Calibration method of ellipsometer

A technology of ellipsometer and calibration method, which is applied in the direction of polarization influence characteristics, etc., can solve problems such as complex system structure, human adjustment error, and low calibration accuracy of polarizer angle, and achieve simple calibration process, simplified measurement process, and improved measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

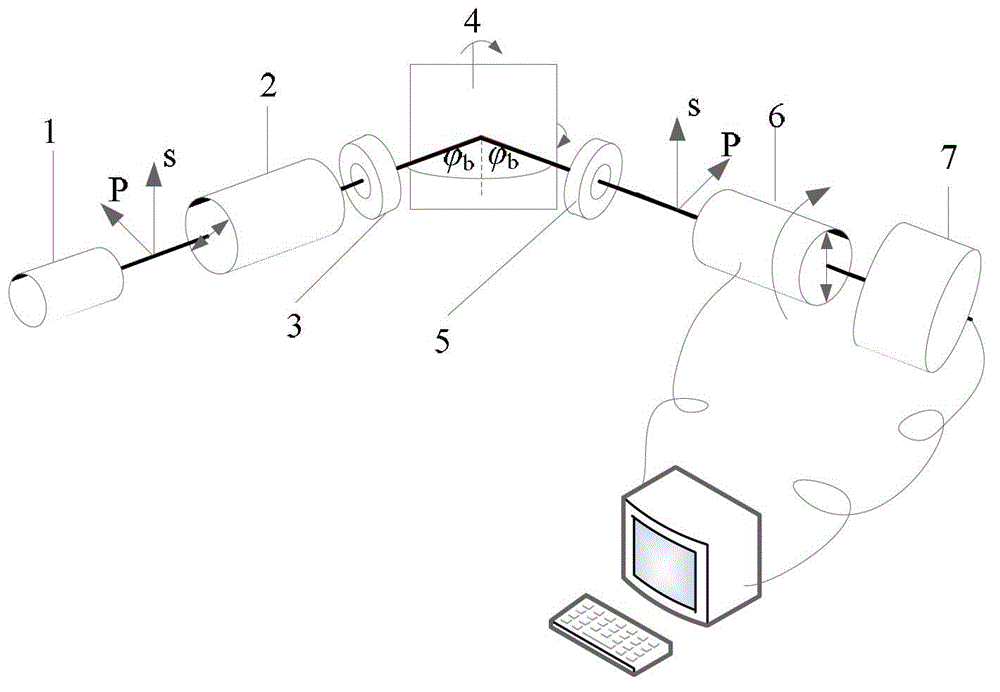

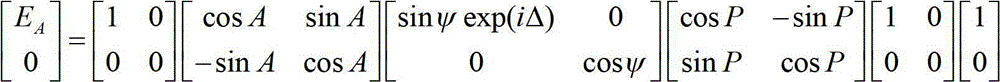

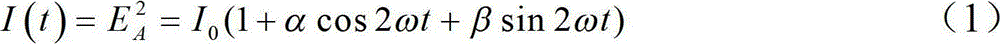

[0115] as figure 1 The shown structure is the ellipsometer of PSA as an example, and the angle calibration method when rotating the polarizer is illustrated through specific steps, which can be divided into the following steps:

[0116] (1) Fix the vibration transmission direction of the polarizer in the ellipsometer. Since the ellipsometer of the rotating polarizer is more sensitive at certain polarizer angles, and the measurement accuracy is higher, it is possible to fix the polarizer with the known approximate transmission direction to an appropriate angle before measurement, For example, make the angle between the transmission direction of the polarizer and the incident surface of the light beam on the reference sample be 45°, that is, make the angle of the polarizer P=45°. In fact, due to the low accuracy of the polarizer's vibration transmission direction, coupled with operational errors, it is difficult for the polarizer's vibration transmission direction to be precise...

Embodiment 2

[0123] as figure 1 The shown structure is the ellipsometer of PSA as an example, and the angle calibration method of the rotating polarizer is illustrated through specific steps, including the following steps:

[0124] (1) Fix the vibration transmission direction of the analyzer in the ellipsometer. Since the ellipsometer of the rotating polarizer is more sensitive at certain angles of the analyzer, that is, the measurement accuracy is higher, the analyzer can be rotated to a suitable angle before the measurement fixed. For example, the angle between the transmission direction of the analyzer and the incident surface of the light beam on the reference sample is 22.5°, even if the angle of the analyzer is 22.5°. In fact, due to the low accuracy of the transmission direction of the polarizer, coupled with operational errors, it is difficult for the angle of the transmission direction of the polarizer to be precisely at this angle, but around this angle.

[0125] (2) Measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com