Scraped glass smashing device

A crushing device, crushing device technology, applied in the direction of grain processing, etc., can solve the problems of low efficiency, easy to cut operators, etc., and achieve the effects of improved safety, convenient handling and subsequent processing, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

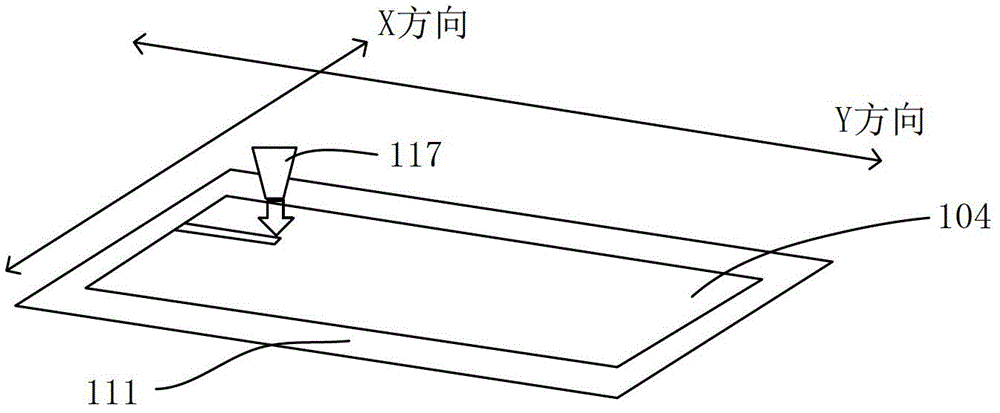

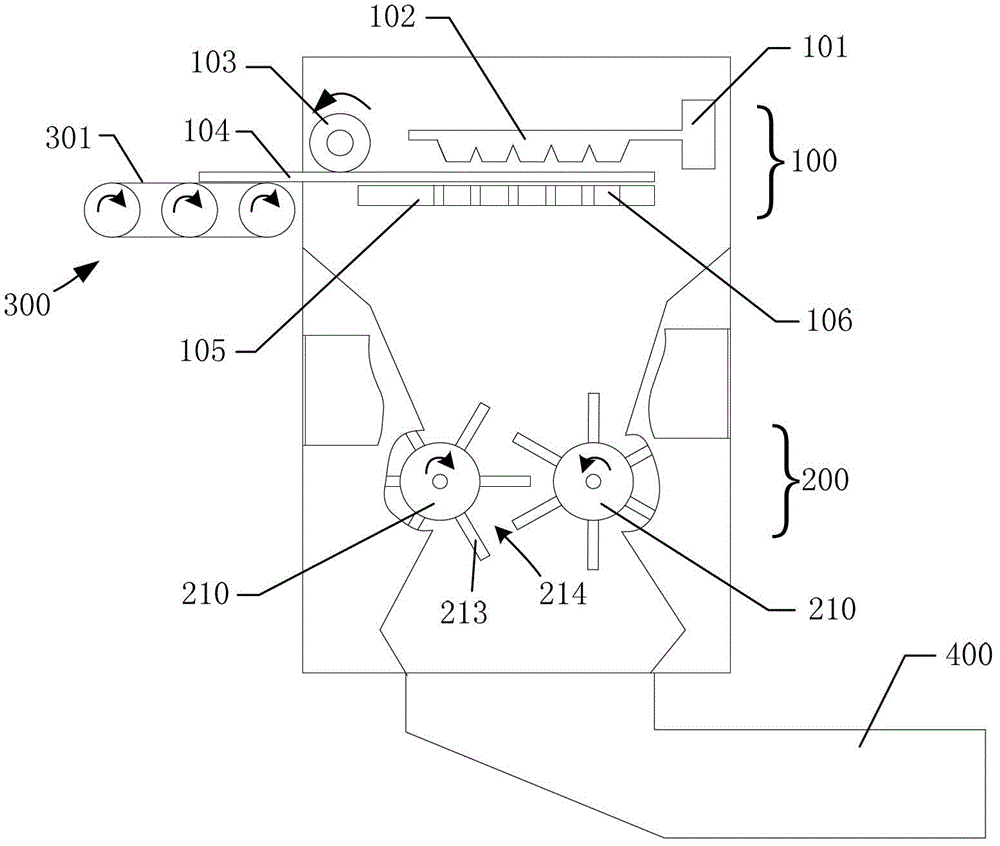

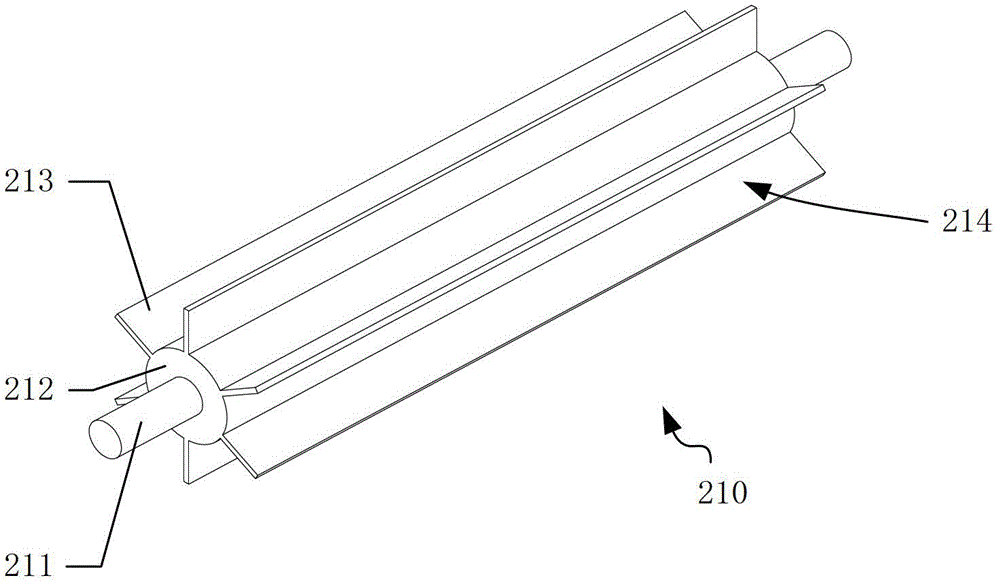

[0023] Such as figure 2 Shown is the waste glass crushing device of the present invention, which includes a vibration crushing device 100, the vibration crushing device 100 includes: a vibrating hammer 102 directly acting on the glass substrate, used to drive the vibrating hammer 102 to vibrate up and down to generate vibration container 101, and a crushing platform 105 for carrying scrap glass 104. The vibrating hammer 102 of the vibration breaking device 100 vibrates up and down to break the glass substrate 104, so that the scrapped glass substrate with a large size can be quickly decomposed into small pieces of broken glass debris, which is more convenient for handling and subsequent processing; in addition, Since the vibrating hammer 102 of the vibrating breaking device 100 can cause multiple cracks in the glass substrate 104 to be quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com