Sludge drying system utilizing waste heat

A sludge drying and waste heat technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of less high-quality energy, waste of steam energy, lack of steam, etc., and achieve the effect of improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

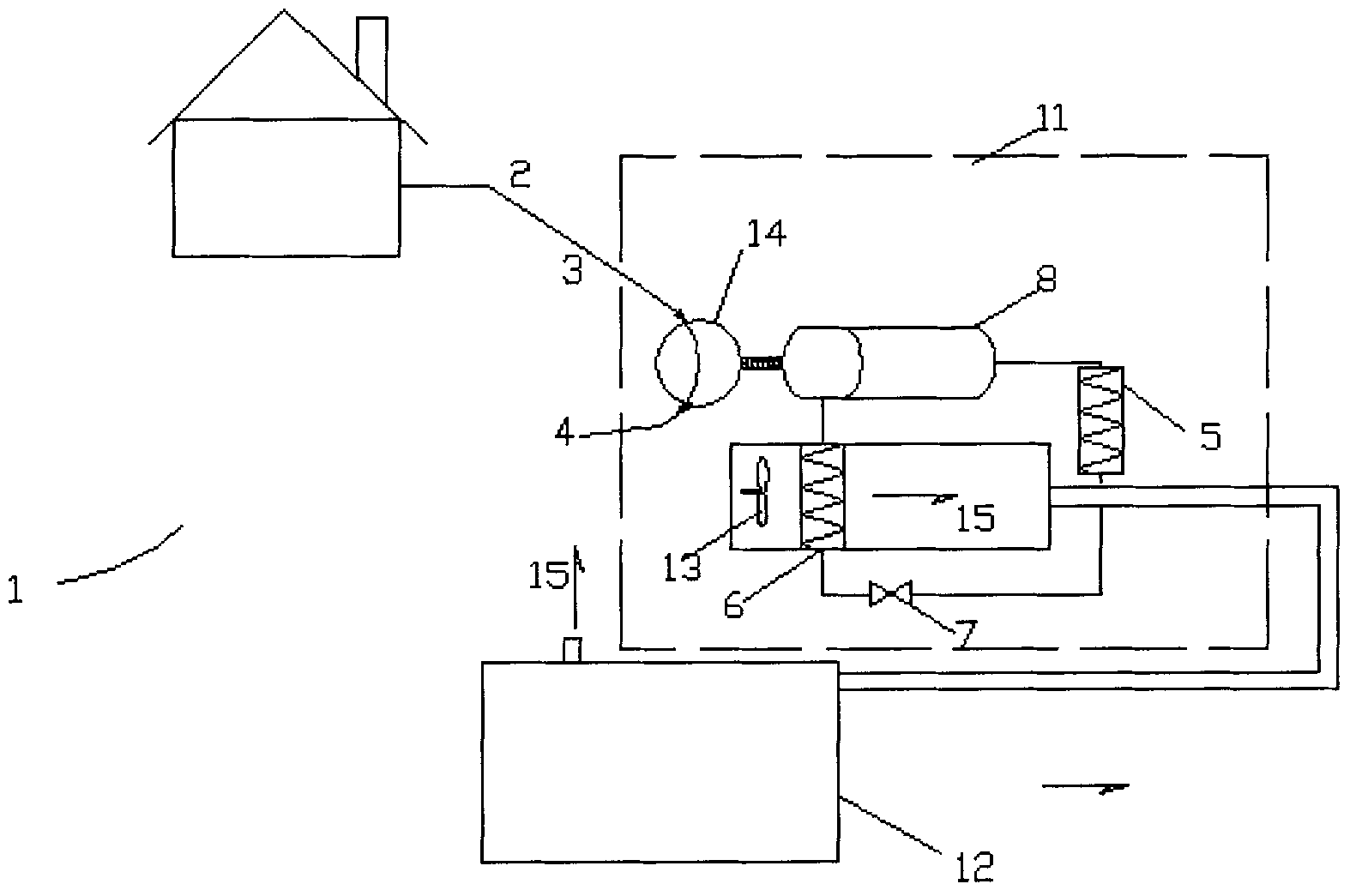

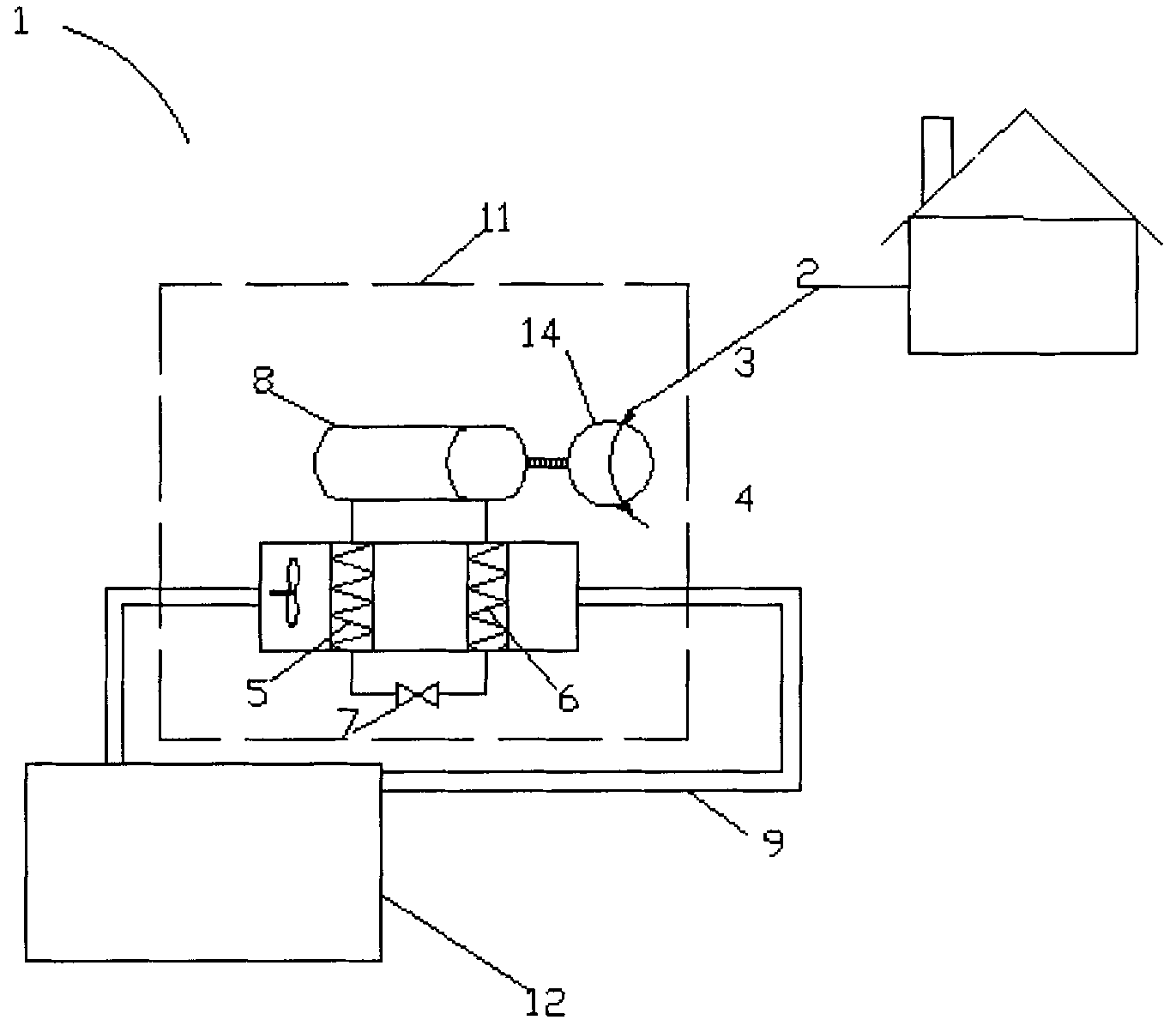

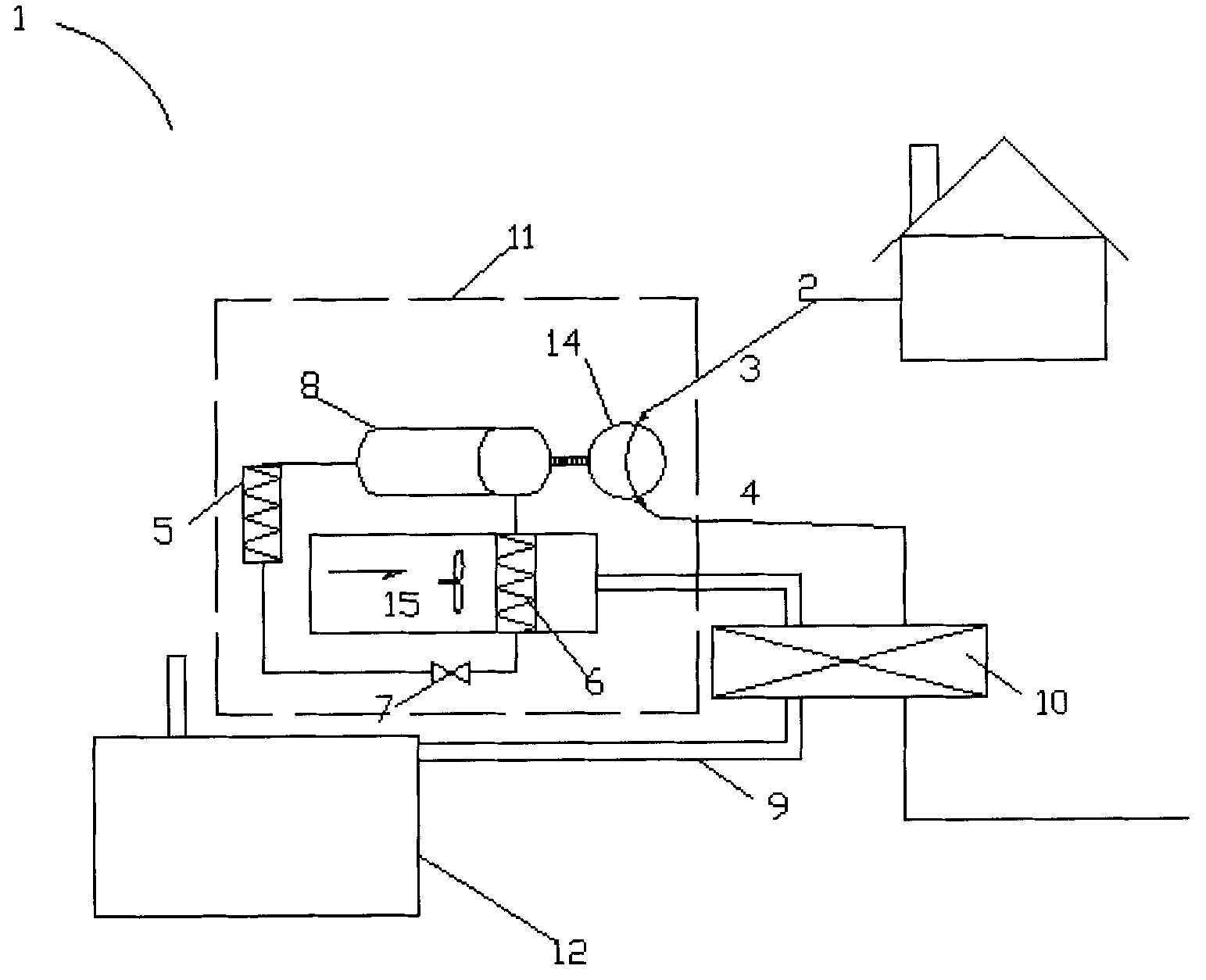

[0025] Such as figure 1 Shown is a system diagram of Embodiment 1 of the present invention, in which the whole sludge drying system 1 includes a heat pump device 11, a sludge drying device 12 and a steam supply port 2; The compressor 8 is driven to pressurize and heat the gaseous refrigerant. The refrigerant is condensed into a high-pressure liquid refrigerant through the condenser 6. It is throttled by the throttling mechanism 7 to become a low-pressure liquid. It absorbs heat and evaporates into a low-pressure liquid in the evaporator 5. The gaseous state is absorbed by the steam-driven compressor 8 and returned to the compressor, and so on. The steam supply port draws high-temperature and high-pressure steam, and the steam enters the driving part 14 of the compressor through the high-pressure steam pipeline 3 to drive the compressor 8 to rotate, and the high-pressure steam becomes exhausted steam 4 discharged from the compressor 8 after doing work. The air passage 9 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com