Device for measuring oblique projection of glass mold die cavity bottom groove

A technology of glass molds and bottom grooves, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems such as successful applications in the industry that have not been heard of, and technical inspirations that have not been seen, so as to meet the detection speed requirements and reduce operations. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

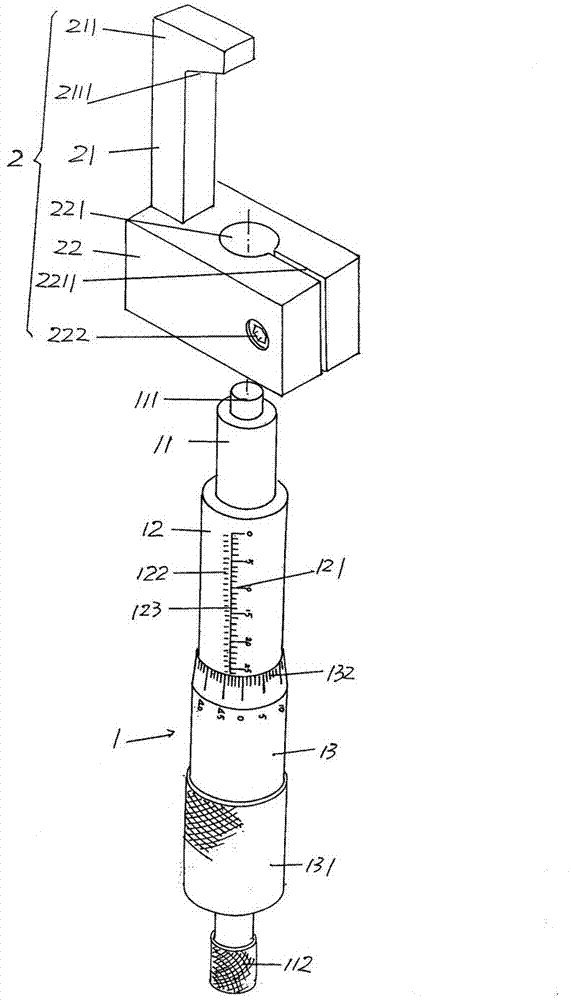

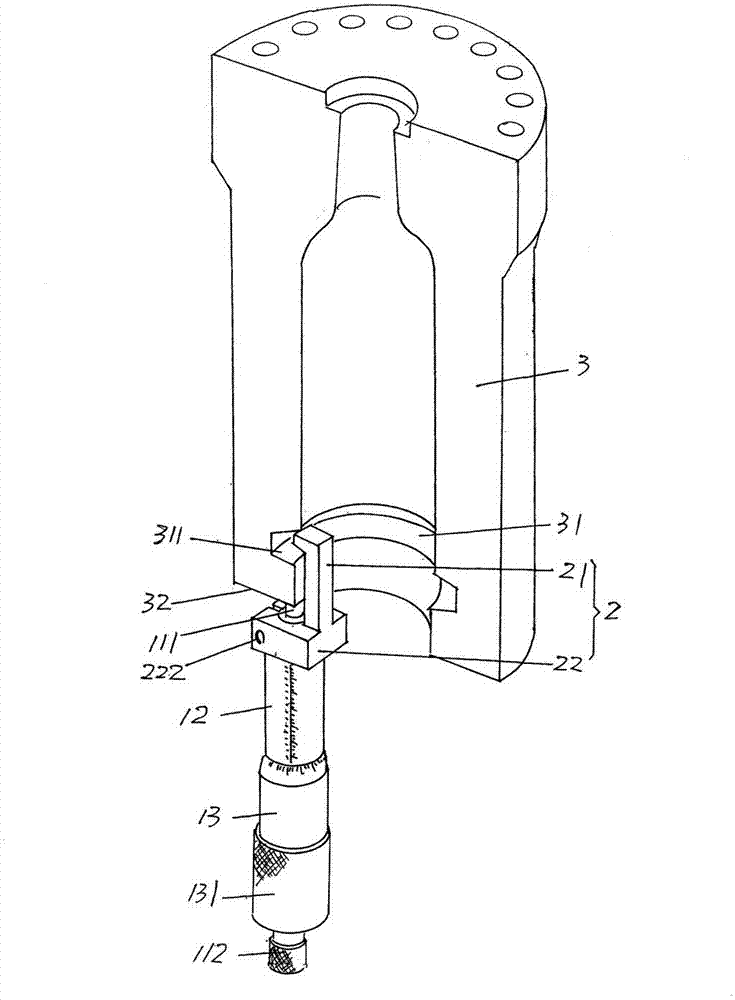

[0011] See figure 1 , provides a known micrometer 1 composed of a micrometer screw 11, a fixed sleeve 12 matched with the micrometer screw 11, and a micrometer cylinder 13 matched with the fixed sleeve 12 and having a micrometer cylinder knob 131, The micrometer 1 of this kind of structure can be purchased from commercially available channels, for example, preferably but not limited to, the model SHJX-2A-micrometer produced by China Shanghai Jinxin Measuring Tools and Cutting Tools Co., Ltd. and sold before the application is proposed . There are scale marks 121 at intervals of 1 mm on the aforementioned fixed sleeve 12 , and there are second scale marks 122 at intervals of 0.5 mm at positions corresponding to adjacent first scale marks 121 . at present figure 1 The position state shown is an example, the first scale marking line 121 is located on the right side of the height direction of the fixed sleeve 12, while the second scale marking line 122 is located on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com