Asphalt pavement paving method

A technology of asphalt pavement and asphalt surface layer, which is applied in the engineering field, can solve problems such as insufficient bonding strength, achieve the effects of enhanced bonding strength, solving insufficient penetration depth, and good penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

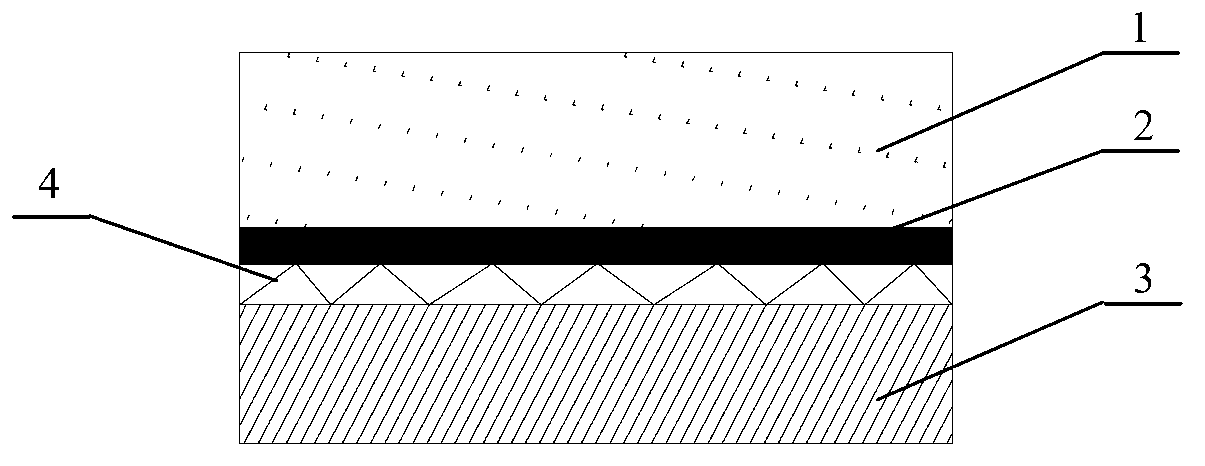

[0017] The asphalt pavement paving method of the present embodiment comprises the following steps:

[0018] (1) Transport the mixed cement-stabilized gravel mixture to the construction site, spread it evenly according to the loose paving thickness with a paver, and immediately shape the mixture after paving, when the moisture content of the mixture is greater than When the specified optimum moisture content (+1%~+2%) is reached, immediately roll the mixture until the compaction degree is greater than the specified compaction degree (95%), and immediately start health preservation for 3 days. The specific rolling the way is:

[0019] Use a heavy-duty bulldozer with a static weight of more than 25t to roll five times to make the lower part of the rolled layer dense, and use a heavy-duty three-wheel roller to continue rolling to make the upper part of the rolled layer dense and the surface smooth to form a semi-rigid base 3 .

[0020] (2) Carry out fine milling and cleaning on t...

Embodiment 2

[0030] The asphalt pavement paving method of the present embodiment comprises the following steps:

[0031] (1) Same as Example 1.

[0032] (2) Carry out fine milling and cleaning on the healthy semi-rigid base 3 to remove loose stones.

[0033] The specific fine milling method is:

[0034] 2.1) Accurately adjust the datum plane, transverse slope, and milling depth of the milling machine according to the datum point. The leveling instrument is always in normal working condition. Milling starts. The uniform speed of the milling machine is 5m / min, and the milling machine is controlled within the first 10 meters. The milling depth of the planer should be slowly adjusted from zero to the required milling depth of 4mm;

[0035] 2.2) Keep the milling depth at 4mm, and when driving at a constant speed to the last 10m, control the milling machine to slowly reduce the milling depth from 4mm to zero, and clean the surface of the semi-rigid base 3 after fine milling to remove loose sto...

Embodiment 3

[0039] The asphalt pavement paving method of the present embodiment comprises the following steps:

[0040] (2) Same as Example 1.

[0041] (2) Carry out fine milling and cleaning on the healthy semi-rigid base 3 to remove loose stones.

[0042] The specific fine milling method is:

[0043] 2.1) Accurately adjust the datum plane, transverse slope, and milling depth of the milling machine according to the datum point. The leveling instrument always maintains a normal working state. Milling starts. The uniform speed of the milling machine is 3m / min, and the milling machine is controlled within the first 10 meters. The milling depth of the planer should be slowly adjusted from zero to the required milling depth of 6mm;

[0044] 2.2) Keep the milling depth at 6mm. When driving at a constant speed to the last 10m, control the milling machine to slowly reduce the milling depth from 6mm to zero, and clean the surface of the semi-rigid base 3 after fine milling to remove loose stone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com