Assembled paying-off pulley and paying-off tackle

A pay-off pulley, assembled technology, applied in the installation of cables, overhead lines/cable equipment, electrical components, etc., can solve the problems of high transportation costs, difficult removal, and heavy workload, saving engineering costs, reducing Manufacturing cost and the effect of improving ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

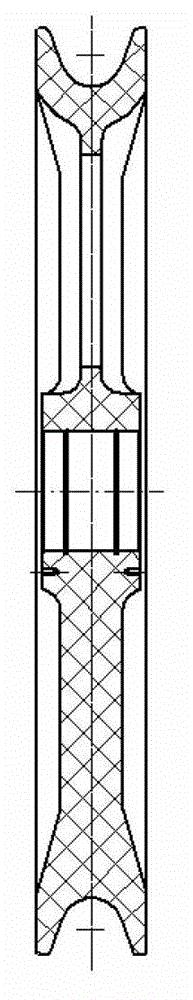

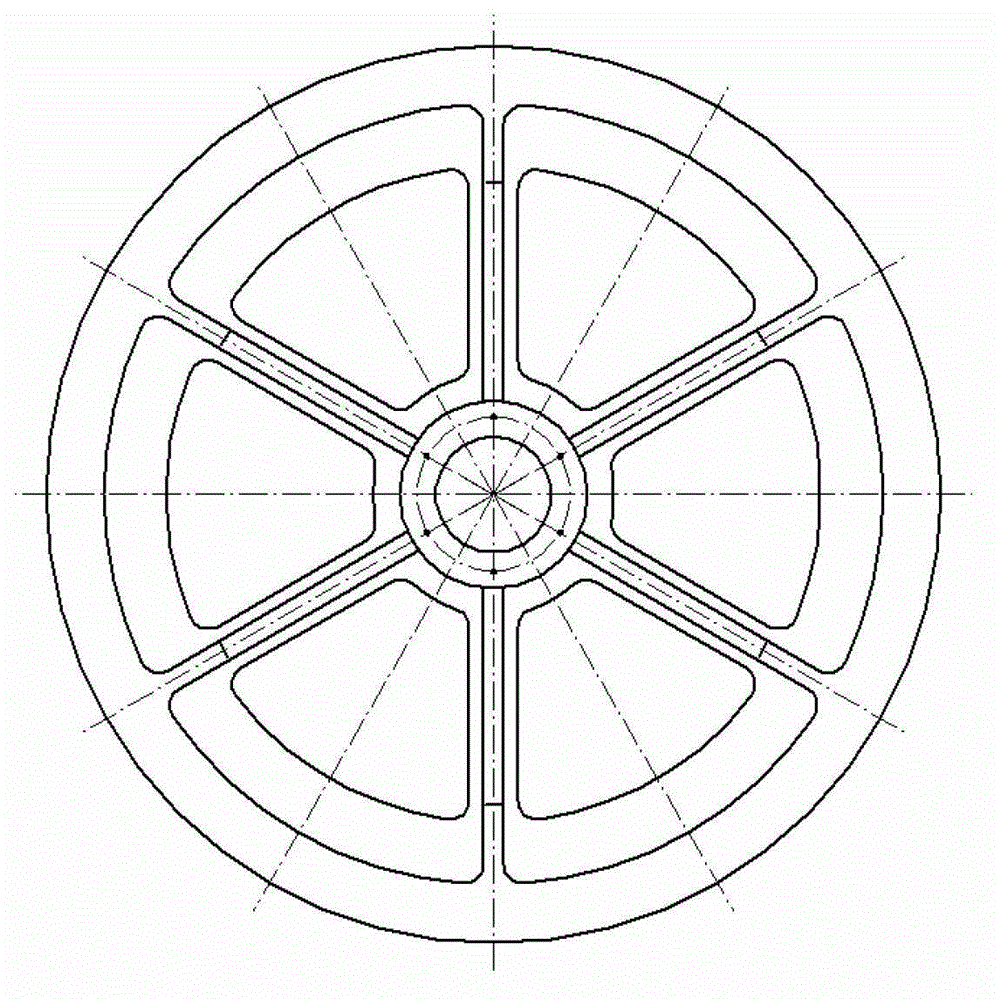

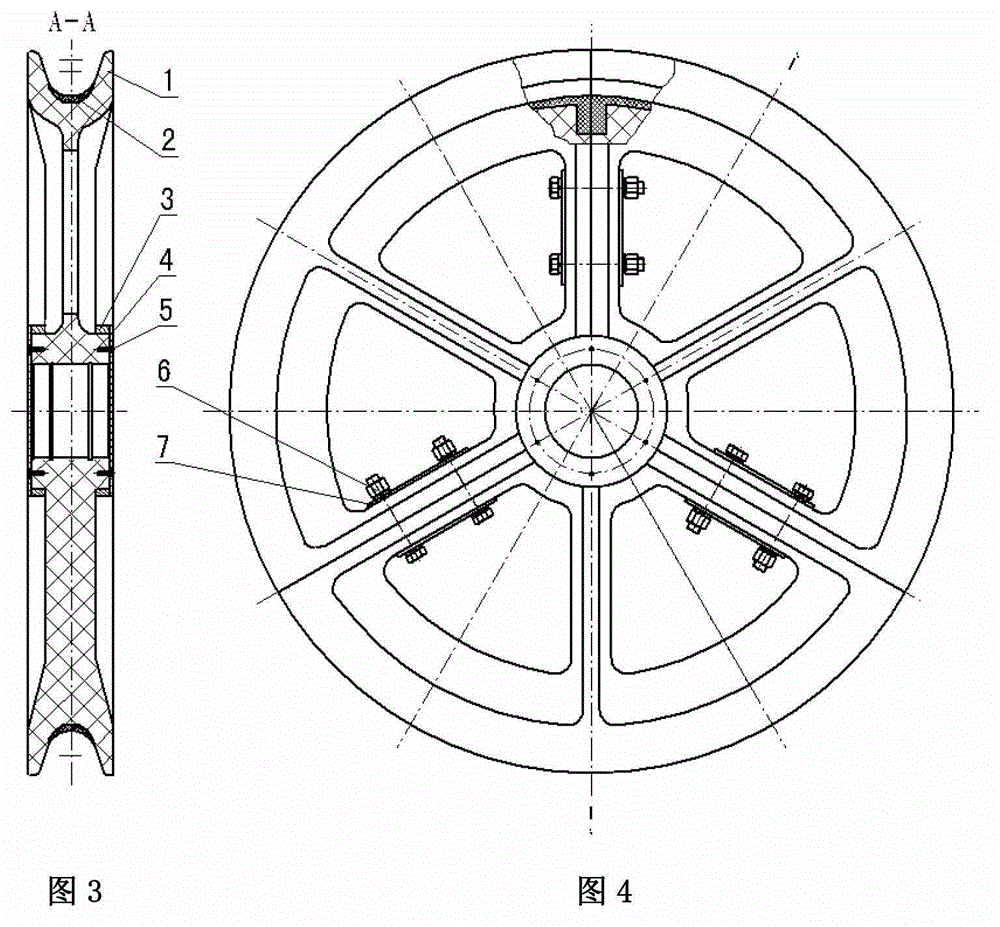

[0033] Such as image 3 , Figure 4 and Figure 6 In the shown embodiment, the pay-off pulley provided by the present invention is mainly composed of three identical pulley blocks 1 through threaded connection, and the rubber lining 2 is sleeved on the pulley body formed by the threaded connection of the pulley blocks 1, and The rubber lining 2 is in interference fit with the pulley body, and the fit tolerance is less than -1mm. The pulley block 1 is a fan-shaped frame, and the central angle of each pulley block 1 is the same as 120°, and three pulley blocks 1 are assembled into a 360° pulley body; the pulley body can also be composed of 2 pulley blocks with a central angle of 180° It consists of 1 or 4 pulley blocks 1 with a central angle of 90°. The joint surface between the pulley blocks 1 is smooth, and the diameter concentrici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com