Technology of Compensating Pad for Composite Composite Mandrel

A technology of composite materials and compensation pads, which is applied in the field of combined curing technology of composite materials, can solve the problems of unqualified non-destructive testing, bonding, parts debonding, etc., and achieve the effect of complete contact, simple process method, and easy bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

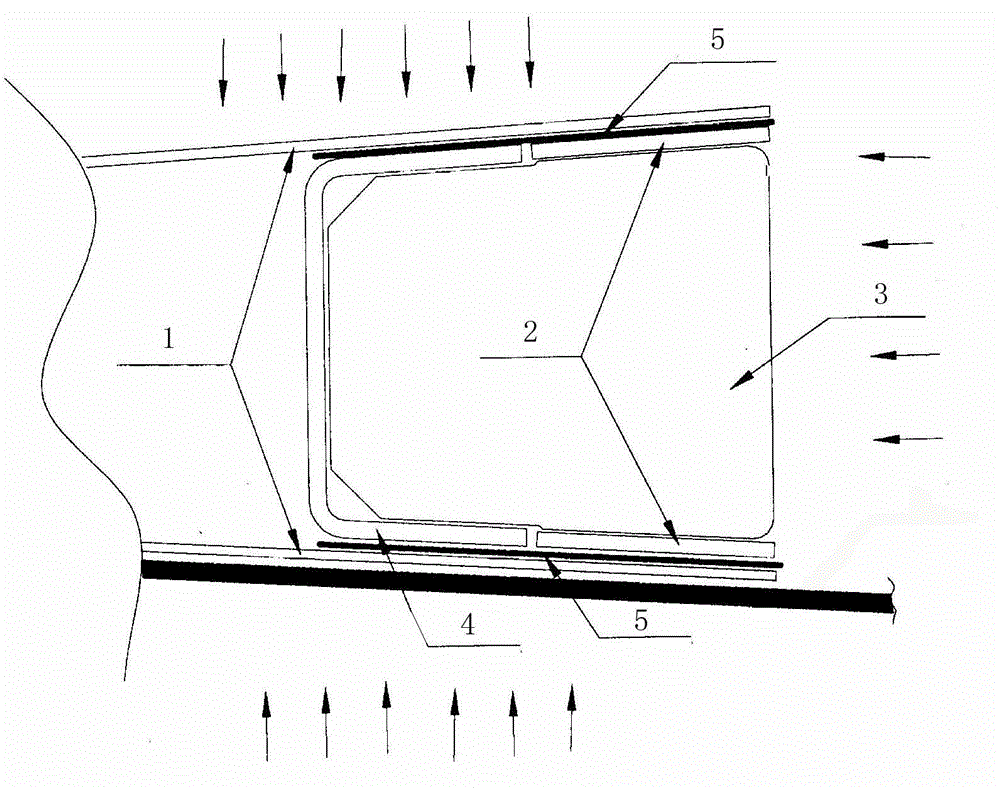

[0019] Such as figure 1 As shown, the part is composed of skin 1, pad 2 and baffle 4, and skin 1 is glued to pad 2 and baffle 4 respectively. 1. The bonding quality of pad 2 and skin 1 has a great influence on subsequent assembly.

