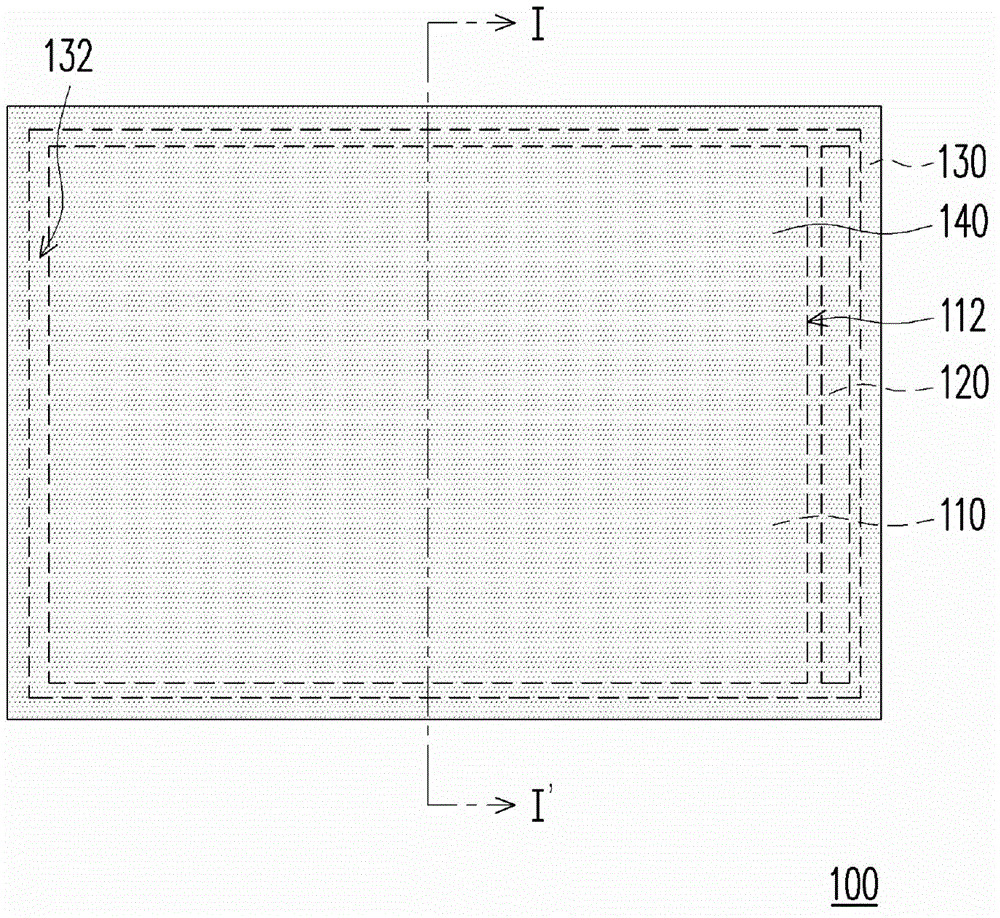

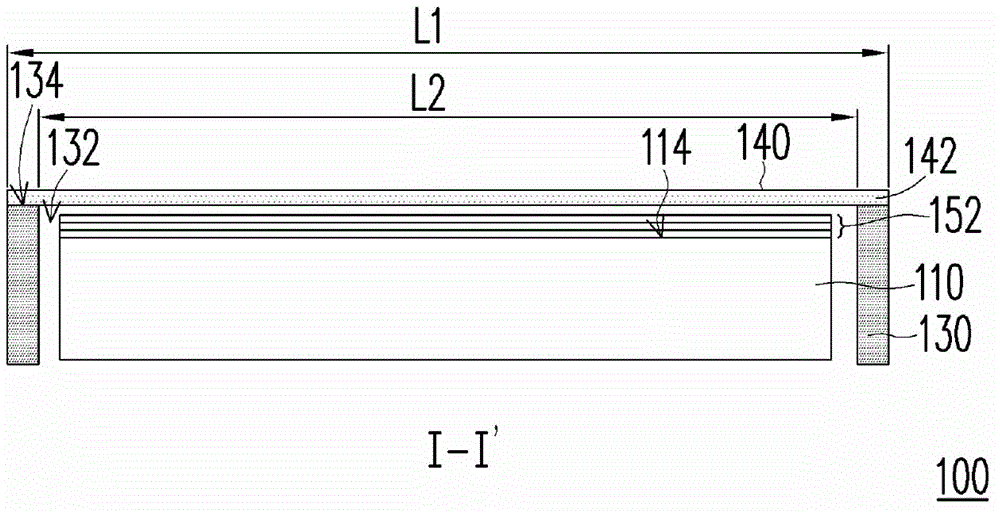

[0035] Figure 1A It is a top view of a backlight module according to an embodiment of the present invention. Figure 1B for Figure 1A The cross-sectional view of the backlight module along the line I-I'. Such as Figure 1A and 1B As shown, the backlight module 100 includes a light guide plate 110 , a light emitting element 120 , a supporting frame 130 and a transparent film 140 . The light guide plate 110 has a light incident surface 112 and a light exit surface 114 , and the light emitting element 120 is disposed beside the light incident surface 112 . Here, the light emitting element 120 is, for example, a light emitting diode (LED light bar), a cold cathode fluorescent lamp (CCFL) or other suitable light emitting elements, for emitting light, entering the light guide plate 110 through the light incident surface 112 , and passing through The light emitting surface 114 emits out of the light guide plate 110 . The carrying frame 130 surrounds the light guide plate 110 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com