Tying and placing method for vertical sand barrier

A sand barrier and vertical technology, which is applied in the field of setting up vertical sand barriers, can solve the problems of restricting the large-scale implementation of sand control projects, shortage of sand control materials, and high labor costs, so as to facilitate large-scale promotion and application and reduce construction costs , Reduce the effect of wind damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

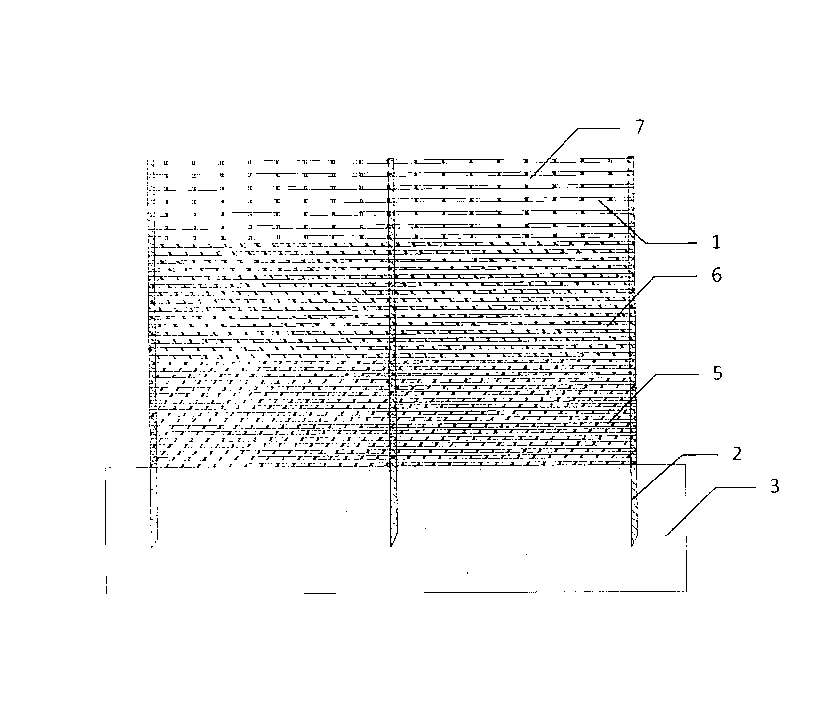

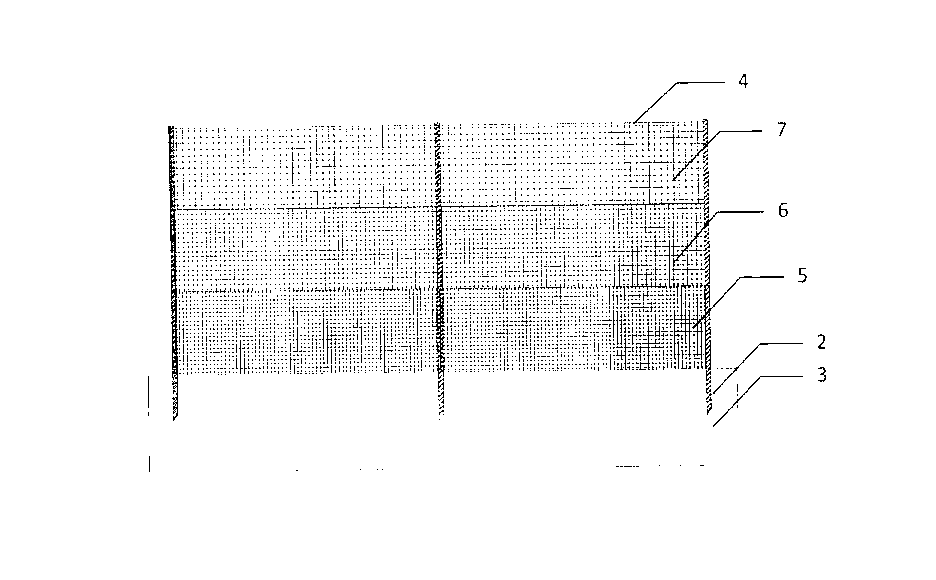

[0023] a, the production of sand barriers: bundle the plant stalks into grass handles 1 with a diameter of 1cm, and then cut the grass handles 1 into 1m sections;