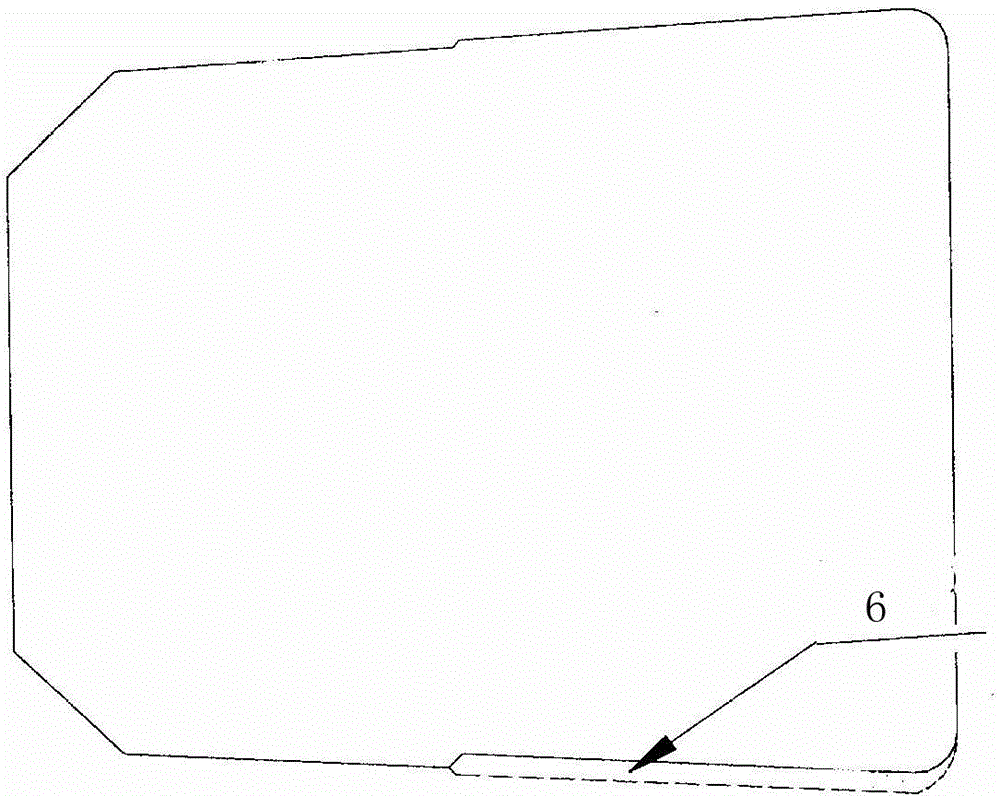

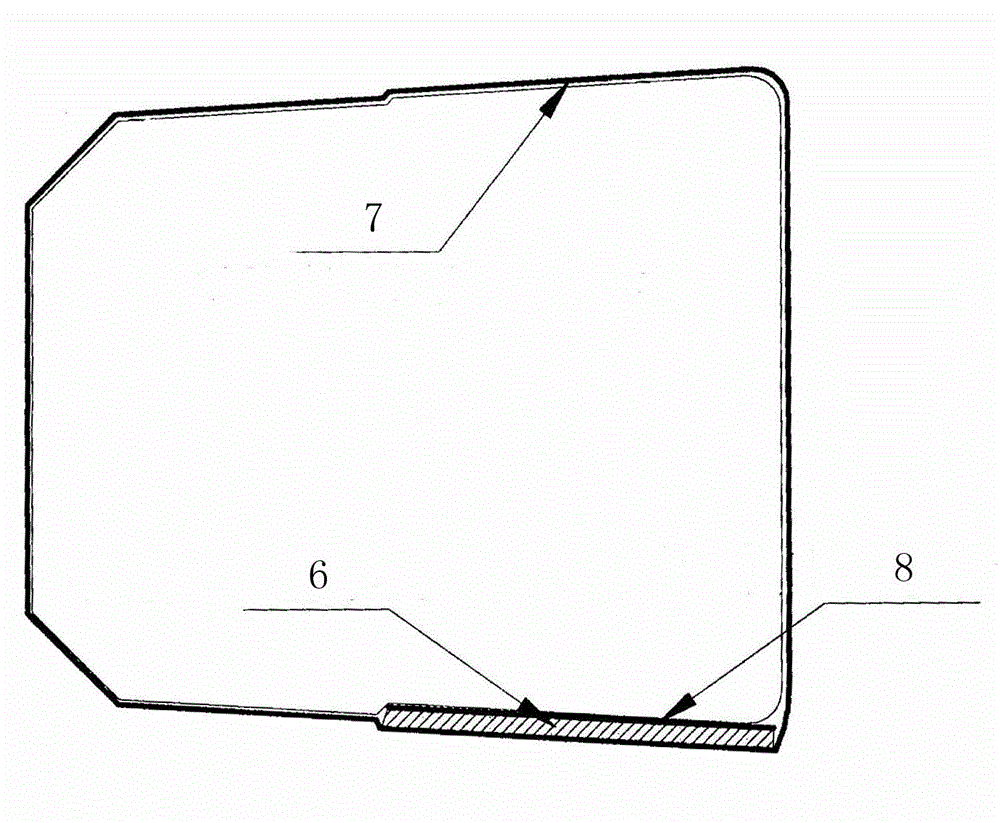

[0020] Composite mandrel compensating pad technology of the present invention still adopts combined mandrel 3 to be positioned in baffle plate 4, and the part of combined mandrel 3 protruding outside baffle plate 4 is placed on its surface pad 2, and skin 1 covers pad 2 , The composite mandrel 3 and the baffle 4 are covered inside, and the skin 1, the pad 2 and the baffle 4 are glued into one body through external curing pressure and thermal expansion. Reserve the position of the rubber compensation pad 6 on the composite core mold 3, that is, reserve the thickness of the rubber compensation pad on both sides of the composite core mold 3 by reducing the size, and then bond the rubber compensation pad 6 to the composite core mold 3 reserved positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com