An Adaptive Floating Pressurization Device for Spot Welding Machine

A pressurizing device and self-adaptive technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problem that the electrode cannot self-adaptively press the workpiece, etc., to achieve convenient loading and moving, flexible and adjustable stroke, guaranteed The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

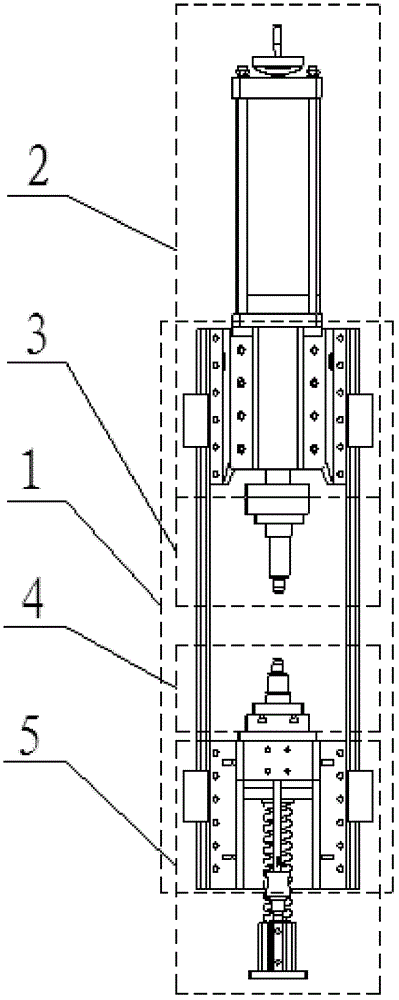

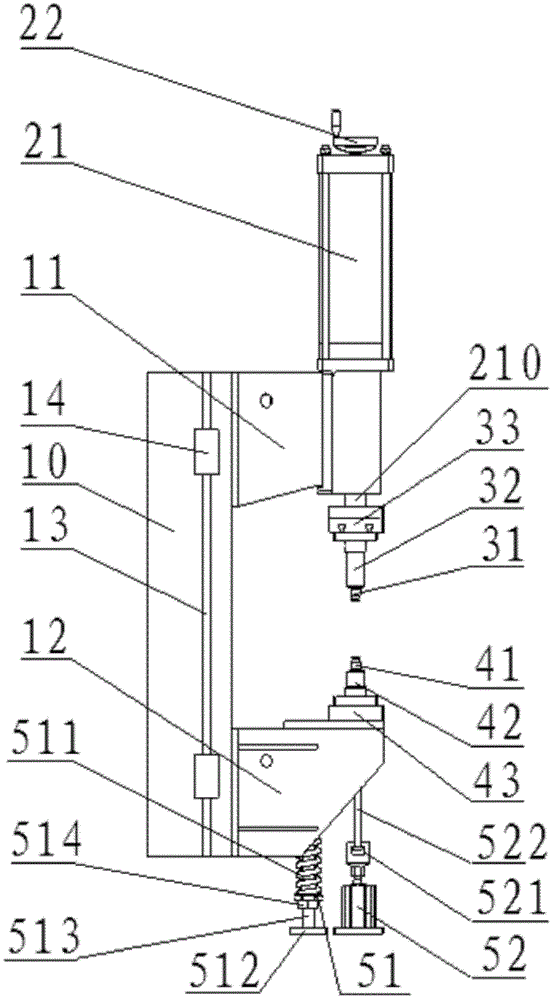

[0024] like figure 1 and figure 2 As shown, the self-adaptive floating pressurizing device used on the spot welding machine of the present invention includes a frame 1, a pressurizing mechanism 2, an upper electrode 3, a lower electrode 4, and a floating balance mechanism 5, wherein,

[0025] The frame 1, as the backbone of the adaptive floating pressurization device, bears the pressure and bending moment of the electrodes; the frame 1 includes a stand 10 and upper and lower brackets 11 and 12 connected to the upper and lower ends of the stand 10. A C-shaped structure, a vertical guide rail 13 is installed on the left and right sides of the stand 10 respectively, and the upper and lower parts of the two guide rails 13 are respectively slidably sleeved with a slider 14; the four sliders 14 are all provided with threads hole, which can be in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com