[0024] b. Draw a line on the ground of the sand barrier area to be laid to determine the position of the sand barrier, and embed one end of the fixed pile 2 in the surface layer 3 on the drawn line, with an embedding depth of 30cm, and the distance between the fixed piles 2 is 1m;

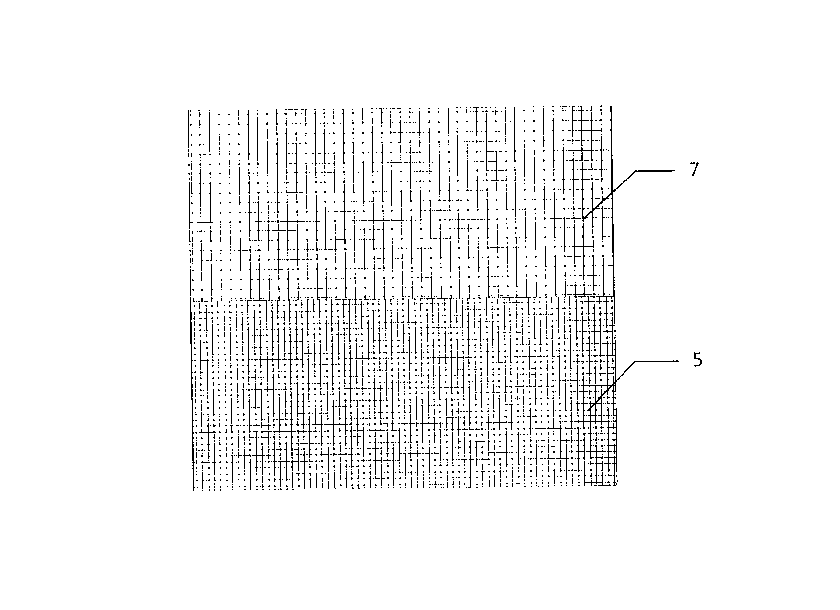

[0025] c. Place the grass bar 1 made in step a parallel to the surface between the two fixed piles, and fix the grass bar 1 on the fixed piles 2 one by one in parallel to form a sand barrier. The lower layer of the sand barrier is a tight strip 5 , the spacing is 5mm, the middle layer of the sand barrier is a dredging strip 6, the spacing is 8mm, the upper layer of the sand barrier is a ventilation strip 7, the spacing is 15mm, and the same width can be used.

Embodiment 2

[0027] a, the production of sand barriers: bundle the plant stalks into grass handles 1 with a diameter of 2cm, and then cut the grass handles 1 into 2m sections;

[0028] b. Draw a line on the surface of the sand barrier area to be arranged to determine the position of the sand barrier, and embed one end of the fixed pile 2 in the surface layer 3 on the drawn line, with an embedding depth of 35cm, and the distance between the fixed piles 2 is 1.2m;

[0029] c. Place the grass bar 1 made in step a parallel to the surface between the two fixed piles, and fix the grass bar 1 on the fixed piles 2 one by one in parallel to form a sand barrier. The lower layer of the sand barrier is a tight strip 5 , the spacing is 7mm, the middle layer of the sand barrier is a dredging strip 6 with a spacing of 12mm, the upper layer of the sand barrier is a ventilation strip 7 with a spacing of 18mm, and different widths can be used.

Embodiment 3

[0031] a, the production of sand barriers: bundle the plant stalks into grass handles 1 with a diameter of 3cm, and then cut the grass handles 1 into 1.5m sections;

[0032] b. Draw a line on the surface of the sand barrier area to be laid to determine the position of the sand barrier, and embed one end of the fixed pile 2 in the surface layer 3 on the drawn line to a depth of 40cm, and the distance between the fixed piles 2 is 1.5m;

[0033] c. Place the grass handle 1 made in step a parallel to the surface between the two fixed piles, and then fix the grass handle 1 on the fixed pile 2 one by one in parallel to form a sand barrier. The lower layer of the sand barrier is a tight strip 5. The spacing is 8mm. The middle layer of the sand barrier is a dredging strip 6 with a spacing of 15mm. The upper layer of the sand barrier is a ventilation strip 7 with a spacing of 20mm. The same width can be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com