Five-degree of freedom green fence pruning machine

A technology of trimming machine and degree of freedom, which is applied to the equipment for trimming hedges and other directions, can solve the problems that the control system is difficult to implement, the scope of application is narrow, and the function is single, and the effect of improving the efficiency of trimming and modeling, reducing the labor intensity, and having a simple and compact structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

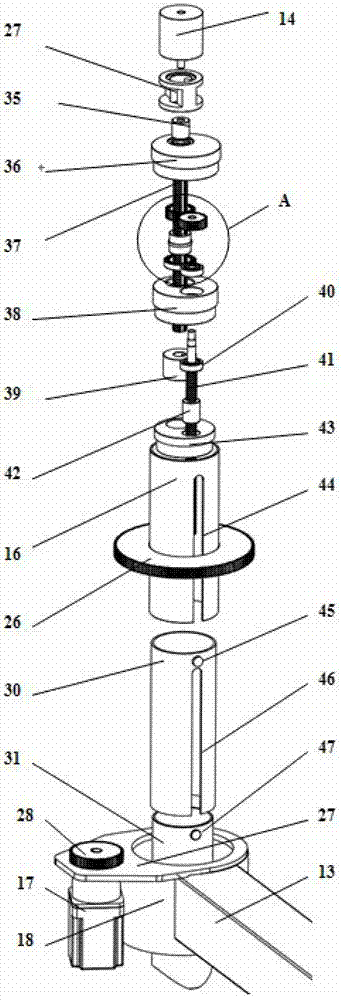

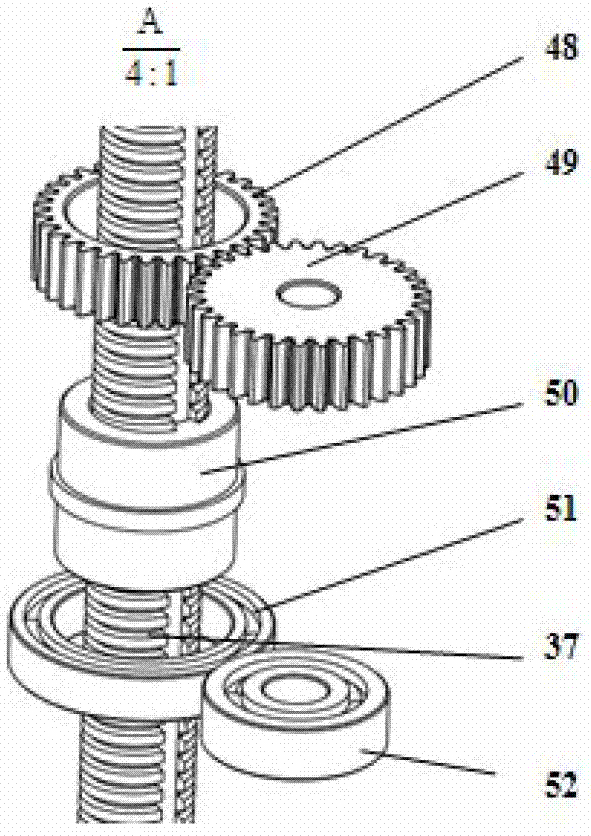

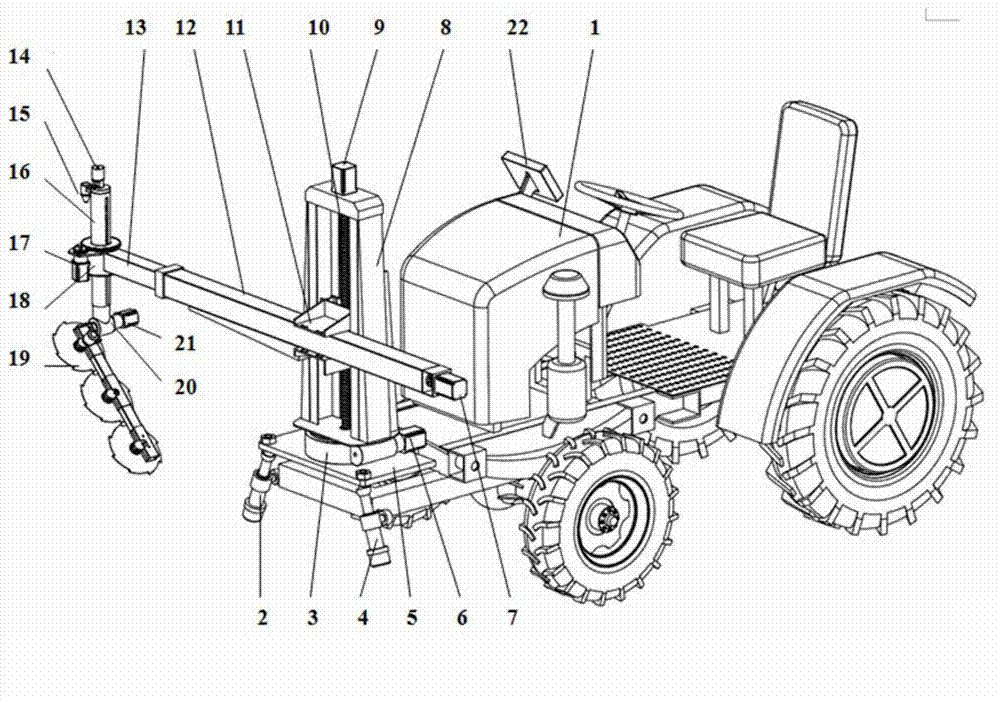

[0040] figure 1 It is a structural schematic diagram of the five-degree-of-freedom hedge seedling pruning machine of the present invention, including a hand posture adjustment platform installed in front of the carrying vehicle 1, a rotating base 3 capable of 360° rotation is installed on the pruning manipulator posture adjustment platform, and the lifting mechanism is fixedly installed on the On the rotating base 3, the telescopic mechanism is fixedly installed on the elevating frame 11 of the elevating mechanism and can rise or fall together with the elevating frame 11. At the front end of the mechanism, the vertical take-off and landing mechanism is installed on the trimming cutter head rotating device, and the trimming cutter head inclination adjustment joint 20 is fixed on the lower end of the vertical take-off and landing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com