Horizontal type punching method and horizontal-type punching tool for datum holes of blade die forged blank

A technology of reference holes and blanks, applied in the field of equipment manufacturing, can solve the problems of uneven accuracy of reference holes, difficult to guarantee machining accuracy, low production efficiency, etc., to improve machining accuracy, reliable machining methods, and improve the effect of difficult punching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

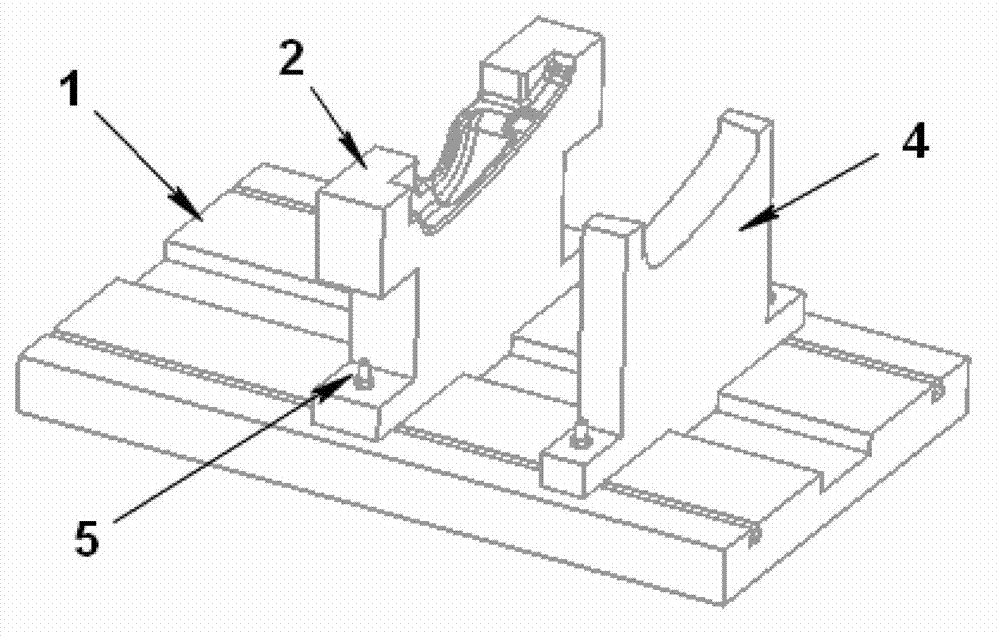

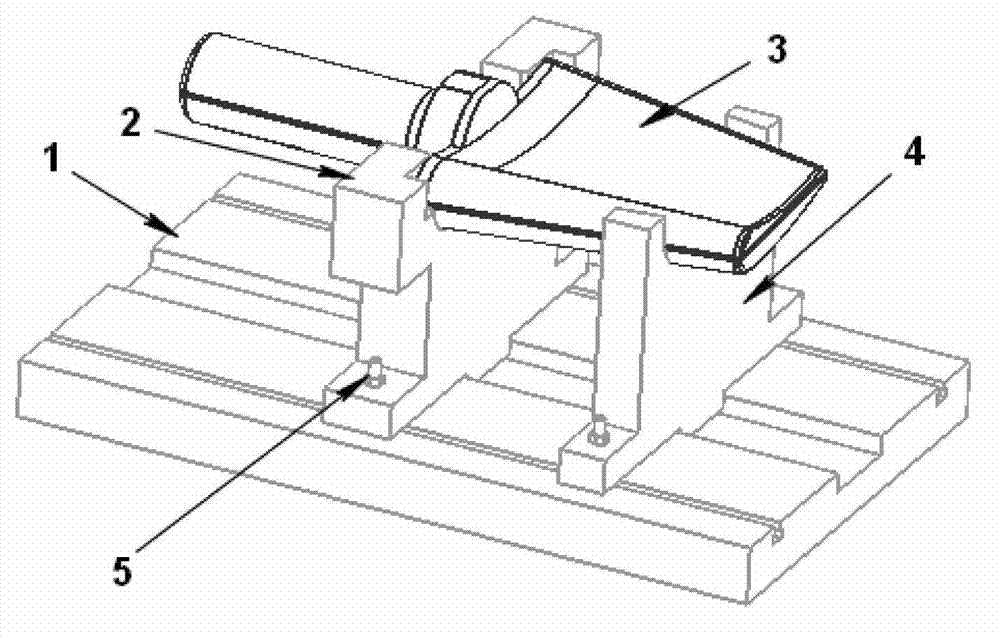

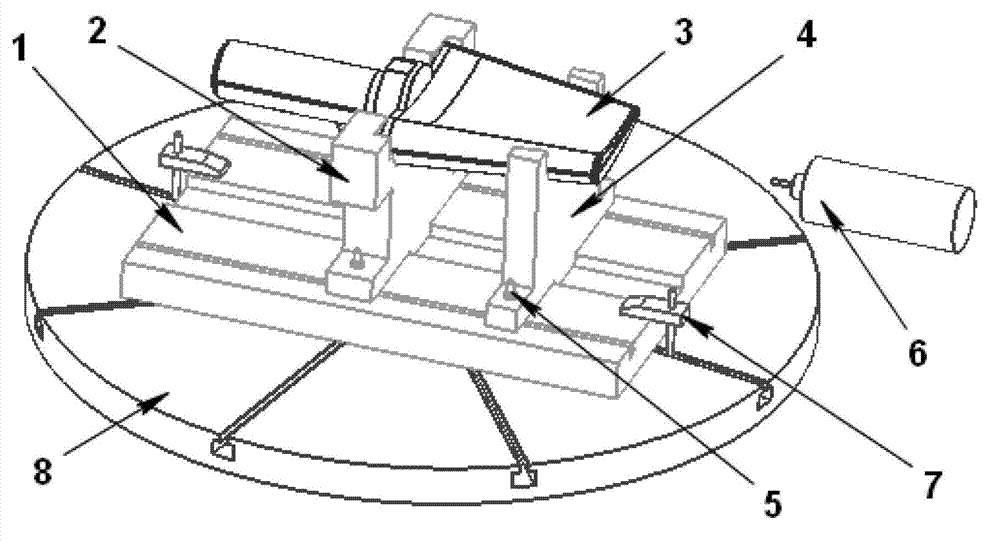

[0047] Such as Figure 1-Figure 3 As shown, in this embodiment, the horizontal punching tooling includes a bottom plate 1, a first cross-section template 2 and a second cross-section template 4, wherein the first cross-section template 2 and the second cross-section template 4 are respectively passed through T-shaped bolts and The nut 5 is vertically fixed on the bottom plate 1, and the first cross-section template 2 and the second cross-section template 4 are parallel to each other; the upper ends of the first cross-section template 2 and the second cross-section template 4 are provided with grooves, The groove matches the shape of the root of the blade forging blank 3, and the second section template 4 matches the blade end shape of the blade forging blank 3; the groove specification data of the first section template 2 and the second section template 4 are taken from the blade The cross-sectional data of the corresponding part of the forging die for die forging blank formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com