Turntable type multi-station high-precision detection device based on multi-charge coupled device (CCD) and line laser

A detection device and turntable technology, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems affecting the detection accuracy of product height difference and dimension, affecting the detection accuracy of industrial CCD, and achieve the effect of improving detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

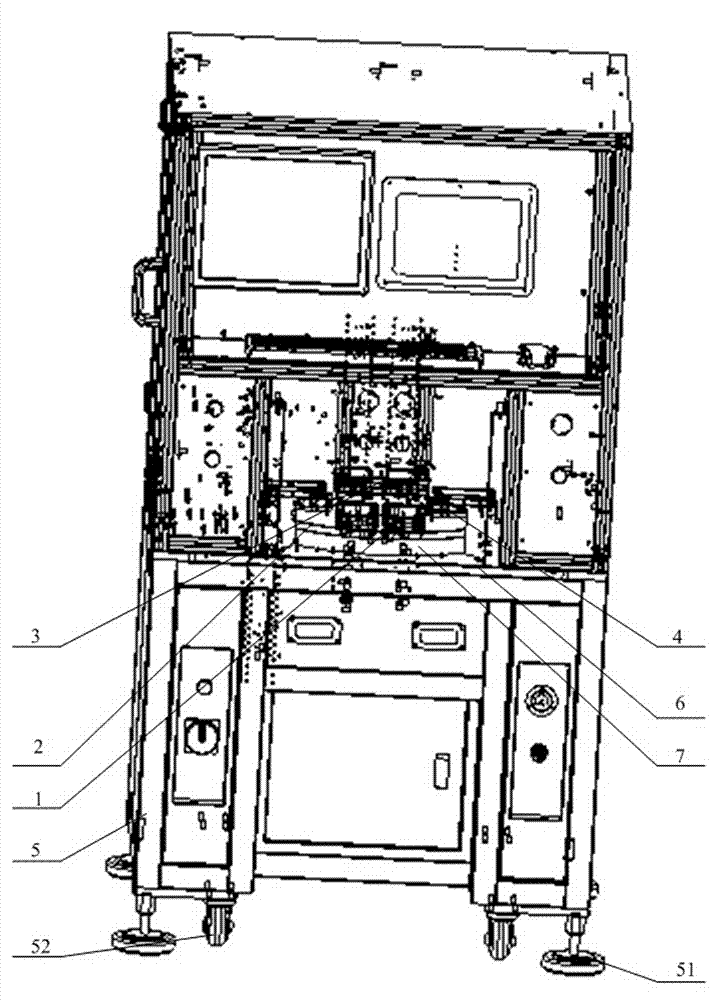

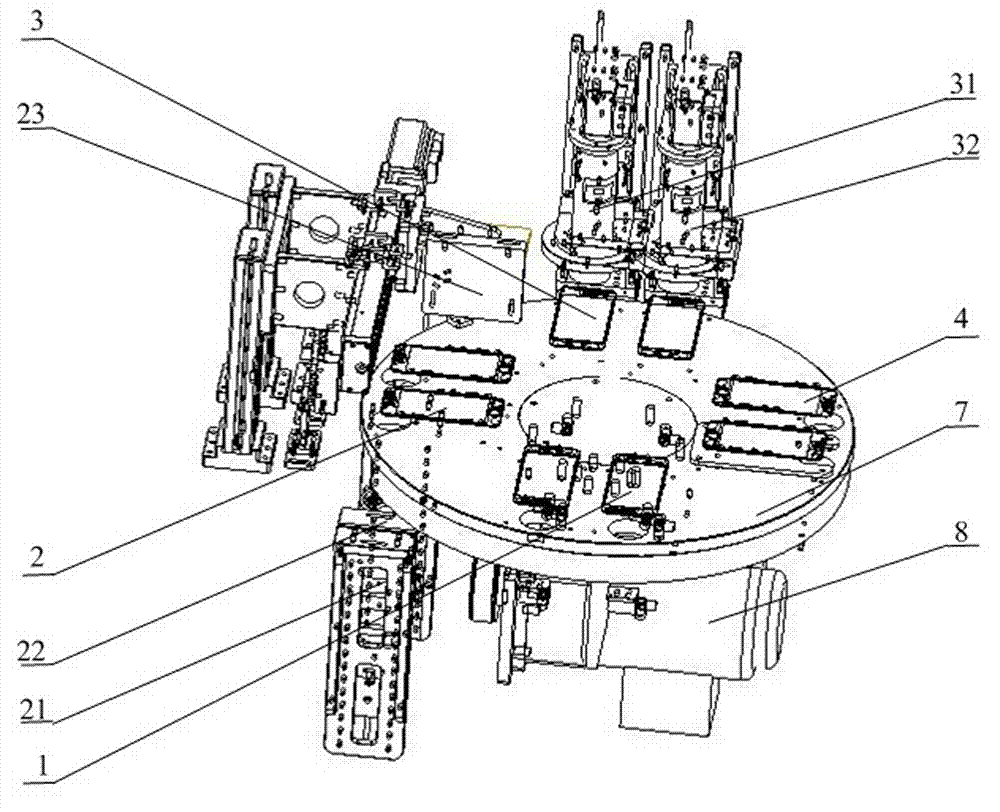

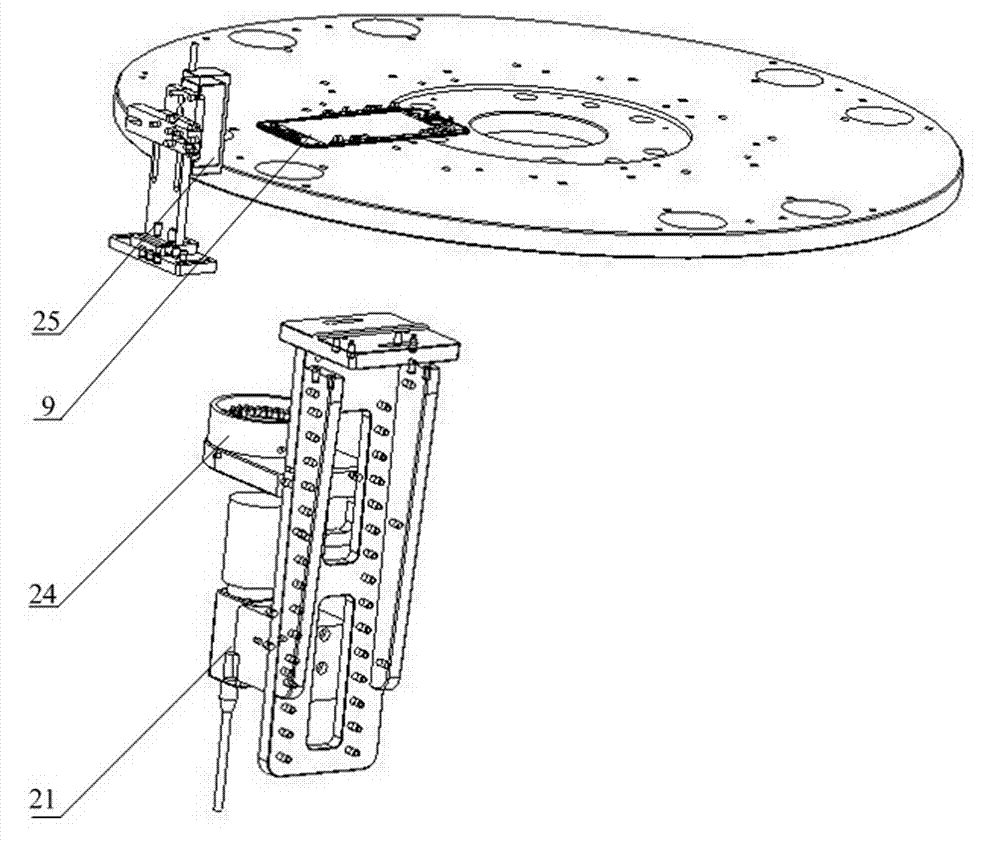

[0016] Figure 1~Figure 4 A specific embodiment of the multi-CCD and line laser-based turntable multi-station high-precision detection device of the present invention is shown, which includes a frame 5 and a horizontal workbench 6 arranged on the top of the frame. The horizontal workbench 6 is provided with a discharge station 1 , a first inspection station 2 , a second inspection station 3 and a receipt station 4 sequentially distributed along the circumferential direction. The horizontal workbench 6 is also provided with a divider 7 for transferring workpieces to be detected between the discharge station, the first detection station, the second detection station and the receiving station. 7 is driven by a servo motor 8 to rotate. The discharge station 1 is provided with a photoelectric sensor for detecting the presence or absence of the workpiece to be detected; the first detection station 2 is provided with a station CCD industrial camera I21, a station CCD industrial came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com